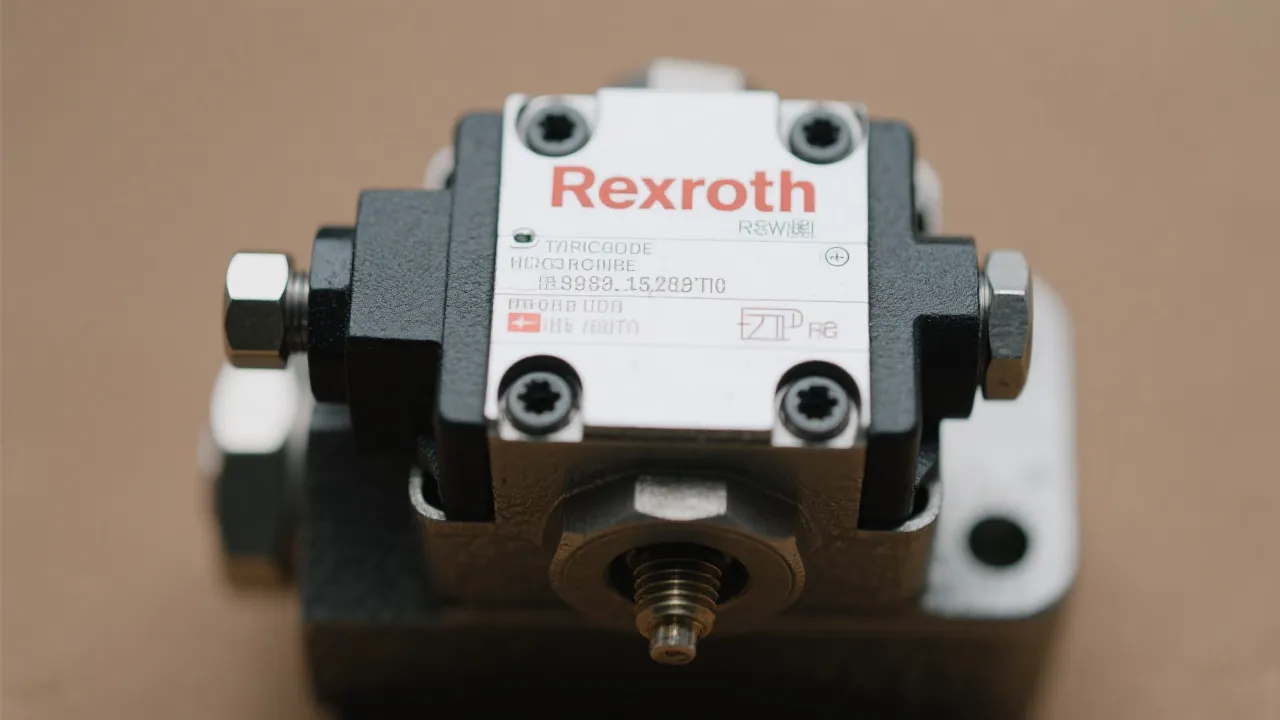

The Rexroth Servo Valve is integral to modern automation, providing precision in fluid control systems, known for its reliability and efficiency. This article delves into its functionalities, benefits, and considerations for implementation, offering a structured analysis to aid readers in understanding its applications in various industries such as manufacturing, aerospace, and automotive sectors.

The Rexroth Servo Valve is a pivotal component in contemporary automation systems, particularly in industries where precision in fluid control is paramount. Recognized for their reliability and efficiency, these servo valves facilitate the modulation of hydraulic fluid flow and pressure, thus playing a critical role in enhancing operational capabilities in sectors like manufacturing, aerospace, and automotive industries. Hydraulic systems extensively utilize these servo valves due to their ability to maintain precise conditions under varying loads and operational demands. As industries increasingly embrace automation and digital transformation, the role of servo valves has only become more critical in achieving high levels of performance and operational efficiency.

Rexroth Servo Valves are renowned for their robustness and precision. Built to withstand rigorous operational demands, these valves offer high dynamic response and feedback resolution. This capability enables rapid adjustments to fluid dynamics, ensuring processes remain stable even under fluctuating conditions. A significant advantage is the capability to drastically reduce system downtime with precise and reliable control, enhancing productivity and efficiency. For instance, the integration of Rexroth Servo Valves in a production line can shorten cycle times and increase throughput, directly contributing to higher profit margins.

Notably, the low hysteresis and linear flow characteristics of Rexroth Servo Valves make them ideal for applications requiring exacting standards of speed and force control. The valves provide a linear relationship between input signal and output flow, facilitating predictable and repeatable outcomes in automated processes. They are crafted to minimize wear and tear, thereby extending service life and offering a cost-effective solution in the long run. This longevity is critical, as it reduces the need for frequent replacements and lowers overall maintenance costs, aligning with modern enterprises' goals of efficiency and sustainability.

The primary applications of Rexroth Servo Valves span across various industries:

When integrating Rexroth Servo Valves into a system, it is crucial to consider factors such as environmental conditions, system compatibility, and maintenance requirements. The precise nature of operation necessitates regular means of feedback to sustain their optimal performance. Environmental factors such as temperature, humidity, and exposure to contaminants can significantly impact the functionality and lifespan of these valves. Therefore, it is essential to assess the operational environment and ascertain the need for protective measures or environmental controls.

Additionally, securing a reliable supplier who can offer both the servo valves and technical support is equally important. The selection of the right supplier not only ensures the procurement of genuine Rexroth components but also provides access to expert advice for installation, maintenance, and troubleshooting. Collaborating closely with manufacturers can also provide insights into industry best practices, enabling companies to stay ahead in fluid control technologies.

Moreover, proper training for the personnel handling these valves is indispensable. This training should cover installation procedures, operational guidelines, and maintenance protocols, ensuring that users are well-equipped to optimize the valves' performance while mitigating operational risks.

Understanding the technical specifications of Rexroth Servo Valves is crucial for effective application and integration. These specifications drive the design and functionality and serve as a guideline for selecting and configuring the appropriate valve for specific applications.

Common specifications include:

While Rexroth Servo Valves stand out due to their advanced technology and reliability, it's essential to conduct a comparative analysis with other valve types, such as proportional valves and on/off valves, to understand their specific advantages and scenarios for application.

Proportional Valves provide variable control of flow and pressure, generally offering lower precision than servo valves but higher compared to traditional on/off valves. They are suitable for applications where precise adjustments are needed but not on the same scale or sensitivity as servo mechanisms. While proportional valves can be cost-effective alternatives in less demanding applications, they cannot match the dynamic response and feedback control that Rexroth Servo Valves offer.

On/Off Valves are straightforward devices that either permit or restrict the flow of hydraulic fluid. While they are highly reliable and less complicated than servo or proportional valves, they cannot control flow rate or pressure levels with high precision. On/off valves are often used in applications where simple control suffices, but in scenarios requiring nuanced adjustments or rapid response times, servo valves are unmatched.

The choice between these types of valves will largely depend on the application's complexity, scale, and specific requirements. In high-precision applications, the additional investment in Rexroth Servo Valves is often justified by the significant performance improvements and long-term operational benefits they yield.

The landscape of automation technologies is constantly evolving, and several trends are emerging that impact the design and deployment of servo valves. Keeping abreast of these trends is essential for manufacturers and operators to leverage new capabilities effectively.

The future for Rexroth Servo Valves appears promising, driven by a combination of technological advancements and an increasing emphasis on automation in various sectors. As industries strive for greater precision and efficiency, the demand for high-performance servo valves is expected to grow.

In the years to come, we may witness more integration of artificial intelligence (AI) in fluid control systems, particularly in understanding and predicting fluid dynamics better. Such advancements could further enhance the capabilities of Rexroth Servo Valves, leading to even more sophisticated control systems that can automatically adjust based on real-time data analysis.

Additionally, as global initiatives focus on reducing carbon footprints, the role of energy-efficient servo valves will be paramount. Manufacturers will continue to invest in research and development to deliver products that not only meet but exceed environmental regulations.

Furthermore, as new markets emerge—such as renewable energy systems (e.g., wind, solar)—the applications for servo valves will expand. Companies will likely develop servo valve solutions specifically tailored for these industries, accommodating the unique fluid dynamics and performance requisites they demand.

In conclusion, understanding the intricate functionalities and advantages of the Rexroth Servo Valve can significantly impact decision-making when deploying automation solutions. These servo valves represent an intelligent investment for industries seeking operational excellence through precision fluid controls. By addressing the various considerations involved in their implementation, organizations can maximize their benefits, ensuring enhanced productivity, efficiency, and sustainability. As technology continues to evolve, the role of Rexroth Servo Valves will not only remain integral but will likely become more pronounced as industries pivot towards more automated and intelligent solutions.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!