This article delves into the complexities and functionalities of Rexroth Valve systems. Renowned for their precision and reliability, these valves are integral components in various industrial applications. With a rich history and a reputation for high-quality engineering, Rexroth Valves continue to lead the market. Read on to explore their role, significance, and the factors that make them a top choice for industries worldwide.

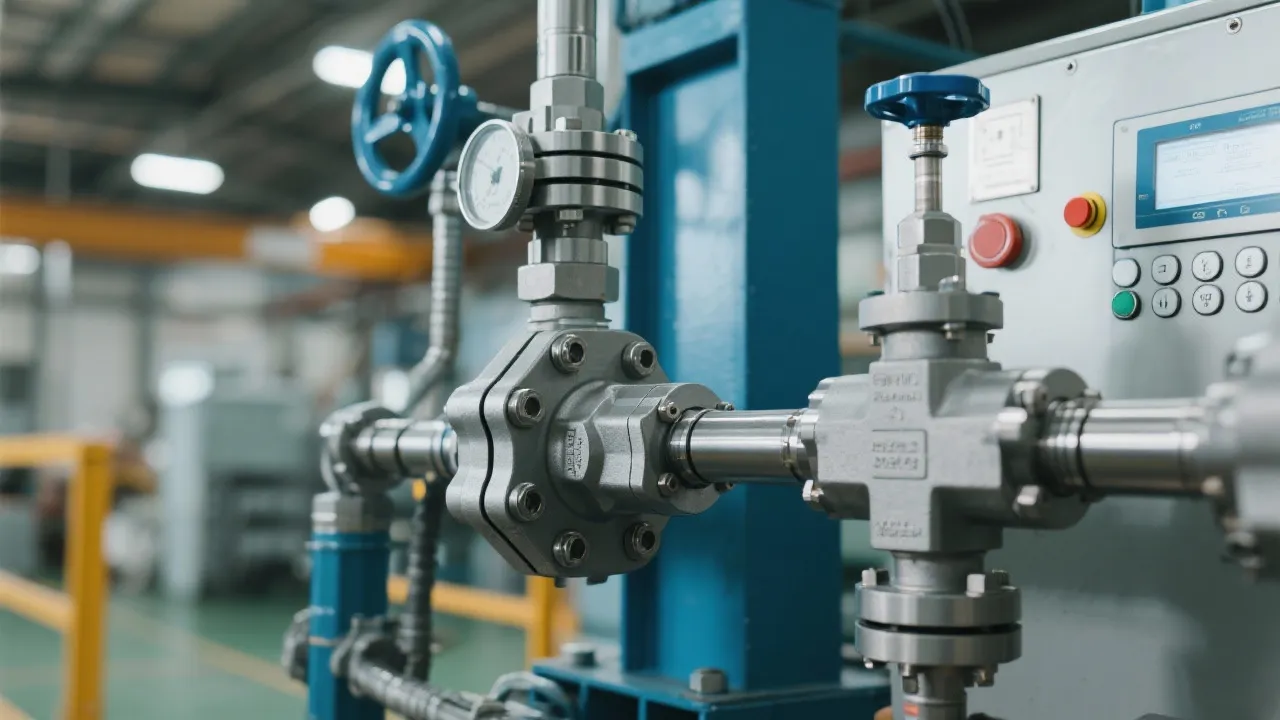

The Rexroth Valve system is a cornerstone in modern industrial applications, providing unparalleled precision and reliability. Known for their engineering excellence, Rexroth Valves are integral to efficient operations in sectors ranging from manufacturing to energy. Their innovative designs and advanced technologies ensure that they meet the varying demands of complex hydraulic systems, adapting fluid dynamics to optimize performance. As industries evolve with increasing automation and stricter efficiency standards, Rexroth Valves remain at the forefront, continuously transforming how industries approach hydraulic control.

Rexroth Valves are essential components that control the flow and pressure of fluids within hydraulic systems. Their applications span various industries, including automotive, aerospace, and manufacturing, where they contribute to operational efficiency and safety. In the industrial landscape, these valves help manage the movement of hydraulic fluid, directing it to various actuators, cylinders, and motors within a system. The precision with which these valves operate ensures that machinery functions smoothly and safely, preventing mechanical failure that could result from fluid overload or misdirection.

The functionalities of Rexroth Valves include not only flow direction but also the regulation of pressure, which is critical for maintaining safe operating conditions. In environments where heavy machinery is in use, such as construction sites or manufacturing plants, ensuring that hydraulic systems function reliably can significantly reduce downtime and maintenance costs. With industries facing pressures to improve productivity and reduce waste, the integration of Rexroth Valves within systems is becoming increasingly common.

Rexroth Valves are utilized across multiple sectors. In the automotive industry, they ensure smooth operation of hydraulic systems in vehicles. In aerospace, they contribute to the precise functioning of aircraft systems. Manufacturing processes heavily rely on these valves for controlling machine operations. The versatility in their design allows Rexroth Valves to perform a variety of tasks across different applications, which extends their usability further.

In the automotive industry, Rexroth Valves are crucial for the functioning of hydraulic brake systems and power steering systems. With more autonomous features being incorporated into modern vehicles, the role of these valves has expanded, requiring more sophisticated valve designs that can handle complex hydraulic needs. Advanced applications, such as active suspension systems, further demonstrate how vital Rexroth Valves are in ensuring vehicle stability and passenger comfort.

Aerospace applications demand the utmost reliability and precision, both of which are guaranteed by Rexroth Valves. In aircraft, the hydraulic systems are responsible for the operation of critical systems including landing gear, wing flaps, and thrust reversers. Rexroth’s emphasis on quality control ensures that each valve can withstand the extreme conditions of flight while maintaining performance integrity under high pressure and altitude variations.

In manufacturing, Rexroth Valves are essential for the functioning of automated machinery, robotics, and assembly lines. They manage the flow of hydraulic fluid in machines that require high-speed actuation, allowing for greater precision in manufacturing processes. With industries moving towards more automated solutions, integrating Rexroth Valves into robotic systems provides the necessary control to perform intricate tasks with efficiency and reliability.

| Industry | Application | Benefits |

|---|---|---|

| Automotive | Hydraulic systems in vehicles | Enhances vehicle control and efficiency |

| Aerospace | Aircraft hydraulic systems | Ensures safety and precision |

| Manufacturing | Machine operation control | Optimizes production processes |

| Construction | Heavy machinery operation | Improves reliability and reduces downtime |

| Marine | Control of hydraulic systems on ships | Facilitates maneuverability and operational efficiency |

| Energy | Hydraulic systems in power generation | Enhances operational safety and efficiency |

What are the main types of Rexroth Valves? The primary types include directional, pressure, and flow control valves, each serving distinct functions within hydraulic systems. Directional valves control the route that fluid takes, pressure valves maintain system pressure, and flow control valves regulate the speed of actuators and cylinders.

Why choose Rexroth Valves over competitors? Rexroth Valves are known for their quality, precision, and durability, making them a preferred choice for rigorous industrial applications. The combination of innovative design and rigorous testing ensures that Rexroth products perform reliably in demanding conditions.

How can Rexroth Valves improve system performance? By providing precise control of fluid dynamics, Rexroth Valves can optimize machinery operation, minimize energy losses, and enhance overall production efficiency. When installed in hydraulic systems, they help reduce unnecessary strain on components, thereby extending equipment life and lowering operational costs.

What maintenance practices are recommended for Rexroth Valves? Regular inspections to check for leaks, wear, and proper functioning are critical. It is also advisable to maintain clean hydraulic fluid and follow the manufacturer’s recommendations for servicing and replacing components when necessary to ensure optimal performance.

Can Rexroth Valves be customized for specific applications? Yes, Rexroth offers a range of models and configurations allowing for customization according to specific application needs. This includes variations in flow rate, pressure ratings, and materials suitable for specific environments, ensuring that users can find the right solution for their unique system requirements.

Rexroth Valves represent a pinnacle of engineering excellence, offering high performance and durability. Their role in enhancing industrial operations cannot be overstated, making them indispensable across multiple sectors. The continuous innovation and reliability of Rexroth Valves ensure they remain a leader in the hydraulic systems market. As industries adapt to growing demands for reliability and efficiency, the integral systems featuring Rexroth Valves will drive advancements in technology and operational practices. The legacy of Bosch Rexroth and its commitment to quality serves as a foundation for future developments in fluid control technology, continuing to set the standard for others in the industry.

Information on Rexroth Valves can be corroborated through industry reports and technical documentation provided by Bosch Rexroth, a reputable manufacturer and distributor. Furthermore, additional academic journals and industry publications detail the technological advancements within the field of hydraulic systems and fluid dynamics, offering a broader understanding of how Rexroth products integrate with and enhance industrial capabilities.

The future of Rexroth Valve technology appears promising, with ongoing research and development focused on improving system integration, energy efficiency, and automation capabilities. One noteworthy trend is the increasing emphasis on digitalization within hydraulic systems, often referred to as Industry 4.0. As factories and plants become smarter, the integration of smart valves, which can communicate with other system components and make real-time adjustments, will play a crucial role in enhancing operational performance.

As industries embrace the Internet of Things (IoT), Rexroth is likely to advance its technology to include smart valves equipped with sensors and communication interfaces. These valves can monitor system parameters such as pressure, temperature, and fluid quality, enabling predictive maintenance and reducing unplanned downtime. The real-time data collected from smart valves can be used to analyze system performance, identify inefficiencies, and implement corrective measures swiftly, thus optimizing productivity.

With global focus shifting towards sustainability, energy efficiency in hydraulic systems has become paramount. Rexroth is at the forefront of this initiative, exploring alternative materials and technologies that minimize the ecological impact of hydraulic systems. The development of valves that require less energy to operate, or that facilitate regenerative braking energy recovery in mobile applications, will contribute to a greener industrial landscape.

The demand for customized hydraulic solutions is on the rise as industries seek to optimize their unique operational needs. Rexroth has responded to this trend by offering modular valves that can be tailored to specific requirements. These modular solutions enable businesses to scale up or down based on their changing needs without undergoing significant system overhauls, thereby reducing costs and downtime.

Additionally, Rexroth recognizes that effective training and support are critical in maximizing the performance of their products. Providing extensive training programs for operators and maintenance personnel can enhance overall system effectiveness and reduce the likelihood of operational errors. With knowledgeable workers, the efficiency gains from implementing advanced hydraulic systems can be fully realized, leading to better performance and productivity outcomes.

Finally, Rexroth continues to engage in collaborations and partnerships with other players in the hydraulic systems and automation sectors to drive innovation and share best practices. By working closely with academia, businesses, and industries, Rexroth seeks to remain ahead of trends and ready to adapt their products to meet future challenges.

Rexroth Valves are more than mere components within hydraulic systems; they are a vital part of a broader ecosystem of industrial efficiency and automation. Their precision, reliability, and innovative nature make them indispensable for various applications across many sectors. As industries look toward the future, the evolution of Rexroth Valves and their integration into advanced manufacturing practices will undoubtedly play a pivotal role in shaping the efficiencies of tomorrow's industrial operations. With Bosch Rexroth continuing to lead in hydraulic solutions, the focus will remain on creating technologies that improve operational safety, efficiency, and sustainability, reinforcing their commitment to quality and innovation.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!