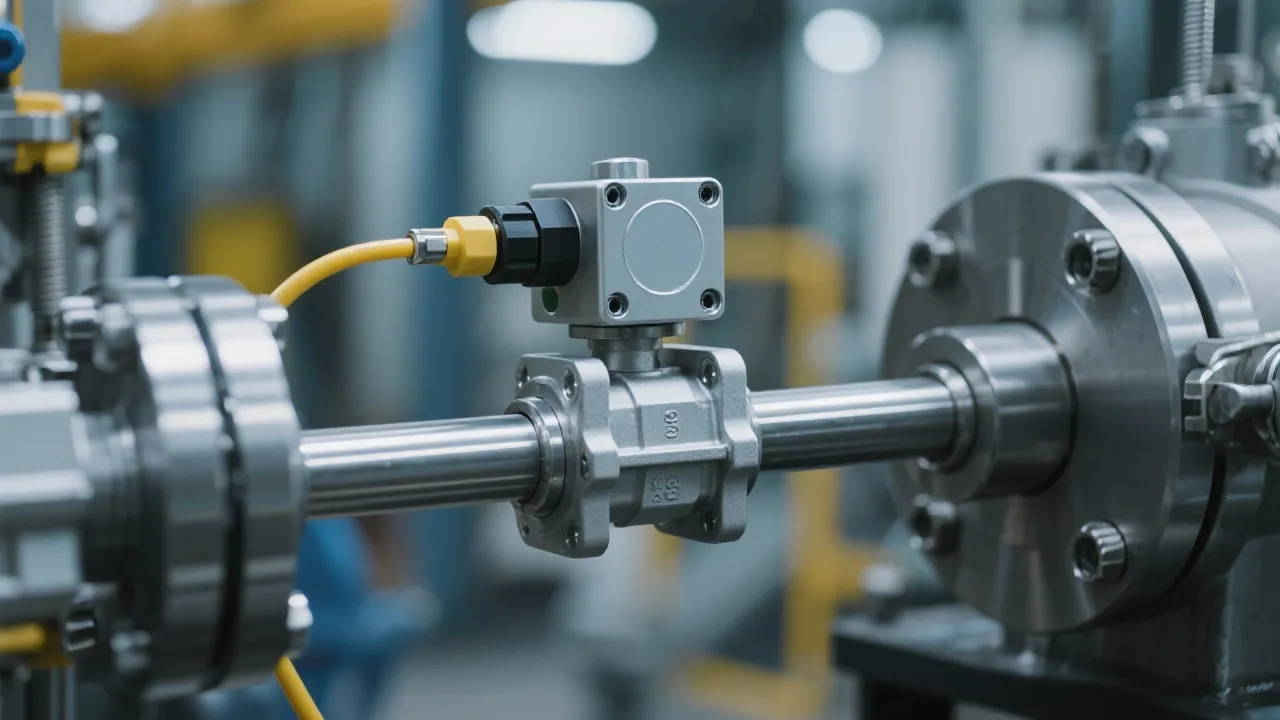

This guide delves into the intricate world of Rexroth Servo Valves, highlighting their applications and technological advancements. Rexroth Servo Valves are crucial in various industries, offering precise control of hydraulic fluid. Their design and functionality cater to efficiency and accuracy, making them indispensable in automation and heavy machinery.

Servo valves play an instrumental role in the control and automation of hydraulic systems. Among the prominent players in the hydraulic valve industry, Rexroth stands out with its innovative servo valve solutions. Rexroth Servo Valves are renowned for their precision and efficiency in diverse applications, ranging from automotive manufacturing lines to aerospace technologies. As industries become increasingly automated and technologically advanced, the demand for reliable servo valves has grown, making Rexroth a trusted name among engineers and operators looking for robust solutions.

Rexroth Servo Valves utilize advanced technology to manipulate hydraulic fluid control with extreme accuracy. These valves operate by responding to electronic signals that adjust the position of a spool, regulating fluid flow and pressure. This precision allows for smooth and accurate machine operations, which is critical in industries where precision machinery is involved. The electronic feedback systems integrated into Rexroth Servo Valves further enhance their performance by allowing real-time adjustments based on the operating conditions, ensuring that desired output levels are maintained consistently.

The technological sophistication of these servo valves includes features like proportional control, where the output flow is proportional to the input signal, and pulse width modulation (PWM), which regulates power delivery. Additionally, Rexroth Servo Valves are equipped with advanced sensors and microprocessors that monitor performance metrics and provide diagnostics, which aid in predictive maintenance and system optimization.

Industries such as automotive, aerospace, and manufacturing heavily rely on Rexroth Servo Valves for their ability to handle complex fluid dynamics with precision. In automotive assembly lines, these valves ensure the accurate movement of robotic arms, which are vital for tasks like welding, painting, and assembly. The consistent performance of Rexroth Servo Valves helps optimize production rates and maintain product quality, thereby reducing operational costs.

In aerospace applications, these valves play a pivotal role in the control of flight surfaces, landing gear, and engine throttles, where minimal response times and reliable performance are non-negotiable. Furthermore, Rexroth Servo Valves are employed in industrial automation settings where coordinated control of multiple axes is required for processes such as material handling and processing. The versatility of Rexroth Servo Valves extends to any application requiring high-response hydraulic controls, including injection molding machines, CNC machines, and robotics.

The primary benefits of using Rexroth Servo Valves include improved efficiency, enhanced control precision, and reduced downtime. Their robust design ensures longevity, even under strenuous operational conditions. Operators can expect a high degree of control over hydraulic systems, which translates to better energy efficiency and reduced wear and tear on equipment.

Additionally, the seamless integration with existing systems helps minimize transition time, thus optimizing operational workflows. Engineers and machine operators can implement Rexroth Servo Valves without needing extensive modifications to their current systems, leading to significant cost savings in both installation and maintenance. The use of modular designs in Rexroth components also allows for easier upgrades and replacements, adding to the overall cost-effectiveness of these solutions.

Another precious advantage is the availability of comprehensive support services from Rexroth, including training, installation assistance, and after-sales service. This ensures that users can maximize the performance of their servo valve systems and respond promptly to any challenges that arise during operation.

| Feature | Rexroth Servo Valves | Competitor A | Competitor B |

|---|---|---|---|

| Control Precision | High | Medium | Medium-High |

| Durability | Long-lasting | Moderate | Long-lasting |

| Integration Ease | Seamless | Complex | Moderate |

| Maintenance Requirements | Low | High | Medium |

| Response Time | Fast | Moderate | Fast |

| Customization Options | Extensive | Limited | Moderate |

This comparative analysis highlights why Rexroth Servo Valves often emerge as the preferred choice in high-demand environments. The superior control precision and durability, coupled with low maintenance requirements and extensive customization options, grant them an edge over competitors. As industries progressively lean towards smart and efficient manufacturing processes, Rexroth’s dedication to innovation positions them as a leader in this space.

Selecting the appropriate Rexroth Servo Valve depends on several factors such as application requirements, system specifications, and budget considerations. Experts recommend consulting with certified suppliers for tailored advice and to ensure that the chosen servo valves meet all operational demands. It is also beneficial to conduct a thorough assessment of your hydraulic system, including flow and pressure specifications, as well as response times needed for effective control.

Furthermore, understanding the environment in which the servo valve will operate is crucial. Factors such as temperature extremes, potential exposure to contaminants, and physical space limitations can significantly influence the choice of valve. Operators should also consider future scalability and whether the system may require additional valves or capabilities as production demands evolve.

When deciding between various models, it’s important to review technical specifications, consult with system designers, and investigate case studies from similar applications. Often, manufacturers like Rexroth provide extensive resources, including technical documentation and customer support, to guide customers in choosing the best product tailored to their unique needs.

As industries evolve, so too does the technology surrounding servo valves. The rise of Industry 4.0, characterized by automation, data exchange, and smart technology integration, is influencing the development of servo valves. Upcoming trends include the incorporation of smart sensors and IoT connectivity, enabling real-time monitoring and control operations from remote locations or central command hubs. This capability allows for increased operational efficiency, real-time performance analysis, and enhanced predictive maintenance strategies.

Furthermore, advancements in materials science are leading to the production of lighter, more durable components that can withstand harsh conditions while providing a high degree of precision. This trend is essential for applications in sectors like aerospace, where every ounce of weight savings translates into improved performance and fuel efficiency.

Rexroth is actively participating in this shift, consistently investing in research and development to expand its product offerings. Future servo valve models are likely to feature improved energy efficiency metrics, reduced environmental impact through energy-saving technologies, and enhanced interface solutions to work seamlessly with existing automation systems.

In conclusion, Rexroth Servo Valves represent a vital component in industries where precision and control are paramount. Understanding their functionality, applications, and advantages can significantly impact operational efficiency and machinery longevity. As this technology continues to advance, staying informed about innovations in servo valve design and capabilities will be crucial for industries looking to maintain a competitive edge.

Ultimately, the strategic incorporation of Rexroth Servo Valves into hydraulic systems not only boosts efficiency but also enhances robustness and reliability, thus paving the way for a more automated, responsive, and productive manufacturing landscape.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!