This comprehensive guide explores Hydac Rf systems, a crucial element in sophisticated machinery management. These systems assist in maintaining optimal functioning of hydraulic systems, crucial for industries ranging from automotive to aerospace. By focusing on streamlined diagnostics and maintenance, Hydac Rf units ensure both efficiency and longevity in demanding operational environments.

Within the landscape of industrial fluid technologies, the Hydac Rf series stands as a beacon of innovation. As global industries lean heavily on hydraulic systems to power machinery, maintaining these systems becomes critical. Hydac Rf devices ensure efficiency and precision, offering users a comprehensive suite of diagnostic and monitoring tools. These systems highlight Hydac's commitment to supporting industries with cutting-edge technology designed to enhance operational effectiveness and reliability. By streamlining hydraulic maintenance and monitoring practices, Hydac Rf devices play a crucial role in addressing the challenges faced by modern industrial operations.

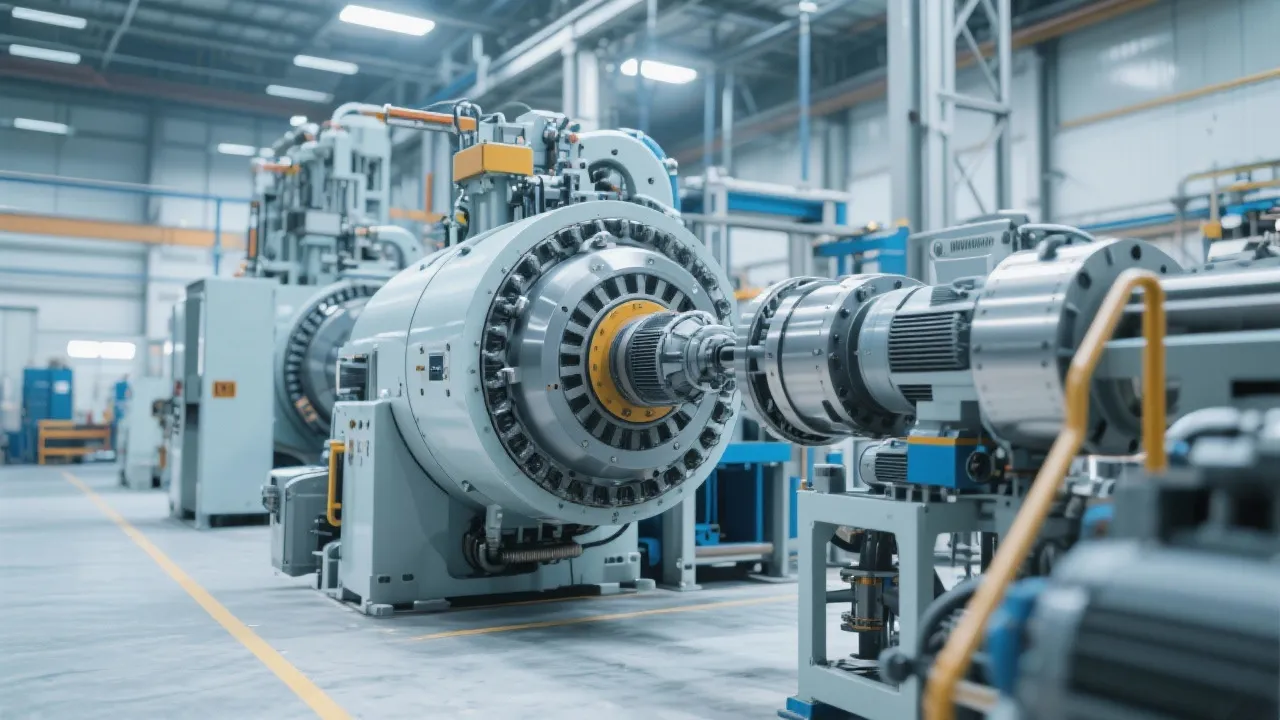

Hydraulic systems are vital across numerous industries, powering equipment ranging from construction machinery to automotive manufacturing lines. By utilizing pressurized fluids, these systems are capable of transferring energy with unparalleled efficiency. Hydraulic technology is indispensable in sectors like mining, agriculture, and transportation, where it provides the necessary force to operate heavy machinery and complex mechanisms.

The basic principle of hydraulic systems rests on Pascal's law, which states that when pressure is applied to a confined fluid, it transmits that pressure throughout the fluid without loss. This property makes hydraulic systems incredibly effective in lifting, pushing, or pulling with minimal energy expenditure. However, their complexity means that regular maintenance and monitoring are essential to avoid costly downtimes and ensure longevity. Factors such as wear and tear, contamination, and environmental conditions can impact hydraulic performance, making it imperative for operators to employ reliable monitoring solutions to maintain system integrity.

Hydraulic systems face unique challenges, including the need for highly efficient operation, safety management, and compliance with industry regulations. Inadequate maintenance can lead to equipment failures that result in not only substantial repair costs but also safety hazards for operators. This is where monitoring solutions like Hydac Rf come into play. They enable operators to maintain high operational standards while mitigating risks associated with hydraulic system failure. The importance of these systems extends beyond mere functionality; they are key components of operational safety and efficiency, ensuring that productivity remains high while minimizing potential disruptions.

Hydac Rf devices integrate seamlessly into these hydraulic systems, offering real-time data analysis and reporting. This functionality is pivotal for spotting inefficiencies and potential failures before they escalate, ensuring machines operate at peak performance while safeguarding investments in technology and infrastructure. Using advanced sensors and wireless communications, Hydac Rf can monitor various parameters such as pressure, temperature, and fluid levels, providing a comprehensive overview of system health.

With capabilities extending beyond simple monitoring, the Hydac Rf series utilizes sophisticated algorithms to analyze trends and predict potential failures. For instance, by tracking historical data, the system can alert operators of abnormal patterns that may indicate impending issues. This predictive maintenance approach not only enhances equipment reliability but also extends the lifespan of hydraulic systems, allowing for optimized capital allocation and reduced long-term costs.

The integration of Hydac Rf systems can be transformative, particularly for organizations aiming to improve their tech stack. Such systems foster an environment of informed decision-making, allowing operators to prioritize maintenance tasks based on urgency and potential impact. As industries face growing pressure to enhance productivity while carefully managing costs, the demand for intelligent monitoring solutions like Hydac Rf is expected to rise exponentially.

| System Type | Features |

|---|---|

| Hydac Rf | Real-time monitoring, comprehensive diagnostics, wireless communication, predictive analytics |

| Basic Pressure Systems | Pressure measurement, basic alerts, no advanced analytics |

| Advanced Fluid Systems | Fluid level, extensive pressure and temperature control, lacks remote communication, limited data interpretation |

This comparative analysis highlights how Hydac Rf stands out not just in the breadth of features but also in the depth of data it provides. Where basic pressure systems may offer any alerts regarding pressure drops or surges, Hydac Rf enhances user understanding through comprehensive diagnostics. It allows users to explore issues more deeply, ultimately leading to an optimized and safer operational environment. The evolution from basic systems to advanced solutions reflects a wider trend in the industry where the ability to gather, analyze, and act on data is increasingly seen as the key to success.

In industries where every second counts, the Hydac Rf suite minimizes downtime and enhances productivity. By automating diagnostics, industry leaders can focus on proactive improvements rather than reactive maintenance, a significant competitive advantage within fast-paced sectors like aerospace and automotive. With production timelines tightening and quality standards soaring, having an accurate view of hydraulic system performance becomes indispensable.

Moreover, Hydac Rf systems not only improve efficiency but also contribute to sustainable operating practices. By decreasing energy consumption through optimized hydraulic performance and reducing waste through predictive maintenance actions, users can achieve environmental targets that are becoming increasingly vital in today’s market landscape. Responsible manufacturing practices that integrate sustainability into operations are more than a regulatory necessity; they are a competitive edge.

Companies leveraging Hydac Rf systems can take full advantage of data analytics to identify patterns over time. For instance, pressure variations monitored over hundreds of operating hours can illuminate opportunities for redesigning certain hydraulic components or altering operational practices to minimize strain on systems. This level of insight fosters an environment where companies can not only respond to issues but also innovate processes, methodologies, and technologies to better serve their clients and fulfill demanding market needs.

The potential development in Hydac Rf systems paves the way for future-proofing industrial operations. With ongoing advancements in IoT (Internet of Things) and AI (Artificial Intelligence), the integration of these evolving technologies promises to revolutionize how data is utilized and interpreted, further bolstering operational efficiency and reliability. IoT integration enables Hydac Rf systems to communicate with other devices, creating a network of interconnected machinery that can share insights and receive commands to optimize performance.

AI-driven analysis will take these capabilities a step further. Looking forward, we can anticipate the emergence of self-adjusting systems that utilize real-time data to modify operational parameters autonomously. For example, if a hydraulic fluid’s temperature rises beyond a predetermined threshold, the system could adjust flow rates or trigger cooling measures automatically. This level of integration not only improves operational efficiency but also enhances safety by minimizing the chances of human error in decision-making processes.

Moreover, with the rise in digital twins—a virtual representation of physical systems—it becomes feasible to simulate hydraulic systems under various scenarios to predict performance outcomes and failures. The combination of Hydac Rf systems with digital twin technology can equip operators with the foresight needed to manage complex hydraulic networks effectively. This synergy may allow businesses to become pioneers in predictive maintenance, transforming how industries perceive and employ hydraulic technology.

Each industry presents distinct challenges that require tailored strategies. In the construction sector, for instance, hydraulic systems operate under extreme conditions and high demands. Dust, dirt, and the potential for mechanical shocks increase the likelihood of system disruptions. Hydac Rf’s robust monitoring capabilities enable operators to maintain real-time awareness of system performance even in challenging environments, allowing for informed interventions when necessary.

In the manufacturing realm, where precision is paramount, maintaining consistent hydraulic performance becomes crucial. Components such as robotic arms and conveyor systems rely on hydraulic forces to deliver speed and accuracy. Any deviations can derail production schedules. With Hydac Rf systems, manufacturers can leverage data analytics to fine-tune hydraulic operations for higher consistency and output quality. The ability to pinpoint issues ahead of time serves to bridge the gap between downtime and productivity.

Transportation and logistics industries also benefit significantly from Hydac Rf systems. As companies rely increasingly on automation, ensuring the reliability of hydraulic systems, such as those found in automated loading/unloading systems, becomes critical. The safety of personnel and the integrity of goods hinge on well-maintained hydraulic performance. Consequently, adopting advanced monitoring systems signifies not just an investment in operational efficiency, but also a commitment to safety and reliability.

Q: What makes Hydac Rf systems stand out?

A: Their capability to provide real-time diagnostic information and wireless communication distinguishes them from traditional hydraulic monitoring systems, allowing for proactive management instead of reactive adjustments.

Q: How do these systems maintain hydraulic efficiency?

A: By offering precise measurements and real-time analysis, they allow the identification and rectification of potential issues before they affect system performance, thus ensuring optimal energy use and functionality.

Q: Are Hydac Rf systems compatible with all hydraulic setups?

A: They are designed to be versatile, fitting into a wide range of hydraulic configurations commonly found in industrial environments, making them an ideal choice for diverse applications.

Q: How do Hydac Rf systems contribute to sustainability?

A: By optimizing hydraulic performance and allowing for predictive maintenance, these systems reduce energy consumption and waste, further advancing companies' environmental goals.

Q: What kind of support and training is available for Hydac Rf users?

A: Hydac offers comprehensive training programs and technical support to ensure users can effectively utilize the systems, maximizing their operational benefits.

With industries continually pushing the boundaries of efficiency and performance, the Hydac Rf systems emerge as essential tools for the modern world. By providing insight and control, they not only protect millions in equipment investments but also pave the way for sustainable, impactful industrial advancements. The future of hydraulic systems lies in embracing sophisticated monitoring solutions that facilitate smarter operational strategies.

As technology continues to evolve, the capabilities of Hydac Rf systems will also expand, integrating even more advanced data analytics and automation features. This evolution will empower industries to transform their processes, improve safety standards, and forge paths toward greater sustainable success. In an era defined by rapid change and technological innovation, adopting robust monitoring solutions like Hydac Rf is not merely advantageous; it is imperative for organizations striving to stay ahead in the competitive landscape.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!