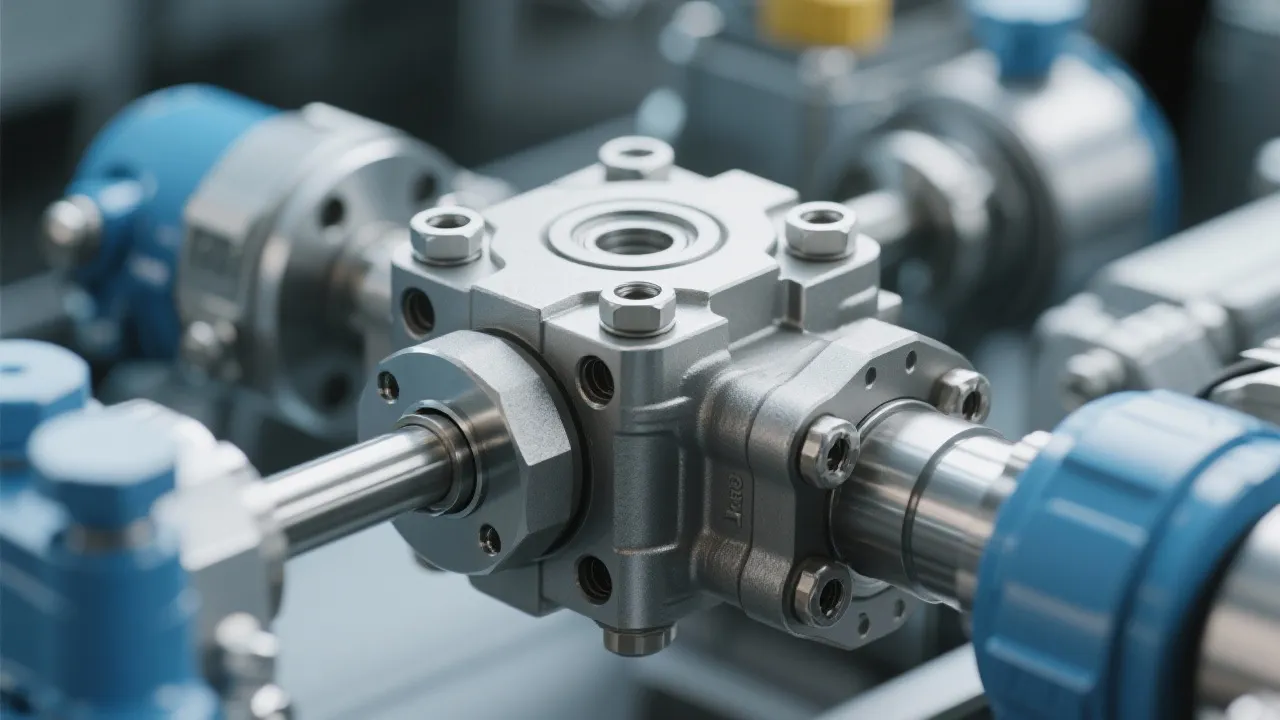

This guide explores the intricacies of Rexroth Servo Valves, crucial components in hydraulic systems renowned for precision control and reliability. Known in industries from manufacturing to aerospace, these valves ensure efficient energy use and accurate operation. Their complexity demands a deep understanding for effective application and maintenance.

Rexroth Servo Valves are pivotal components in many industrial sectors that require precise control of hydraulic power. Known for their engineering excellence and reliability, these valves are manufactured to deliver precision control in hydraulic systems, which is essential in industries ranging from aerospace to automotive manufacturing. This article provides an in-depth examination of Rexroth Servo Valves, delving into their functions, applications, and the unique benefits they offer to various manufacturing processes.

Servo valves, in general, are used to control the flow and pressure of liquids in hydraulic circuits. They convert low power electrical signals into high power flow, providing critical control in many mechanical systems. Rexroth Servo Valves, specifically, stand out in the industry for their durability and precision. These characteristics are particularly essential in applications where even minor errors can lead to significant issues.

Servo valves are generally categorized into different types based on their operation principles, such as Direct Operated, Pilot Operated, and Proportional Valves. Each type fulfills distinct requirements in industrial applications, enhancing the capability of fluid power systems by ensuring the correct flow rates and pressures are maintained based on system demands.

| Valve Type | Description |

|---|---|

| Direct Operated | Uses an electric signal to control the spool directly, ideal for low-flow applications. |

| Pilot Operated | Employs a pilot valve to control a larger main valve, suitable for high-flow applications. |

| Proportional Valve | Offers variable control of flow and pressure, allowing for more precise operations. |

The application of Rexroth Servo Valves is expansive. Industries such as aerospace, automotive, and heavy machinery rely heavily on the control and precision these components offer. In aerospace, they ensure the intricate maneuvers of aircraft systems are executed with high fidelity. For instance, they are employed in flight control systems where precise movements of actuators are required to maintain stability and control of the aircraft during various flight maneuvers. This precision is crucial in maintaining safety and reliability in aircraft operations.

In automotive manufacturing, Rexroth Servo Valves provide the exact force and speed necessary for operations such as stamping, molding, and assembly. Their precise control allows for better consistency in production, reducing waste and improving the overall quality of automotive components. For example, during the stamping process, the precise control of hydraulic cylinders powered by Rexroth Servo Valves ensures that each stamp is executed with equal force and speed, which is essential for high-quality part production.

Additionally, the role of Rexroth Servo Valves is critical in heavy machinery operations where precision and reliability can directly impact production efficiency and safety standards. In construction equipment, for example, the accurate control of hydraulic systems is vital for the effective operation of excavators, bulldozers, and cranes. The capability of Rexroth Servo Valves to adjust the flow rate and pressure swiftly enhances the response time of machinery, leading to improved operational performance.

While Rexroth Servo Valves offer numerous benefits, their integration and maintenance can pose challenges. Proper installation and regular maintenance are crucial to ensure good performance. Teams must be adequately trained to handle the complexities of these valves, including troubleshooting common issues that may arise during operation. Without proper knowledge and skills, users may encounter problems that could lead to inefficiencies or unexpected downtimes.

In addition, understanding the compatibility of differing valve types with specific applications is essential to maximize performance and minimize potential downtime. For example, selecting the appropriate valve type according to the flow rate and pressure requirements of a particular hydraulic circuit is critical for optimal performance. Insufficient or inappropriate selection can result in process inefficiencies, increased wear on hydraulic components, and potential system failures. Therefore, investing in training and system analysis is paramount for facilities utilizing Rexroth Servo Valves.

As industries evolve, so do the technological innovations surrounding servo valves. Rexroth has been at the forefront of integrating cutting-edge technology into their servo valve designs. One significant advancement is the use of electronic control systems which allow for real-time adjustments based on system feedback. This innovation enhances the precision and responsiveness of hydraulic systems, making them more adaptable to variable operational demands.

Furthermore, modern Rexroth Servo Valves are often equipped with digital communication interfaces, allowing for seamless integration with automation systems and digital control platforms. This connectivity facilitates advanced monitoring and control strategies, enabling predictive maintenance and improvements in system diagnostics. As a result, operators can quickly identify potential issues and make timely interventions, minimizing the risk of unexpected failures and extending the lifespan of hydraulic components.

Additionally, advancements in materials science have enhanced the performance and longevity of Rexroth Servo Valves. With the introduction of innovative materials that are resistant to wear and corrosion, these valves are now more reliable in harsh environments. This has opened up new application horizons in sectors where extreme conditions might have previously limited valve performance.

As the push for greater efficiency and sustainability continues across industries, Rexroth Servo Valves are positioned to play an even more significant role in the future of hydraulic systems. The trends of Industry 4.0, characterized by increased automation and data exchange in manufacturing technologies, will further integrate servo valves into smart factory concepts.

One trend poised to influence the future of Rexroth Servo Valves is the increasing demand for energy-efficient systems. With global initiatives focused on sustainability, there is a growing emphasis on technologies that reduce energy consumption and environmental impact. Rexroth Servo Valves contribute to this by allowing for fine-tuned control of hydraulic systems, thereby minimizing waste and enhancing energy efficiency.

Moreover, we can expect to see continued advancements in data analytics and artificial intelligence (AI) being applied to the operation of servo valves. This integration will facilitate smarter decision-making processes in hydraulic system management, enabling real-time adjustments based on predictive modeling and performance analysis. Such innovations can lead to more intelligent systems that optimize not only performance but also maintenance strategies.

Understanding the intricacies of Rexroth Servo Valves is critical for industries that demand high precision and reliability in their operations. These valves not only provide essential control but also greatly contribute to the efficiency and dependability of modern hydraulic systems. As technology progresses, the importance of components like Rexroth Servo Valves in optimizing industrial processes will continue to grow, solidifying their place as indispensable tools in a wide array of applications.

Investing in high-quality servo valves like those offered by Rexroth is essential for ensuring the successful operation of complex machinery and systems. As industries march forward into a more automated and interconnected future, the role of precision control technologies will only become more pronounced, emphasizing the need for superior control components that can meet and exceed modern operational requirements.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!