This article delves into the intricacies of LVDT Proportional Valves, offering insights into their functionality, applications, and benefits. LVDT (Linear Variable Differential Transformer) Proportional Valves are crucial in maintaining precise fluid flow in various industrial settings. They ensure accuracy and efficiency in hydraulic and pneumatic systems, making them indispensable components in industries ranging from manufacturing to aerospace.

LVDT Proportional Valves serve as a cornerstone in many technical applications, providing precision in controlling hydraulic or pneumatic fluid flow. A Linear Variable Differential Transformer (LVDT) is integral to these valves, as it assists in the accurate detection of valve position, enabling precise adjustments and enhanced system responsiveness. The mechanistic beauty and operational efficiency embodied in LVDT Proportional Valves have made them indispensable in various engineering domains.

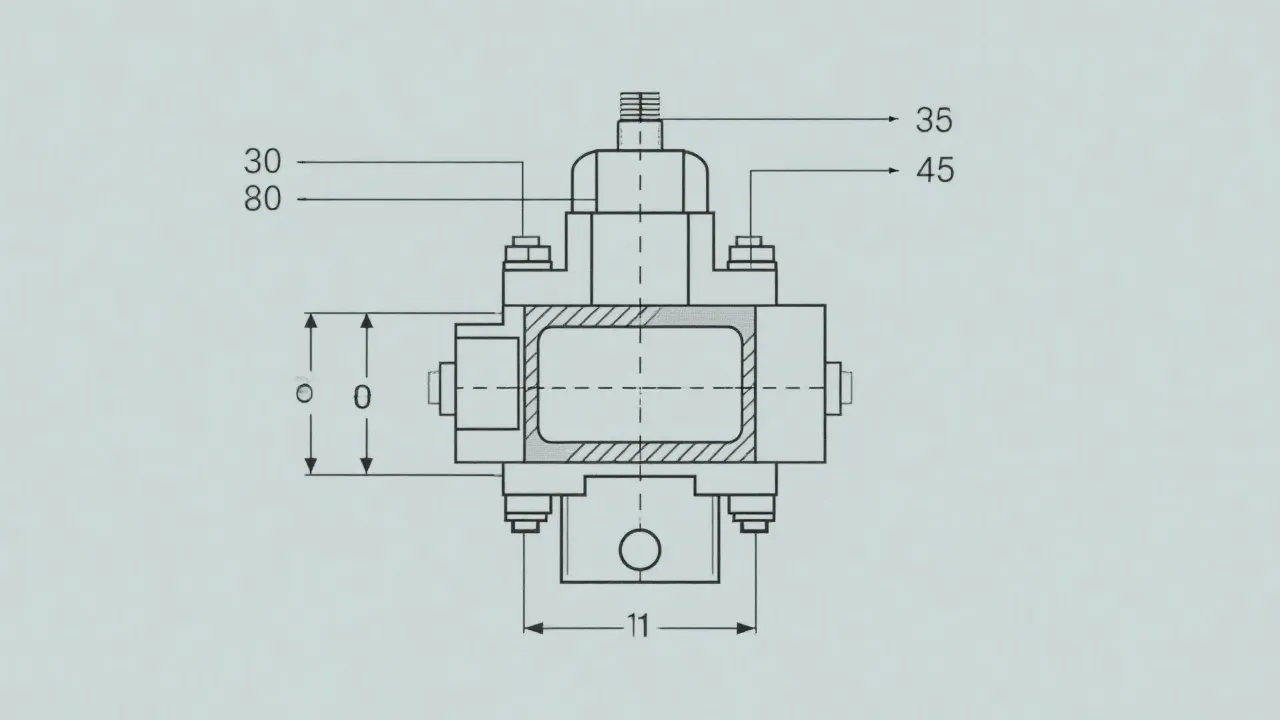

At its essence, an LVDT Proportional Valve facilitates essential fine-tuning in systems where fluid dynamics are pivotal. The valve’s role involves consistent control over variable outputs, which is vital in maintaining smooth operations across various machines and processes. LVDTs are used to measure the position of the valve spool as it moves, translating these movements into significant electrical signals that help maintain operational harmony. The conversion of mechanical movement to electrical signals introduces an automation level that can dynamically adjust to real-time system demands, enhancing overall efficiency.

Moreover, this precision functionality is crucial in applications requiring feedback loops, where the output of the system influences its input. The feedback from the LVDT provides the necessary data to maintain this balance, ensuring the system operates within its designated parameters. For example, in robotics, the movement of actuators can be finely controlled through the modulating characteristics of an LVDT Proportional Valve, maximizing operational effectiveness.

These valves are extensively utilized across numerous industries, notably in sectors where high precision and reliability are non-negotiable. They play a critical role in the aerospace industry, manufacturing processes, and automotive systems, ensuring that operations proceed with minimal errors and optimal efficiency. In aerospace applications, LVDT Proportional Valves regulate hydraulic systems that control the movements of flight control surfaces, where even minute defects in performance can translate to significant safety hazards.

In addition to aerospace and automotive applications, industries such as pharmaceuticals and bioprocessing utilize LVDT Proportional Valves for precise fluid control during manufacturing processes. Accuracy in such environments is paramount, as any deviation can lead to the mishandling of sensitive materials, impacting product integrity and safety.

By modulating fluid flow with superior accuracy, LVDT Proportional Valves reduce wear and tear, consequently extending equipment lifespan and reducing maintenance costs. The reliability of these valves contributes notably to decreasing downtime in production cycles, which translates to enhanced operational profitability. Companies benefit from recurring savings by minimizing maintenance schedules and improving overall process uptime, showcasing the economic value of investing in high-quality LVDT Proportional Valves.

LVDT Proportional Valves present several key advantages over other valve types. Their high sensitivity to positional changes allows for refined control and enhanced system performance. The ability to respond swiftly to adjustments without lag allows them to maintain the desired output, crucial for systems that demand high fidelity in control. Furthermore, these valves are prized for their robustness, often designed to withstand high pressures and harsh environments, thereby ensuring reliable performance in demanding situations.

Durability extends beyond mere resistance to physical factors; LVDT Proportional Valves can also contend with substantial thermal fluctuations and corrosive substances. The materials and construction techniques employed in designing these valves help them perform consistently in production environments that might otherwise compromise lesser components. In addition, their design minimizes the chances of failure points, contributing further to operational reliability.

A particularly advantageous characteristic of LVDT Proportional Valves is the non-contact measurement principle of the LVDT itself, which eliminates mechanical wear between moving parts. This quality not only enhances the longevity of the valve but also ensures that accuracy does not degrade over time, offering consistently robust performance over years of service. In industries where precision is non-negotiable, this reliability can represent a significant competitive edge.

An industry expert notes: "LVDT Proportional Valves have transformed the landscape of fluid control systems. Their ability to provide unparalleled accuracy has revolutionized many facets of industrial operations." As the demand for greater automation and precision in industries grows, the importance of these valves continues to rise. With advancements in sensor technologies and control algorithms, the future of LVDT Proportional Valves is poised for innovation, particularly regarding their integration with smart technologies and IoT applications.

This expert sharing suggests a broader trend toward the implementation of Industry 4.0 practices, where interconnected devices generate vast data streams used to optimize system performance continuously. LVDT Proportional Valves can play a significant role in this ecosystem, providing precise flow control while simultaneously interacting with data-driven analytics platforms that can monitor system health in real-time.

Furthermore, as environmental considerations become more critical, industries are focusing on enhancing energy efficiency. Improved fluid control directly translates to reduced energy consumption, thus aligning with global sustainability goals. LVDT Proportional Valves offer opportunities in developing more eco-friendly systems. In sectors like renewable energy, effective fluid management is essential for optimizing performance and maintaining sustainable operational practices.

As we look toward the future, several trends indicate where LVDT Proportional Valve technology may be heading. One prominent direction is the integration of AI and machine learning into valve control systems. Artificial Intelligence can analyze operational data from LVDT Proportional Valves, predicting necessary adjustments based on system behavior and external conditions without human intervention. This evolution could lead to smarter, more autonomous systems that adapt to real-time demands, significantly increasing operational efficiency.

Another significant innovation lies in materials science. Researchers are investigating advanced materials that improve valve performance, including wear resistance and weight efficiency. The introduction of lighter, yet durable materials could enhance portability for applications in mobile machinery and aerospace applications where every ounce of weight contributes to operational costs and fuel efficiency. Meanwhile, nanotechnology offers potential upgrades to the internal components of these valves, potentially reducing friction and wear while improving sensitivity and response times.

Moreover, as the push for digital twins grows, so too does the importance of accurate modeling and simulation in the design phase for LVDT Proportional Valves. Companies may utilize sophisticated software to create digital representations of these valves and their interactions within larger systems. This ability would enable engineers to predict how changes in design might affect performance before implementation, significantly reducing development time and costs.

Effective maintenance strategies are crucial in ensuring the long-lasting performance of LVDT Proportional Valves. Given their essential role in fluid control, maintaining their integrity not only prolongs their operational lifespan but also ensures that the systems relying on them function optimally. Regular checks for calibration and performance accuracy are necessary to prevent malfunctions and ensure that the output remains within the desired operational parameters.

Additionally, systems should be monitored for any signs of wear and tearing. This can include checking for any debris or contaminants that may impede the performance of the LVDT Proportional Valves or their associated components. Regularly cleaning and replacing any filters in hydraulic systems can help protect the integrity of the valves while enhancing overall system cleanliness.

It is also recommended to conduct training for maintenance personnel regarding the unique requirements of LVDT systems. Understanding the intricacies of these systems allows for more precise upkeep procedures and ensures that any issues can be diagnosed and rectified without unnecessary delays.

In conclusion, LVDT Proportional Valves are instrumental in achieving precise control in fluid dynamics applications. Their design and functionality are tailored to meet the high standards required in modern industries, making them a compelling choice for engineers and technicians aiming to enhance system performance. As industrial systems continue evolving towards greater efficiency and automation, the role of LVDT Proportional Valves is expected to expand further, driven by technological advancements and a growing demand for precision.

The continued exploration and application of these valves in various sectors offer promising insights into how future technological trends will shape the landscape of manufacturing, aerospace, automotive industries, and beyond. As companies seek to optimize their processes, LVDT Proportional Valves will undoubtedly play a central role in these transformative efforts. With ongoing innovation and investment in this technology, the future looks promising for LVDT Proportional Valves and the extensive capabilities they bring to fluid control systems.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!