This article delves into the intricate world of LVDT hydraulic valves, examining their essential role in precise fluid control systems. These components are critical in various industries, offering reliability and accuracy. By dissecting their functionality and applications, we provide a comprehensive guide on how these valves contribute to enhancing system performance and efficiency.

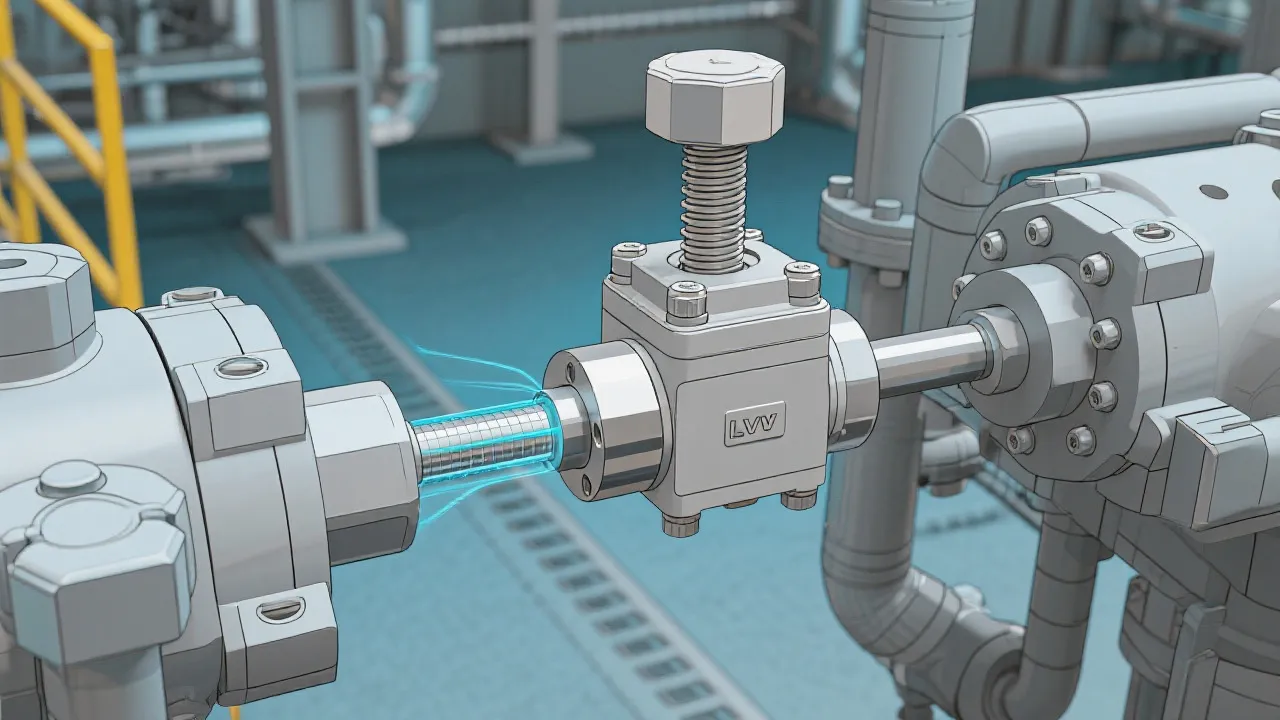

In the realm of industrial applications, the role of precise control systems cannot be overstated. Linear Variable Differential Transformer (LVDT) hydraulic valves are at the heart of these systems, facilitating precise movement and position control. These valves are pivotal in ensuring accurate fluid flow, which is vital for the efficiency and performance of hydraulic systems.

Hydraulic systems operate based on the principle of fluid flow and pressure to perform mechanical tasks. The LVDT component is a type of position sensor that detects the linear displacement of a mechanical element. This sensor helps to provide real-time feedback to the control system, ensuring the accurate adjustment of the valve's position.

LVDT hydraulic valves are lauded for their precision and reliability. They are designed to withstand harsh operating conditions and provide good, maintenance-affordable performance. These features make them invaluable across diverse industrial sectors, including aerospace, automotive, and heavy machinery, where precision and reliability are paramount.

One of the key aspects that enhances their operational excellence is the responsiveness of LVDT sensors. These sensors can detect minute changes in position, allowing for instant adjustments to valve settings. This responsiveness not only improves process efficiency but also ensures safety by minimizing the risk of equipment failure or operational malfunctions. Furthermore, they are engineered with high-quality materials to resist corrosion and wear, extending their functional lifespan significantly beyond that of conventional valves.

The technical advancement of LVDT hydraulic valves includes integration with electronic control units, enhancing functionality and accuracy. This integration allows for more sophisticated control strategies, such as adaptive control and predictive maintenance, which improves overall system efficiency.

One of the standout benefits of using LVDT-controlled hydraulic valves is their non-contact measurement capability, offering high reliability and extended service life. The absence of physical contact reduces wear and tear, ensuring consistent performance even under rigorous conditions.

Furthermore, advancements in digital technology have led to the development of smart LVDT sensors that can communicate with other systems in real-time. These sensors can relay data regarding valve performance, ambient conditions, and fluid characteristics to centralized monitoring systems. Such connectivity not only aids in predictive maintenance but also provides valuable insights into the operation dynamics, allowing for actionable adjustments that can lead to better efficiency and lower overall operational costs.

In today’s industrial landscape, energy efficiency and sustainability are more critical than ever. LVDT hydraulic valves contribute positively in this regard by minimizing fluid leakage and optimizing power consumption. The precision control they offer leads to a significant reduction in energy wastage, translating to lower operational costs and a reduced carbon footprint for industries. As companies strive to meet stricter environmental regulations, the use of LVDT valves aligns with sustainable practices while maintaining optimal performance, thereby supporting green initiatives without compromising productivity.

LVDT hydraulic valves are widely used in industries that demand precise control. In the aerospace sector, they are crucial for the accurate control of flight surfaces and landing gear systems. In automotive manufacturing, they help in precise control of assembly lines and robotic operations.

| Industry | Application |

|---|---|

| Aerospace | Control of flight surfaces and landing gear systems. |

| Automotive | Robotic operations and assembly line precision. |

| Heavy Machinery | Hydraulic actuators and high-load lifting systems. |

| Manufacturing | Precision machining and automated production lines. |

| Marine | Control of valves and actuators in ship hydraulic systems. |

| Energy | Control in hydroelectric plants and renewable energy systems. |

The versatility of LVDT technology fits well within modern manufacturing environments, where process automation and precision are critical. In heavy machinery, these valves are employed in hydraulic lifting systems, ensuring operator safety by providing reliable control even under high-load conditions.

Several notable case studies demonstrate the successful implementation of LVDT hydraulic valves across different industries:

Aerospace Engineering: A leading aerospace manufacturer adopted LVDT-controlled valves in their flight control systems to enhance the precision of control surfaces. By integrating LVDT sensors, they achieved an impressive 30% reduction in response time and significantly improved the overall reliability of flight maneuvers.

Automotive Industry: In the automotive sector, an innovative robotics company implemented LVDT valves in their assembly line operations. The adoption of these valves enabled tighter control over robotic arms, resulting in a 25% increase in assembly line efficiency while lowering energy usage by 15%, showcasing both operational and environmental gains.

Hydraulic Lifting Systems: A construction equipment manufacturer integrated LVDT hydraulic valves into their hydraulic lifting systems, leading to unparalleled precision in elevation control. With LVDT sensors providing real-time feedback, they minimized the risk of accidents and improved operational safety standards across the fleet.

When integrating LVDT hydraulic valves into a system, several factors must be considered: the valve's compatibility with the existing system, the required precision level, and the operating environment. Engineers must also factor in the potential for electronic interference and the need for robust anchoring solutions to ensure stability during operation.

Proper calibration is critical for achieving optimal performance from LVDT hydraulic valves. Regular maintenance checks are also necessary to ensure that the sensors and valve mechanisms are affordable from obstruction or damage, further extending their operational longevity. These maintenance checks can include verifying the linearity of measurement, checking for potential contamination in the hydraulic fluid, and ensuring that the electronic components maintain their robustness against environmental challenges.

Moreover, maintenance teams should be trained to understand the specifics of LVDT technology. This encompasses not only mechanical checks but also managing software settings related to hydraulic controls. Such a comprehensive maintenance approach minimizes downtime and enhances the reliability of the hydraulic systems.

The future of LVDT technology is anchored in continuous innovation. As industries evolve, so do the demands for more efficient, responsive, and intelligent systems. Key trends expected to shape the future of LVDT hydraulic valves include:

LVDT hydraulic valves are essential for industries requiring high precision and reliability. Their integration into hydraulic systems not only enhances performance but also offers good cost savings due to their durability and accuracy. As technology advances, these valves will continue to play a crucial role in industrial automation and control.

The combination of LVDT technology with advanced control systems and smart solutions paves the way for more efficient manufacturing processes, improved operational safety, and sustainable practices across various sectors. The ongoing advancements in sensor technology and digital integration promise to unlock new levels of efficiency and responsiveness, making LVDT hydraulic valves a cornerstone of future industrial innovations.

Whether in critical aerospace applications or vital automotive automation, LVDT hydraulic valves are set to maintain their prominence as leaders in precision control. As industries navigate the ever-evolving technological landscape, investing in LVDT technology could very well represent one of the smartest decisions for companies seeking to enhance their operational capacity and gain a competitive edge in the global market.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!