This article delves into the intricacies of proportional valves, crucial components in fluid control systems that regulate flow and pressure with precision. Proportional valves are widely used in hydraulic and pneumatic systems across industries, offering enhanced control, efficiency, and adaptability in various applications. Understanding their function, types, and benefits highlights their significance in modern industrial automation and machinery.

Proportional valves play a pivotal role in modern industrial systems, acting as the heart of hydraulic and pneumatic circuits. These versatile devices are engineered to control flow and pressure proportionally, offering smooth operation and precision control crucial in numerous applications. From manufacturing to automation, these components ensure optimal performance and efficiency. In an era where precision and efficiency are required, proportional valves have emerged as vital assets in the design and implementation of automated systems. Because of their versatility, they can be tailored for specific needs across varied sectors. This introduction sets the stage for a deeper examination of their designs, functions, and adaptations to a rapidly changing technological landscape.

Proportional valves stand out due to their ability to deliver variable output, essential for fine-tuning processes that demand precise adjustments. Unlike conventional on-off valves, proportional valves adjust the flow according to input signals, allowing for seamless transitions and enhanced control. Their ability to provide variable control enhances efficiency, reduces energy consumption, and prolongs equipment life, making them indispensable in complex systems. The flexibility offered by proportional valves allows operators to customize flow rates and pressure levels, adapting the system’s performance to match real-time requirements. Moreover, their application contributes to the safety and reliability of industrial processes by ensuring consistent operation under varying conditions.

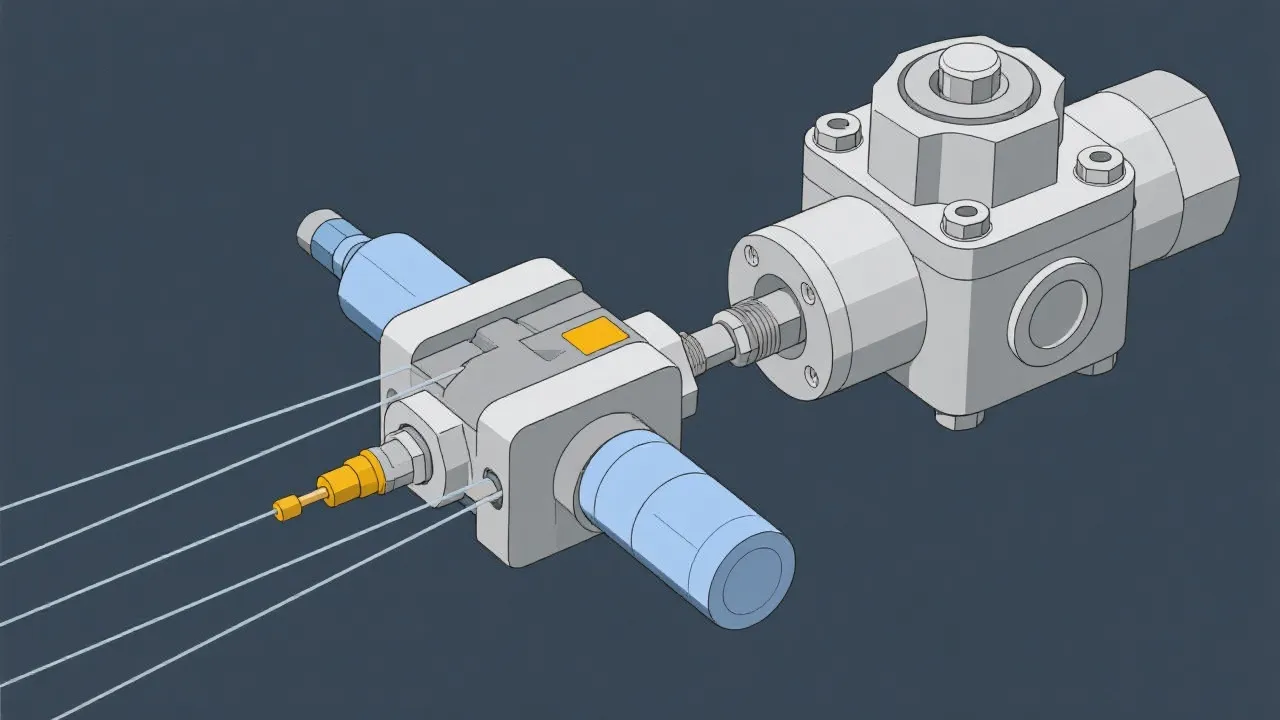

The working principle of a proportional valve revolves around converting electrical signals into mechanical movements that regulate fluid flow and pressure. Core components typically include a spool or poppet, an actuator, and a feedback mechanism. The actuator, often electromagnetic or hydraulic, positions the valve spool to precisely open or close the flow path, based on varying input control signals. In this setup, the electrical inputs can be analog or digital, allowing for different levels of precision. For instance, analog signals provide a continuous range of control, while digital signals often incorporate feedback loops that improve responsiveness. This mechanism ensures that any changes in an application can be swiftly and accurately addressed.

Proportional valves come in a variety of types, tailored to meet diverse industrial needs:

Proportional valves are integral to various industries, including:

The implementation of proportional valves offers several advantages:

Advancements in proportional valve technology include digital integration and smart systems, paving the way for improved diagnostics, remote operation, and automated maintenance alerts. Such innovations promise to revolutionize fluid control systems, offering even greater efficiency and adaptability in the future. Emerging technologies like the Internet of Things (IoT) allow for real-time monitoring and control of proportional valves, enabling predictive maintenance and reducing downtime. Furthermore, as industries push for greater automation, proportional valves will likely evolve to integrate with advanced AI and machine learning algorithms, providing more intelligent and responsive control mechanisms. The future of proportional valves is not only about enhancing performance but also about making systems more resilient and adaptable to changing operational demands.

| Type | Function |

|---|---|

| Directional Control Valve | Directs fluid to specific paths, controlling equipment movements. |

| Pressure Control Valve | Maintains desired pressure levels, ensuring system stability. |

| Flow Control Valve | Regulates fluid flow rate for precise speed control. |

In conclusion, proportional valves are key components that drive efficiency and precision in industrial operations. Their ability to adapt to diverse applications highlights their critical role in modern manufacturing and automation sectors. Understanding their functionalities not only enhances system effectiveness but also opens avenues for innovation and technological breakthroughs. As industries continue to evolve, so too will the capabilities and applications of proportional valves, solidifying their place as indispensable tools in achieving advanced operational excellence and sustainability in the future.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!