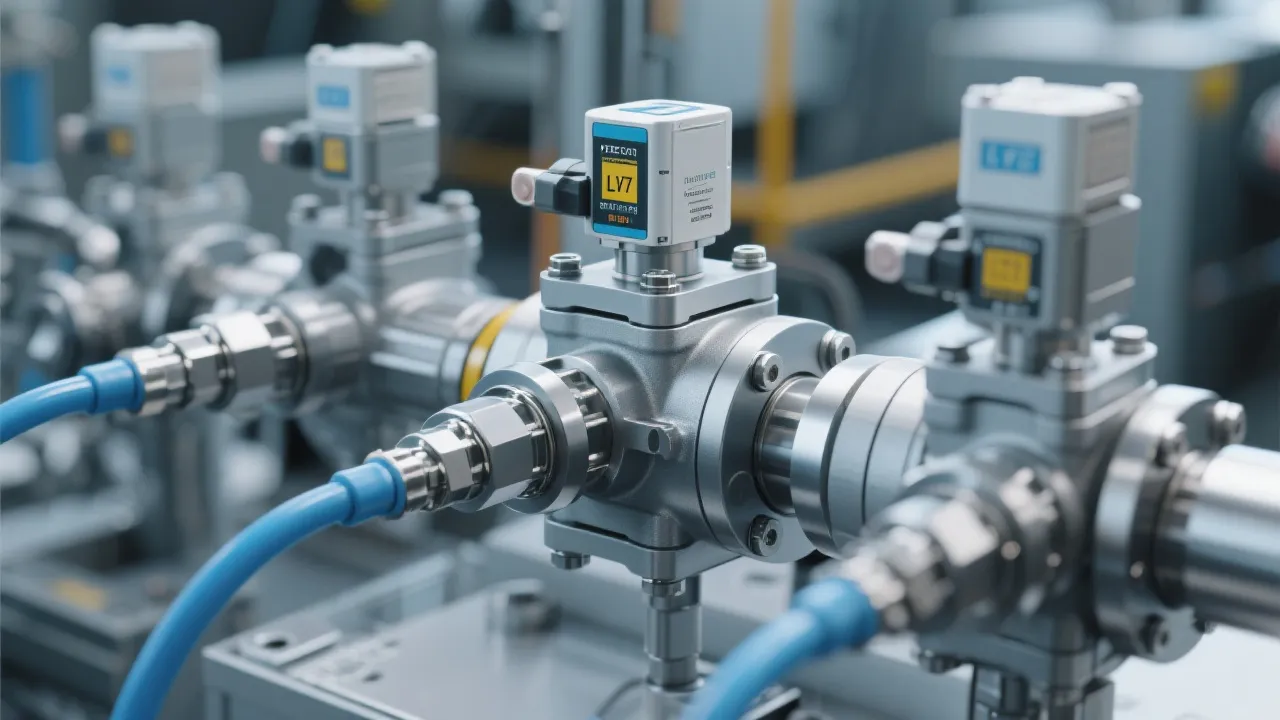

Lvdt hydraulic valve systems are integral components in modern industrial applications, offering precise control and feedback in fluid dynamics. These systems utilize a Linear Variable Differential Transformer (LVDT) to ensure accurate valve positioning, enhancing efficiency and reliability. The article explores the technology's functionalities, benefits, and applications, providing insights into optimal operation and the future of hydraulic systems.

The advent of LVDT Hydraulic Valve systems is a groundbreaking stride in the field of fluid dynamics, offering unparalleled precision and control. These systems leverage the characteristics of a Linear Variable Differential Transformer (LVDT) to regulate hydraulic valves with high accuracy, making them a cornerstone in numerous industrial applications. This article delves into the mechanics, advantages, and practical applications of these systems, presenting a comprehensive guide grounded in expert knowledge.

The Linear Variable Differential Transformer (LVDT) is a type of electromechanical sensor used to convert linear position or motion to an electrical signal. Its core function within a hydraulic valve system is to provide accurate feedback regarding the position of a valve, thereby facilitating fine control over fluid flow. This feedback mechanism is critical in applications demanding precision, such as aerospace, automotive, and manufacturing industries. The mechanism works through a primary coil, which induces a voltage in secondary coils as the core moves within it, producing an output that correlates to the core's position.

The LVDT’s operation is characterized by its simple construction; typically, it comprises a cylindrical body with a movable ferromagnetic core centrally positioned. As the core moves in response to input commands, it alters the magnetic flux linkage, thereby varying the induced voltage in the output coils. This proportional relationship allows for very fine measurements, with resolutions that can measure in the micrometer range. Due to this nature, LVDTs are particularly suited for applications where feedback loops are necessary for maintaining precise control, such as in servo-control systems for hydraulic actuators.

LVDT hydraulic valves bring several advantages to the table, including improved system efficiency, enhanced reliability, and reduced maintenance costs. Due to the nature of LVDT, these valves offer frictionless operation and are resistant to shock and vibration, conditions often encountered in industrial environments. Additionally, the absence of mechanical wear in LVDTs ensures longevity and reduced downtime, which translates into cost savings and increased productivity.

| Benefits | Description |

|---|---|

| Precision | Enables accurate control and positioning of hydraulic valves, essential for meticulous applications. |

| Durability | Exhibits high tolerance to environmental stressors such as shock, vibration, and temperature fluctuations. |

| Efficiency | Minimizes energy loss and optimizes fluid dynamics, leading to enhanced overall system performance. |

Furthermore, the linear nature of LVDTs enables them to function effectively in complex control systems where feedback needs to be accurate and timely. Regular functionality checks of the LVDT components help ensure stability and can prevent unwanted oscillations or erratic behaviors within hydraulic systems. The use of LVDT technology also allows for a high degree of customization, catering to the specific needs of different hydraulic systems while maintaining the core operational benefits.

Hydraulic systems employing LVDT are prevalent in diverse sectors. In the aerospace industry, they are crucial for actuating flight control surfaces. The hydraulic actuation systems, combined with precise LVDT feedback, improve the reliability and responsiveness of control surfaces, contributing to enhanced flight safety and maneuverability. In manufacturing, these systems regulate machinery operations to maintain precision and consistency. LVDT hydraulic valves can manage the operation of robotic arms, conveyor systems, and various automated assembly processes crucial for modern-day manufacturing.

Moreover, the automotive industry relies heavily on LVDT hydraulic valves to manage critical aspects of vehicle dynamics, contributing to advancements in automotive safety and performance. These valves are often implemented in anti-lock braking systems (ABS), where rapid and precise adjustments are necessary to maintain vehicle stability. The integration of LVDT sensor technology enhances the feedback loop for the hydraulic systems involved in braking and steering, resulting in improved vehicle handling and reduced stopping distances.

In the energy sector, particularly in the management of hydraulic systems within wind turbine operations, LVDT technology ensures the control of blade pitch and yaw mechanisms. By providing precise feedback on the position of the blades, the hydraulic systems can make real-time adjustments to optimize performance and efficiency based on wind conditions. This application exemplifies how LVDT hydraulic valves contribute to renewable energy technologies, enhancing efficiency and reliability.

To ensure these systems perform optimally, regular calibration and maintenance are advised. Routine inspections of the LVDT for alignment and integrity can prevent operational discrepancies. Calibration involves adjusting the system to account for any drift or changes in the sensor's performance, enabling it to provide accurate output. Moreover, integrating these systems with advanced digital control units can further fine-tune performance, facilitating real-time adjustments and predictive maintenance strategies.

Incorporating advanced diagnostics can also enhance maintenance protocols. By leveraging IoT technologies, systems can be monitored remotely, providing data analytics that support informed decision-making regarding maintenance actions. The combination of human insight and machine learning can lead to optimized performance over time, extending the lifespan of hydraulic valve systems and minimizing the risk of unexpected failures.

Another optimization strategy involves the proper selection of materials and components. For instance, using corrosion-resistant materials in environments where hydraulic fluids may degrade components can significantly extend the durability of an LVDT hydraulic valve system. Furthermore, employing seals and gaskets that match the system's operating pressures can help maintain integrity under operating conditions, reducing leaks and improving reliability.

Despite the many advantages presented by LVDT hydraulic valve systems, several challenges must be considered during their implementation. One common challenge is the need for adequate environmental protection, particularly when LVDT sensors are used in harsh conditions. Additionally, understanding the installation environment and factors such as temperature fluctuations and exposure to various chemicals is crucial to ensure the long-term stability and accuracy of the system.

Another significant consideration is the integration of LVDT hydraulic valves into existing systems. Retrofitting legacy systems with modern LVDT technology can present compatibility challenges, necessitating a thorough evaluation of current systems and possibly extensive modifications. This integration should also consider the overall control architecture, ensuring that the LVDTs can communicate effectively with existing control algorithms and programs.

Additionally, while LVDT sensors are resilient, they require precise alignment and handling to ensure optimal performance. Any misalignment during installation or operation can lead to inaccuracies in position feedback. Therefore, technicians must employ best practices during installation and regular maintenance checks to ensure that systems remain within specified tolerances.

The future of LVDT hydraulic valve systems is promising, with ongoing innovations aimed at enhancing their capabilities. Emerging technologies such as the Internet of Things (IoT) and smart sensors are poised to further integrate with hydraulic systems, providing insightful data analytics and remote operation features. Such advancements are expected to elevate the precision and functionality of hydraulic systems across industries.

As industries increasingly embrace automation and seek to enhance operational efficiencies, the role of LVDT technology is likely to grow. Advanced machine learning algorithms paired with LVDT sensor data can pave the way for predictive maintenance solutions that anticipate failures before they occur, thus minimizing downtime. The use of big data analytics can uncover operational trends that help engineers design better-performing systems tailored to specific operational environments or applications.

Moreover, the potential for integrating artificial intelligence into LVDT hydraulic systems signifies a considerable leap forward. AI algorithms can analyze real-time data speeds and environmental variations to fine-tune valve positions dynamically. Such systems may offer improved adaptability to changing conditions, leading to enhanced performance and productivity. Future innovations might even introduce self-diagnosing systems that can alert operators to potential issues in real time, thus enhancing the overall accountability and performance of hydraulic systems.

In conclusion, the adoption of LVDT hydraulic valve systems marks a significant evolution in hydraulic technology, offering solutions that are more precise, reliable, and efficient. These systems have become essential in various industries, where they dictate safety, performance, and operational efficiency. As industries continue to evolve, these systems will likely play an increasingly vital role in shaping the future of fluid dynamics and industrial automation.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!