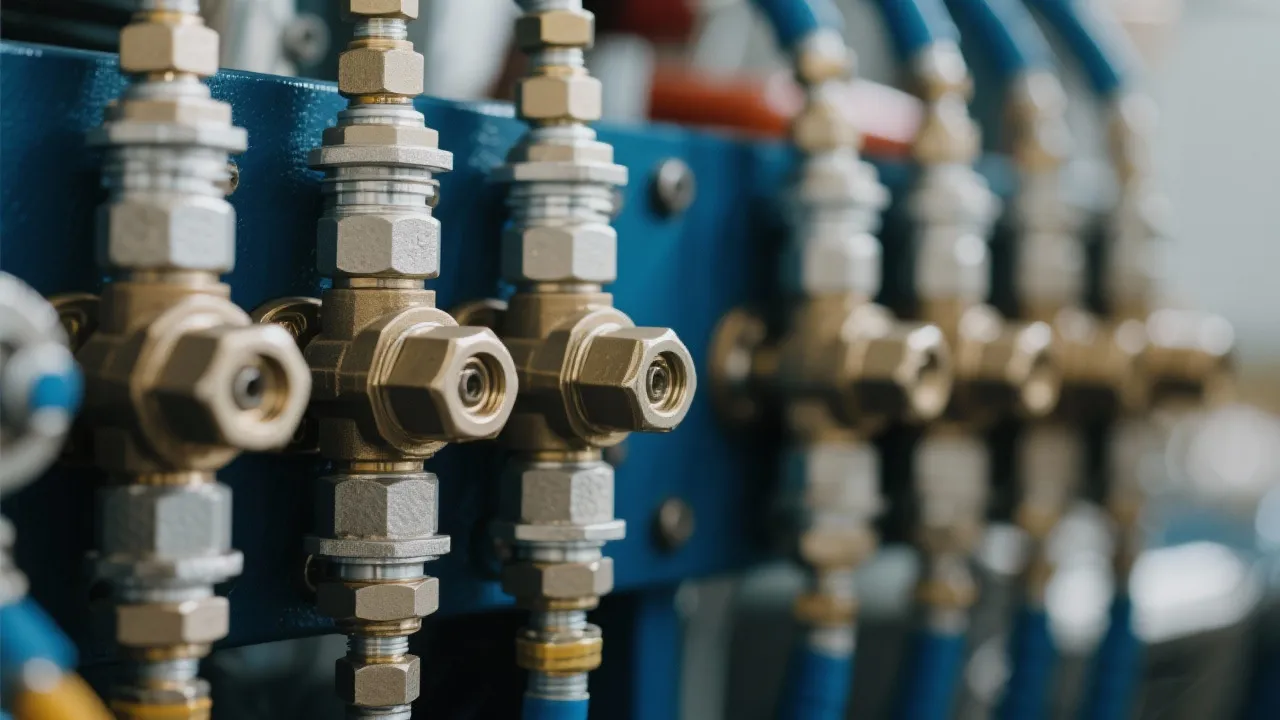

This guide offers an in-depth analysis of Rexroth Dz6dp2, a hydraulic directional control valve widely utilized in various industrial applications. Ideal for regulating hydraulic flow, these valves are known for their precision and reliability. The accompanying article explores their functionality, features, and advantages, providing critical insights for engineers and technicians in the hydraulic industry.

Introduction to Rexroth Dz6dp2 Valves

The Rexroth Dz6dp2 is an essential component in the realm of hydraulic systems, designed to direct and control fluid flow efficiently. These valves are renowned for their robust construction and versatility, making them suitable for a wide range of industrial applications, from manufacturing plants to heavy machinery operations. In this article, we delve into the technical specifications, operational advantages, and practical applications of the Rexroth Dz6dp2 valve. Additionally, we will explore the latest innovations in hydraulic technology, which will further illuminate the role and importance of the Dz6dp2 in modern engineering.

Technical Specifications and Features

At the heart of any fluid power system is the directional control valve, ensuring the proper allocation of hydraulic fluid. The Rexroth Dz6dp2 valve distinguishes itself through several key features:

- Flow Capacity: Capable of managing significant fluid volumes, the Rexroth Dz6dp2 supports efficient hydraulic operations with minimal pressure drops. This characteristic is vital for systems requiring high-speed actuation.

- Size and Porting: Available in various sizes, these valves are adaptable to different system requirements, ensuring compatibility and ease of integration. Their porting options further enhance their versatility, allowing customization based on specific application needs.

- Construction Material: Constructed from high-quality materials such as cast iron or aluminum alloys, the Dz6dp2 is built to withstand harsh industrial environments, reducing wear and prolonging service life. These materials not only enhance durability but also ensure resistance to corrosion.

- Control Options: The valve offers multiple control options, including manual, hydraulic, and electronic, catering to diverse operational needs. Electronic control systems can integrate seamlessly with modern automation solutions, enhancing responsiveness and precision in fluid management.

Benefits of Using Rexroth Dz6dp2 Valves

Incorporating the Rexroth Dz6dp2 into hydraulic systems brings numerous benefits, enhancing system efficiency and performance:

- Precision Control: These valves are engineered for precise modulation of fluid flow, which is crucial in applications requiring meticulous pressure and flow management. This precision is particularly important in systems like robotics, where even minor fluctuations can affect performance.

- Reliability Under Load: They offer consistent performance under variable load conditions, making them ideal for dynamic industrial environments. This reliability is key in sectors where heavy loads are frequently varied, such as manufacturing and construction.

- Ease of Maintenance: Designed with user-friendly interfaces, these valves simplify troubleshooting and regular maintenance procedures, ensuring minimal downtime. Accessibility to service points allows operators to quickly perform maintenance tasks without extensive disassembly.

- Energy Efficiency: By optimizing flow paths and minimizing leakage, the Rexroth Dz6dp2 contributes to reduced energy consumption, promoting sustainable operations. Incorporating this valve can lead to significant cost savings over time, particularly in large-scale applications where hydraulic systems run for prolonged periods.

Applications in Various Industries

The versatile nature of the Rexroth Dz6dp2 valve allows its application across a myriad of industries, showcasing its adaptability and functionality:

- Manufacturing: Essential in assembly lines and robotic control systems, ensuring precise and reliable operation of automated machinery. The precision of the Dz6dp2 allows for optimal synchronization between machinery, reducing bottlenecks and enhancing productivity.

- Construction: Utilized in heavy equipment such as excavators and cranes, providing the necessary control for hydraulic actuators. The ability to withstand extremes of temperature and pressure is particularly beneficial in construction settings.

- Automotive: Integral to hydraulic systems in vehicle manufacturing, enhancing the efficiency of production lines. From stamping to painting, the versatility of the Dz6dp2 enables smoother operations throughout various phases of vehicle production.

- Agriculture: Deployed in farm machinery for various tasks, supporting the efficient management of hydraulic circuits. The ability to perform under varying conditions makes this valve a go-to for modern agricultural equipment, such as combines and tractors.

- Marine: Used aboard ships and offshore platforms, critical for controlling hydraulic winches and related equipment. The robust design of the Dz6dp2 ensures reliable operation in challenging marine environments, where exposure to saltwater and significant vibrations can lead to mechanical failures.

Innovations in Hydraulic Control Technology

As industrial demands evolve, innovations in hydraulic control technology have become necessary for optimizing performance and efficiency. The Rexroth Dz6dp2 valve has kept pace with these advancements. Several trends and technologies are shaping the future of hydraulic systems, further enhancing what the Dz6dp2 can achieve:

- Smart Hydraulic Systems: The integration of IoT (Internet of Things) technology in hydraulic systems allows for smarter monitoring and control. Valves like the Dz6dp2 can now be equipped with sensors that provide real-time data on flow, pressure, and operational efficacy, enabling predictive maintenance and minimizing downtime.

- Advanced Materials: New composite materials are being developed that can withstand higher pressures and provide better corrosion resistance. This not only extends the service life of valves but also enhances performance in extreme conditions.

- Renewable Energy Integration: More hydraulic systems are being designed to operate seamlessly with renewable energy sources, such as solar or wind. The Dz6dp2’s ability to operate efficiently under various pressures means it can be a part of hybrid systems that require flexibility in power sourcing.

- Automated Control Systems: The push towards fully automated production lines has led to greater demand for valves that can integrate with sophisticated control systems. The Dz6dp2's various control options align perfectly with modern automation requirements, making it adaptable for next-generation manufacturing facilities.

Operational Guidelines and Top Practices

To maximize the performance of Rexroth Dz6dp2 valves, adherence to proper installation and maintenance protocols is imperative:

- Correct Installation: Ensure valves are installed according to manufacturer specifications, considering flow direction, and connection types. It is essential to pay attention to the torque specifications of the fittings to avoid cross-threading which can lead to leaks.

- Regular Maintenance: Periodic checks for wear, leakage, and functionality will aid in maintaining optimal valve performance. Establishing a routine maintenance schedule can help in early detection of issues, thus preventing costly downtime and repairs.

- System Compatibility: Confirm that the Dz6dp2 matches the hydraulic system's pressure and flow requirements to avoid operational discrepancies. This includes understanding the system's total hydraulic requirements, including the accumulation of pressure losses in hoses and fittings.

- Fluid Quality and Temperature Monitoring: The performance of the Dz6dp2 valve is heavily influenced by the hydraulic fluid used. Maintaining fluid cleanliness and monitoring the temperature is essential as excessive heat can lead to oil degradation, impacting valve performance and lifespan.

Comparison of Valve Models

| Valve Model |

Flow Capacity |

Control Type |

Applications |

| Rexroth Dz6dp2 |

High |

Manual, Hydraulic, Electronic |

Manufacturing, Construction, Automotive |

| Rexroth Dz4dp |

Medium |

Manual, Hydraulic |

Agriculture, Marine |

| Rexroth Dz10dp |

Very High |

Electronic |

Heavy Machinery, Offshore |

Common Challenges and Solutions

While the Rexroth Dz6dp2 valve is engineered for reliability and performance, operators may face challenges during installation, operation, and maintenance. Understanding these potential issues and their solutions is crucial for optimizing the valve's use:

- Leakages: A common issue in hydraulic systems that can arise from improper sealing or worn-out components. Regular inspection and replacing seals at the first sign of wear can mitigate this risk.

- Pressure Drops: If the Dz6dp2 is not correctly calibrated to match system demand, pressure drops can occur, leading to inefficiencies. Regular performance assessments and adjustments can ensure the valve maintains the necessary operating pressure.

- Contamination: Hydraulic fluid contamination can lead to valve malfunction. Implementing appropriate filtration systems and regular fluid replacement schedules can help prevent contamination issues.

- Incompatibility with System Components: Sometimes, valves may not perform well if they are used with incompatible components within the hydraulic circuit. It’s important to consult with technical specifications to ensure all components can function together effectively.

FAQs

- What maintenance is required for Rexroth Dz6dp2 valves? Regular inspection for leakage and wear, along with timely replacement of seals and components, ensures long-lasting operation. Additionally, fluid quality should be routinely checked to prevent operational issues.

- Can the Dz6dp2 valve be used in both mobile and industrial applications? Yes, its versatility allows it to be used in various settings, including mobile hydraulics and stationary industrial systems. Its robust design makes it adaptable to the dynamic needs of mobile applications.

- How does electronic control enhance valve performance? Electronic control provides precise modulation capabilities, improving response time and system efficiency. It allows integration with various sensors and automated systems for enhanced performance monitoring and control.

- What are the recommended hydraulic fluids for the Dz6dp2? The recommended fluids typically include mineral oils or Biodegradable hydraulic fluids that meet the required specifications for viscosity and thermal stability. It's crucial to adhere to the manufacturer’s guidelines on fluid selection.

- How can I determine if my Dz6dp2 valve is functioning correctly? Monitoring system performance and checking for consistent hydraulic power delivery can indicate the valve's functionality. Additionally, any unusual noise or signs of leakage are clear indicators that further inspection is needed.

Conclusion

In conclusion, the Rexroth Dz6dp2 valve is a pivotal element in hydraulic systems, offering unparalleled control and reliability. Its robust design and diverse application range make it a favored choice among industry professionals seeking efficient fluid control solutions. As advancements in hydraulic technology continue to emerge, the Dz6dp2’s adaptability ensures it remains at the forefront of hydraulic innovation, fulfilling the ever-evolving needs of diverse industries while contributing to increased operational efficiency and sustainability. By understanding its features, benefits, and best practices, operators can leverage the full potential of this exceptional valve, paving the way for enhanced productivity and performance in their hydraulic applications.