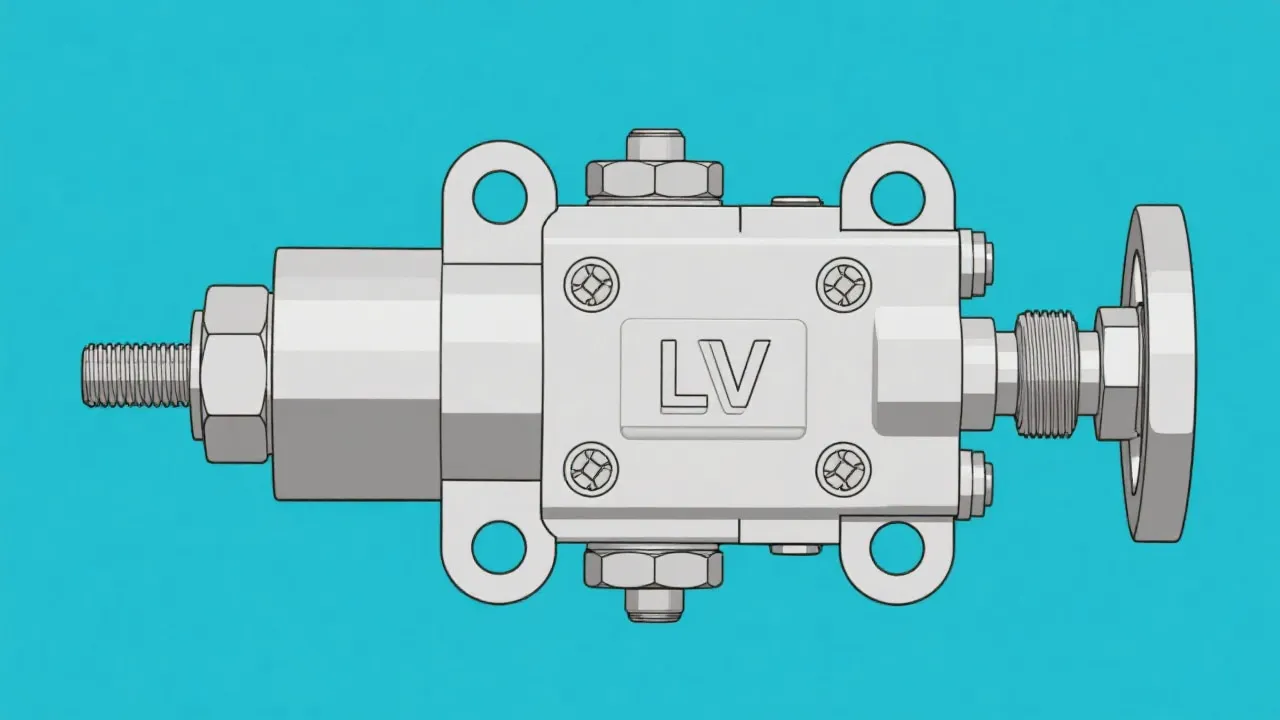

LVDT (Linear Variable Differential Transformer) Hydraulic Valves are crucial components in modern industrial applications. These valves use electric signals for precise positioning and control of hydraulic systems. With their ability to measure linear displacement accurately, they are indispensable in sectors requiring high precision and reliability, ensuring efficient operation and maximizing machinery performance.

The advent of sophisticated technologies has revolutionized various industrial sectors, and one such technological marvel is the LVDT (Linear Variable Differential Transformer) Hydraulic Valve. These valves are integral to modern hydraulic systems, offering unmatched precision and reliability. They are widely used in industries where accurate measurement and control are paramount. The importance of LVDT hydraulic valves cannot be overstated; they serve as critical components in systems requiring intricate control of hydraulic mechanisms, enabling everything from simple machinery operations to complex aerospace applications.

The primary function of an LVDT hydraulic valve is to control the flow and pressure of the hydraulic fluid, ensuring optimal performance of the machinery. An LVDT operates by transforming linear motion into an electrical signal. It comprises a core and a coil assembly, where the core's linear movement within the coil changes the inductance, thereby generating an electrical output proportional to the displacement.

When an external force is applied, the core of the LVDT moves within the coils, altering the magnetic field and thus changing the output voltage signal. This principle allows for precise measurement of linear displacement, making LVDTs exceptionally reliable in various settings. Moreover, their ability to convert mechanical movements into electrical signals opens the door to using advanced feedback systems in hydraulic control applications.

In sectors like aerospace, automotive, and manufacturing, the demand for precision and efficiency is ever-increasing. LVDT hydraulic valves play a pivotal role in these industries due to their capability to provide accurate positional feedback. They are crucial in scenarios involving actuation systems, fluid control processes, and servo mechanisms. For instance, in the automotive sector, LVDT valves are often used in brake systems where precise fluid control is essential for safety and performance.

In aerospace applications, LVDT systems help in cockpit controls and landing gear mechanisms, where they assist in determining the exact position of moving parts. Manufacturing processes, particularly in automated factories, employ LVDT hydraulic valves for quality control and testing of various machinery. These applications highlight the versatility and necessity of LVDT technology across multiple sectors, allowing industries to enhance their overall productivity.

| Feature | LVDT | RVDT (Rotary Variable Differential Transformer) |

|---|---|---|

| Measurement Type | Linear Displacement | Rotary Displacement |

| Usage | Hydraulic valve position control, precision measurement | Rotary position sensing, angular movement measurement |

| Sectors | Aerospace, automotive, manufacturing | Automation, robotics |

While both LVDTs and RVDTs operate on similar principles, the key distinction lies in their application domains and the types of movements they measure. Understanding these differences is paramount for engineers and technicians when selecting the right technology for specific applications.

Despite their advantages, the integration of LVDT hydraulic valves requires careful consideration of factors like alignment, installation space, and system compatibility. Addressing these challenges ensures the optimal performance of the system and extends its operational life. For instance, proper alignment is critical; misalignment can lead to inaccurate readings or even damage to the valve itself. Furthermore, the size and configuration of the components must be suited for the specific application to ensure effective space utilization and performance.

Another challenge is the need for adequate environmental protection, as LVDTs can be susceptible to contamination from dust, moisture, and other entities that might interfere with their functioning. Hence, housings and enclosures designed to protect these valves are often necessary depending on the operational environment. Additionally, electrical interference can pose a problem, especially in high-noise industrial settings. Therefore, proper shielding and grounding must be implemented to guarantee reliable signal integrity.

According to industry reports, the global demand for LVDT systems is increasing steadily. Factors such as advancements in automation technologies and the need for precise control in manufacturing processes are driving this growth. Reliable market studies project a significant rise in LVDT applications in the coming years, with manufacturers investing in research and development for advanced model designs.

The push towards Industry 4.0 and the increasing adoption of IoT in industrial environments are particularly propelling the growth of LVDT hydraulic valves. These technologies demand highly responsive and accurate systems that can provide real-time data for monitoring and predictive maintenance, positioning LVDT solutions as key components in future industrial automation strategies. With more industries looking to optimize operations, the market potential for LVDT hydraulic valves is expanding exponentially. As a result, investment in these technologies could yield significant returns for manufacturers capable of delivering reliable and innovative solutions.

The main advantage is its precision in linear displacement measurement, which is essential for systems requiring exact positioning. This precision empowers engineers to develop systems that can respond rapidly and accurately to changing conditions.

Yes, they are designed to withstand extreme conditions, although specific models are available for exceptionally high temperatures. Some manufacturers specialize in constructing LVDTs that can endure extreme temperatures, making them suitable for applications in sectors like aerospace and heavy industry.

Unlike potentiometers, LVDTs offer non-contact measurement, reducing wear and increasing durability. This aspect makes LVDTs much more reliable over time, as potentiometers can suffer from mechanical wear from friction, leading to less accurate readings.

While LVDTs are known for their low-maintenance requirements, periodic checks for alignment, electrical connections, and protecting enclosures from environmental factors can prolong their lifespan and ensure optimal performance. Keeping an eye on the operating environment is crucial, especially in industries with high dust levels or liquid exposure.

Yes, LVDT valves can be designed for underwater applications, provided they are constructed with appropriate materials to withstand high pressure and corrosion. Specialized coatings and robust enclosures can enhance their durability in such conditions, making them feasible for underwater robotics or marine applications.

The LVDT hydraulic valve stands at the forefront of fluid control technology, offering solutions tailored to the precise needs of contemporary industrial processes. As industries evolve and demand higher efficiency, the role of LVDT in enabling accurate and reliable system operations becomes indispensable. The combination of high precision, reliability, and versatility establishes LVDTs as essential components in many advanced automation systems, fostering innovation and efficiency.

As research and advancements in materials and technologies continue, we can expect LVDT hydraulic valves to become even more capable and adaptable. Manufacturers are continuously exploring new designs that leverage miniaturization and improved signal processing, further enhancing the operational capabilities of these devices. The future of LVDT technology appears bright, with a promising horizon that suggests a vital role in developing smarter, more efficient systems across various industries.

Ultimately, as businesses strive to maintain competitive advantages through precise control and automation, LVDT hydraulic valves will remain a critical cog in the mechanics of modern industrial systems, proving their worth time and again across multiple applications.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!