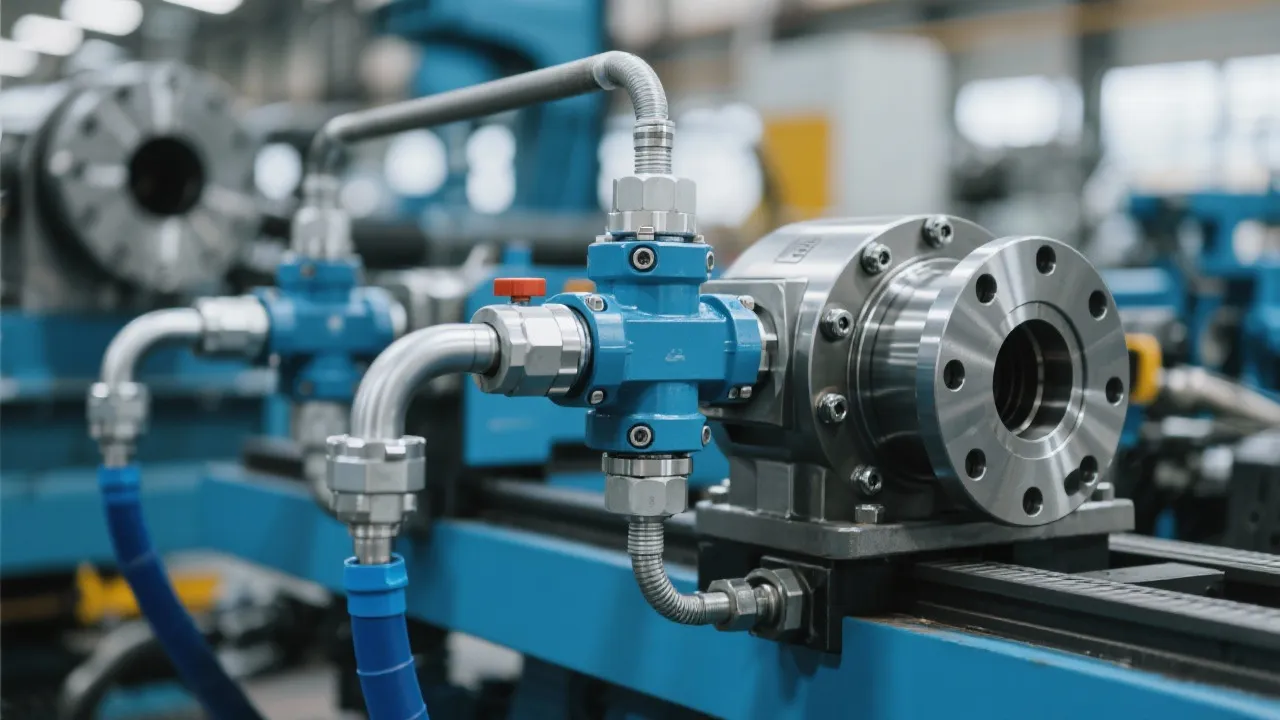

This article delves into the intricacies of Rexroth 7291, an essential component in hydraulic systems renowned for its reliability and performance in industrial applications. Rexroth, a key player in the hydraulics industry, consistently delivers engineered products that meet demanding operational standards, including the 7291 series, popular for its robust design and precision.

The Rexroth 7291 is a hydraulic component that plays a crucial role in the efficient functioning of industrial machinery. Widely recognized for its durability and precision, this component is part of Bosch Rexroth's extensive lineup, a brand synonymous with innovative hydraulic solutions. Established in the early 20th century, Bosch Rexroth has dedicated itself to engineering excellence, ensuring their components not only meet but exceed the dynamic demands of modern industrial applications.

Hydraulic systems are integral to many industrial applications, offering unmatched power and efficiency. They convert fluid power into mechanical power, ensuring smooth and reliable operation in various machinery. These systems utilize pressurized fluid to perform work, which can include lifting heavy loads, moving equipment, or even facilitating complex manufacturing processes. Rexroth 7291 stands out in this realm due to its innovative design and superior performance characteristics, enabling it to effectively transmit hydraulic force with minimal energy loss while maintaining operational safety.

The technology behind hydraulic systems involves various components, such as pumps, actuators, valves, and hydraulic cylinders. Each plays a specific role in ensuring fluid movement and pressure control. Rexroth 7291 fits into this landscape as a critical component—its design incorporates cutting-edge technology that allows it to function efficiently with different types of hydraulic oils, further enhancing compatibility and performance across various applications.

Rexroth 7291 is engineered to meet strict operational requirements, featuring robust materials that withstand high pressure and extensive use. Key attributes include a compact form, efficiency in fluid transmission, and compatibility with a range of machinery. These features make it a preferred choice among engineers and technicians overseeing industrial operations.

The technical specifications of the Rexroth 7291 include attributes such as:

With these specifications, Rexroth 7291 can be seamlessly integrated into existing setups, providing engineers and designers with the confidence that they are using a state-of-the-art hydraulic solution.

| Parameter | Rexroth 7291 | Competitor A | Competitor B |

|---|---|---|---|

| Material | High-grade steel | Alloy blend | Composite |

| Efficiency | High | Medium | Medium |

| Durability | High | Medium-High | Medium |

| Operating Pressure | Up to 350 bar | Up to 300 bar | Up to 250 bar |

| Weight | Lightweight | Moderate | Heavy |

From this comparison, it is evident that Rexroth 7291 excels in various key parameters such as material quality, efficiency, and operating pressure. Its lightweight design combined with high-grade materials contributes to smoother operations and enhanced equipment life. These factors not only reduce the overall power consumption of hydraulic systems but also lead to cost savings for end-users in the long term.

Rexroth 7291 complies with international hydraulic standards, ensuring it meets performance metrics crucial for safety and efficiency. Certifications such as ISO 9001 for quality management and ISO 14001 for environmental management reinforce its reliability in critical operations. These certifications are indicative of Bosch Rexroth's commitment to not only meeting industry standards but also leading the way in sustainable and responsible manufacturing practices.

Moreover, the Rexroth 7291 is also designed in adherence to the latest industry regulations regarding safety and efficiency, such as the Machinery Directive (2006/42/EC). This directive outlines essential health and safety requirements not only for machinery but also for components used within those machines, ensuring that operators and maintenance personnel benefit from enhanced safety standards.

While exceptionally reliable, integrating the Rexroth 7291 into existing systems requires careful planning and skilled personnel to maximize performance. Understanding system compatibility and maintenance needs is crucial for longevity and operational excellence. Various challenges may arise, such as:

Recognizing and addressing these challenges during the planning and implementation stages can significantly mitigate risks and contribute to the overall success of the hydraulic system's performance.

Regular maintenance is essential to ensure the optimal performance of Rexroth 7291. Bosch Rexroth offers extensive support, providing guides and services to facilitate this process, ensuring users can maintain system integrity and operational efficiency. Their customer support services encompass:

Overall, ensuring that proper maintenance protocols are followed is indispensable. It not only enhances the performance of the Rexroth 7291 but also safeguards against premature wear and costly repairs, assuring that operations remain cost-effective and efficient.

It serves as a hydraulic component designed for high-efficiency operation in heavy machinery. Its primary function is to enhance the performance of hydraulic systems, ensuring that industrial equipment operates smoothly and effectively.

Rexroth 7291 is known for its high durability, outperforming many competitors thanks to its superior material quality. The high-grade steel construction withstands harsh conditions, providing long-lasting performance even under the most demanding applications.

While versatile, its integration should be evaluated based on system compatibility and technical specifications. Specific hydraulics systems may require adjustments or modifications to incorporate the Rexroth 7291 efficiently.

Regular inspections, cleaning, and fluid changes are key maintenance practices. It is also important to monitor performance indicators and rectify any unexpected changes in pressure or flow rate.

Yes, Bosch Rexroth provides warranty coverage on their products, subject to terms and conditions that typically include clauses regarding proper installation and adherence to maintenance guidelines.

In the world of hydraulic components, Rexroth 7291 stands out for its performance and reliability. It is an essential component that contributes significantly to the efficiency of various industrial applications, reinforcing Bosch Rexroth's reputation as a leader in hydraulic technology. As industries continue to evolve and require more effective solutions, the Rexroth 7291 remains pivotal in advancing hydraulic systems’ capabilities and performance.

In summary, companies integrating the Rexroth 7291 into their operations are not just making a component choice; they are investing in a solution backed by decades of engineering expertise. As they harness the power of this hydraulic powerhouse, businesses can look forward to greater productivity, enhanced safety, and long-term operational efficiency in their industrial endeavors. The importance of incorporating such innovative solutions cannot be overstated, especially as industries face challenges arising from increasing automation and the push toward sustainable practices in manufacturing. Taking advantage of advanced hydraulic technologies is essential for remaining competitive in the fast-paced industrial landscape.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!