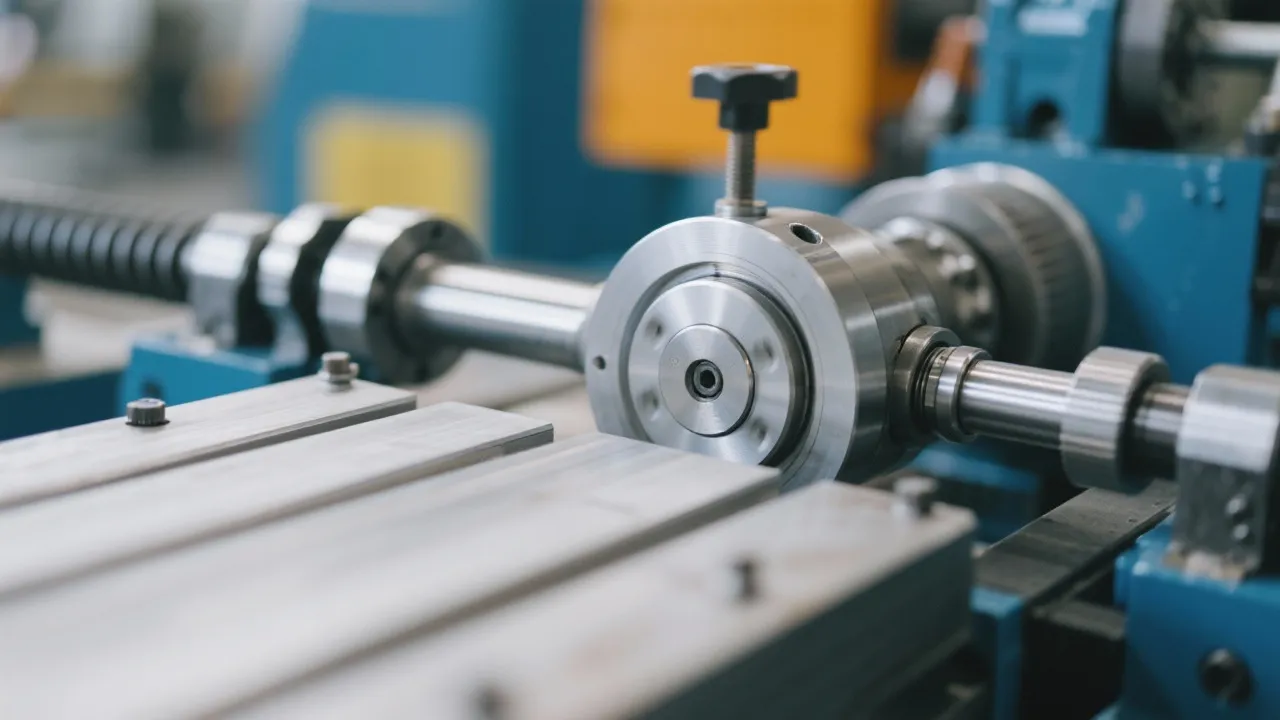

The Rexroth Pwr10 is a pivotal component for industrial machinery, enhancing operational efficiency and effectiveness across numerous applications. It is recognized for its robust design, versatile performance, and integration capabilities within manufacturing systems. This article delves into the intricacies of Rexroth Pwr10, offering insights into its features, benefits, and its influence on industrial processes.

The Rexroth Pwr10 represents a significant milestone in industrial technology. Renowned for its durable construction and high-performance capabilities, this component serves as a cornerstone in systems requiring reliable power management and control. The Pwr10's versatility allows it to be utilized in a variety of settings, from heavy machinery to intricate assembly lines, making it an invaluable asset in the manufacturing sector. As technology continues to evolve, the demand for components that can adapt and perform reliably across various applications has increased. The Rexroth Pwr10 is engineered to meet and exceed these evolving standards, ensuring its relevance and appeal in a constantly changing industry landscape.

At the heart of its widespread acclaim is the Rexroth Pwr10’s ability to deliver consistent performance under demanding conditions. Equipped with cutting-edge technology, it supports seamless integration into existing systems, thus enhancing overall operational efficiency. Industries that rely heavily on automation and precision technologies find the Pwr10 especially useful for its adaptability and synchronized performance with other industrial components. For instance, in automotive production lines, the Pwr10 facilitates rapid assembly processes by providing stable power, allowing robots and automated systems to perform tasks with minimal interruption.

Moreover, the capabilities of the Rexroth Pwr10 extend to sectors such as aerospace and robotics, where precision and reliability are paramount. Its versatility is further illustrated by its use in materials handling systems and conveyor belts, where its power management capabilities can significantly enhance throughput and minimize energy waste. This multifaceted relevance to various industries solidifies the Pwr10's status as a crucial component in modern industrial environments.

The features of the Rexroth Pwr10 underscore its reputation within the industry. Some of the standout characteristics include:

These features translate into tangible benefits such as reduced operational costs, increased machinery lifespan, and improved output quality, thereby delivering exceptional value to industries investing in this technology. The economic impact of using the Pwr10 is compounded by its efficiency enhancements, which allow for more productive use of resources, leading to higher output without a corresponding increase in energy consumption.

| Feature | Rexroth Pwr10 | Competitor A | Competitor B |

|---|---|---|---|

| Power Efficiency | High | Moderate | High |

| Durability | Excellent | Good | Good |

| Integration Ease | Very High | High | Moderate |

From the comparison, it is evident that Rexroth Pwr10 holds a competitive edge due to its superior power efficiency and ease of integration, positioning it as a preferred choice for industry leaders. Additionally, unlike many competitors, the Pwr10 has been designed with future scalability in mind, allowing companies to easily expand their operations without needing to overhaul existing infrastructure. This forward-thinking design represents a crucial advantage in an industry where adaptability and future-proofing are essential for long-term success.

Understanding the practical implications of the Rexroth Pwr10 can be greatly aided by examining real-world applications. Several case studies reveal how this component has transformed operations in various industries.

A renowned automotive manufacturer faced challenges with downtime and inefficient power management on their assembly line. After integrating the Rexroth Pwr10 into their systems, they reported a 20% increase in operational efficiency. The component's advanced power management features allowed for better load balancing across machinery, leading to a significant reduction in energy consumption. As a direct result of this integration, the manufacturer not only improved its production capacity but also achieved greater sustainability by lowering its overall energy usage, aligning with corporate responsibility goals.

An aerospace company specializing in the production of intricate components was struggling with the precision of their automated machining equipment. The introduction of the Rexroth Pwr10 facilitated enhanced synchronization between devices, allowing for a notable reduction in error rates during production. The ability to maintain consistent power supply and control led to a remarkable decrease in material wastage, exceeding 15%, while significantly improving product quality. This case underlines the Pwr10's importance in industries where precision is non-negotiable and showcases how it can contribute to both efficiency and quality enhancements.

A logistics company incorporated the Rexroth Pwr10 into its automated warehousing system. The primary challenge they faced was the high energy expenditures associated with powering a multitude of robotic systems. After deploying the Pwr10, the company experienced a 30% reduction in energy consumption associated with these operations. The power management capabilities of the Pwr10 allowed for intelligent energy distribution, ensuring that energy was only used when required. This improvement not only reduced costs but also enhanced the speed of material handling processes, allowing the company to increase its throughput and better meet customer demands.

With industries moving towards more sustainable and intelligent operations, the evolution of technology like the Rexroth Pwr10 is anticipated to be significant. Innovations are being undertaken to enhance its features further, including the integration of IoT capabilities for better monitoring and predictive maintenance. By linking the Pwr10 to a network of sensors and data analytics platforms, users can gain real-time insights into performance metrics, leading to proactive maintenance scheduling and enhanced operational planning.

Moreover, as green energy solutions become more prevalent, further iterations of the Rexroth Pwr10 could seamlessly integrate with renewable energy systems, maximizing energy efficiency and providing even greater cost savings. This potential transformative capability underscores the importance of investing in such technologies today, ensuring that businesses remain competitive and aligned with future trends.

In a competitive landscape where efficiency and reliability dictate success, the Rexroth Pwr10 stands out as a pivotal solution for industries aiming to enhance productivity and reduce costs. Its ergonomic design, combined with technological advancements, equips it to handle the rigors of modern industrial demands, and ensures that it remains an indispensable asset for the future. As industries continue to evolve with technological advancements, the Rexroth Pwr10 is poised to lead the way in power management innovation, remaining at the forefront of industrial excellence. The investment in such technology not only enhances operational capabilities but also sets the stage for future growth and competitiveness across various sectors.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!