This article delves into the intricacies of Rexroth Modular Valves, vital components in hydraulic systems known for their efficiency and versatility. By exploring their functionalities and applications, readers gain insight into how these valves contribute to enhanced performance in industrial settings. Modular valves, a cornerstone in hydraulics, facilitate efficient control of fluid flow, pressure, and direction in various machinery systems.

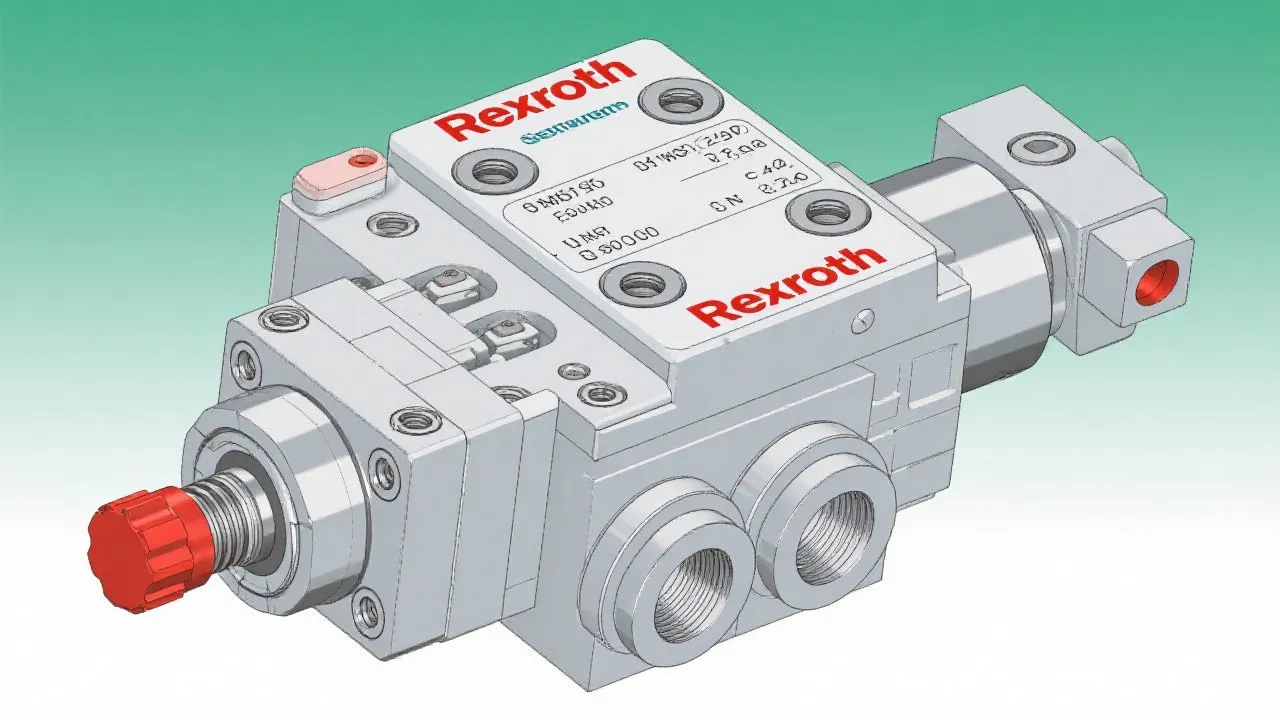

Rexroth Modular Valves play a fundamental role in the realm of hydraulics, providing essential functions in controlling fluid power. Their modular design allows for the integration of multiple components to customize the valve setup according to specific industrial requirements. Developed by Bosch Rexroth, a leader in drive and control technologies, these valves are praised for their precision and reliability. This overview looks at the intricate design and functioning of modular valves, how they optimize hydraulic performance, and their contributions to various industrial applications.

In the industrial sector, hydraulic systems often rely on the perfect balance of fluid dynamics. Rexroth Modular Valves ensure this balance by offering adjustments to cater to pressure control, directional flow, and system stability. These valves are engineered to manage a wide array of hydraulic functions, placing them at the forefront of modern industrial systems. Whether in manufacturing, construction, or assembly lines, they enhance operational efficiency and reduce energy consumption through their superior design.

The significance of these valves extends beyond performance. They contribute to safety by providing reliable control of hydraulic pressure and flow, which minimizes the risk of system failures. In an industrial environment where equipment failures can lead to downtime or even hazardous situations, the reliability of Rexroth Modular Valves becomes paramount.

Rexroth Modular Valves are designed with a variety of features that make them indispensable in hydraulic systems:

The applications of Rexroth Modular Valves are diverse, spanning several industries:

When integrating Rexroth Modular Valves into a hydraulic system, several factors should be taken into account:

| Factor | Consideration |

|---|---|

| System Compatibility | Ensure the valve's specifications align with the system requirements. This includes assessing flow rates, pressure ratings, and overall system design to ensure seamless integration. |

| Maintenance Needs | Regular maintenance is essential to ensure optimal performance and longevity. Establishing a maintenance schedule will help prevent issues from arising and ensure the valves operate at peak efficiency. |

| Cost | Include both initial purchase and lifecycle costs in budget planning. Although Rexroth Modular Valves may have a higher upfront cost compared to non-modular alternatives, their long-term efficiency and reliability can result in significant savings over time. |

| Training and Expertise | Ensure that engineering staff and operators are trained to understand the operation and maintenance of Rexroth Modular Valves. Knowledgeable personnel can better troubleshoot and optimize the system. |

They are advanced hydraulic components designed for customizable control of fluid in industrial systems. Their modularity allows industries to configure systems that meet specific requirements, optimizing performance efficiency.

By providing precise control over fluid dynamics, they optimize power utilization within hydraulic systems. They minimize energy loss, ensuring that hydraulic systems operate smoothly and effectively.

Yes, their design allows for straightforward maintenance, ensuring reliable performance over time. Routine inspections and maintenance can be performed with minimal disruption to operations.

The valves are typically constructed from high-quality steel and aluminum alloys that provide strength, durability, and resistance to corrosion. These materials are selected carefully to ensure that the valves can withstand the rigors of industrial use.

Companies can experience improvements in operational efficiency, reduction in energy costs, and enhanced reliability of their hydraulic systems. The ability to customize configurations also means that they can address specific operational challenges more effectively.

Rexroth Modular Valves stand out as pivotal components in the sophisticated world of hydraulic systems. With their advanced design and reliability, they contribute significantly to the efficiency and effectiveness of various industrial applications, empowering sectors from automotive manufacturing to construction. The versatility, precision, and durability of these valves make them a valuable investment for any industry that relies on hydraulic systems. Furthermore, as companies strive for operational excellence and sustainability, the role of Rexroth Modular Valves will remain crucial in shaping the future of industrial technology.

The future of hydraulic systems is leaning towards greater automation, efficiency, and digital integration. With advancements in technology, the capabilities of Rexroth Modular Valves are evolving to meet the demands of modern industry.

One emerging trend is the integration of Internet of Things (IoT) technology into hydraulic systems. IoT-enabled Rexroth Modular Valves can provide real-time data monitoring and analytics, allowing for smarter system management. For instance, maintenance needs can be predicted before failures occur, which minimizes downtime and extends the service life of the components. Real-time feedback can optimize the performance of hydraulic systems by adjusting fluid dynamics according to operational demands.

Another trend is the move towards environmentally friendly hydraulic fluids, which are less toxic and more biodegradable. Rexroth is researching and developing valves that can operate efficiently with these new fluids while maintaining their high performance and reliability standards. This shift is intended to reduce the environmental impact of hydraulic systems, aligning with global sustainability goals.

Additionally, advancements in materials science are paving the way for lighter, stronger materials to be used in the construction of Rexroth Modular Valves. This will not only enhance durability but also allow for smaller and more compact valve designs, freeing up valuable space in machinery and reducing overall equipment weight.

As industries evolve, the capabilities of Rexroth Modular Valves will continue to expand, providing innovative solutions that enhance the efficiency and safety of hydraulic systems. By embracing these trends, industries can position themselves at the forefront of technological innovation, ensuring that they remain competitive and efficient in an ever-changing market.

Companies around the world have experienced remarkable success by implementing Rexroth Modular Valves into their operations. Several case studies exemplify the profound impact these valves can have on productivity and efficiency.

One notable example comes from an automotive manufacturer in Germany that faced challenges with inconsistent hydraulic pressure in its assembly lines. By integrating Rexroth Modular Valves, the manufacturer achieved a higher level of precision in pressure control, which reduced wastage and improved product quality. The ability to customize valve configurations meant that each station on the assembly line could be optimized for its specific function, resulting in a 20% increase in throughput.

In the construction sector, a major construction company utilized Rexroth Modular Valves in its fleet of excavators and cranes. The enhanced control and durability of the valves allowed these heavy machinery pieces to work more efficiently and reliably in challenging environments. As a result, the company reported a significant reduction in maintenance costs and increased operational uptime, leading to faster project completions and higher profitability.

Additionally, in the marine industry, a shipbuilding company adopted Rexroth Modular Valves for their hydraulic systems operating cranes on their vessels. This shift not only improved control during loading and unloading processes but also enhanced safety measures due to better flow management. The success in operational efficiency led to reduced turnaround times for ships, impacting overall profitability positively.

These examples showcase how Rexroth Modular Valves not only resolve operational challenges but also drive tangible improvements in efficiency, safety, and cost-effectiveness across various sectors.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!