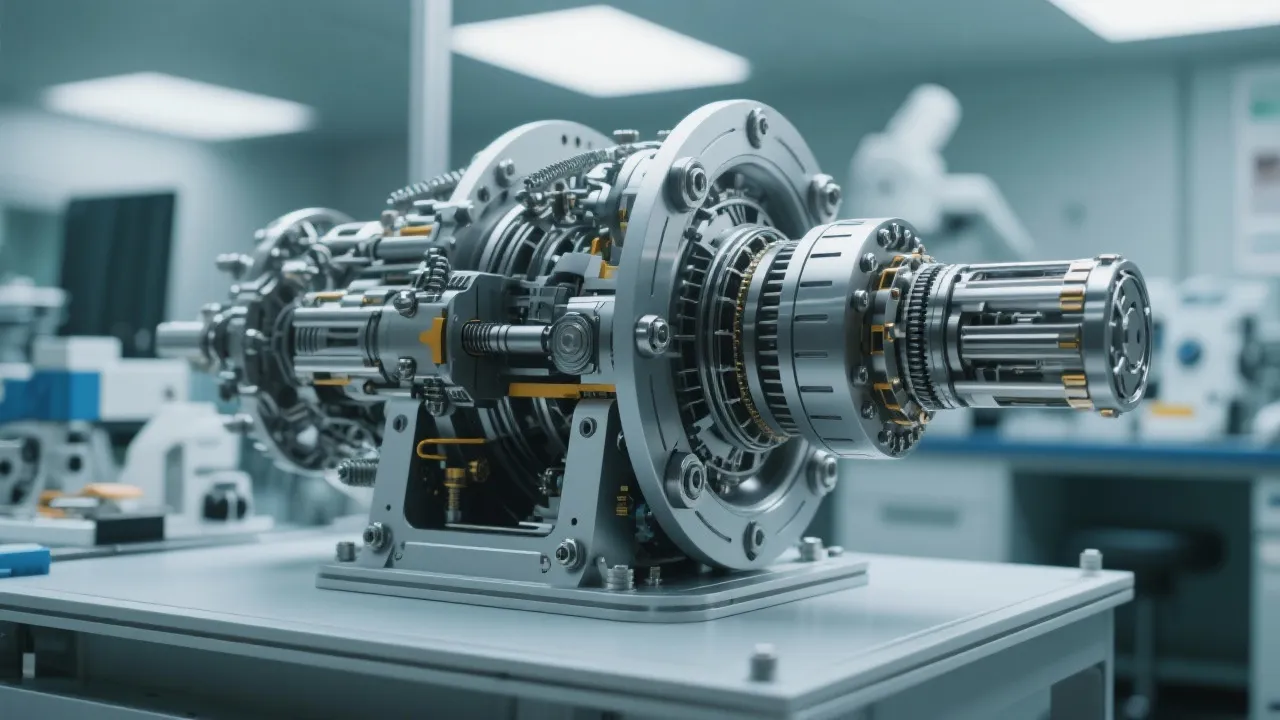

Lvdt Proportional Valves play a pivotal role in modern control systems by converting electrical signals to precise mechanical actions, enhancing system efficiency. These valves use an LVDT (Linear Variable Differential Transformer) for feedback control, ensuring optimal performance in a variety of industries. Learn how these components contribute to automation, efficiency, and precision in industrial applications.

In today's advanced industrial landscape, the mastery of control systems is crucial for achieving precise operations, efficiency, and automation. Proportional control systems are integral to modern engineering, where the LVDT Proportional Valve stands out due to its significant contribution to system precision. This article delves into the complexities of LVDT Proportional Valves, elucidating their function, benefits, and applications in contemporary industry.

The LVDT Proportional Valve is a critical component in control systems, utilizing a Linear Variable Differential Transformer (LVDT) for position feedback. These valves convert electrical input signals into a mechanical output, allowing for meticulous control over fluid flow. The LVDT's role is to provide accurate positional feedback to the valve control system, ensuring precise adjustments and maintaining system stability. The precise functioning of LVDT valves is essential in scenarios where minute variations in flow control can lead to significant impacts on system performance or output quality.

At the heart of an LVDT Proportional Valve is the LVDT sensor, known for its exceptional reliability and accuracy. This sensor consists of a primary coil and two secondary coils. When connected to an excitation voltage, the primary coil generates an electromagnetic field. The ferromagnetic core's position relative to these coils causes variations in the induced voltages across the secondary coils, delivering a differential output signal that directly correlates with the core's position. This principle of operation not only underpins the sensing capability of the valve but also serves as a foundation for precise adjustments in a myriad of applications.

The LVDT's design is inherently non-contact, meaning there is no physical contact between the moving core and the coils. This lack of friction results in negligible wear over time, enhancing the sensor's lifespan and reliability. Moreover, the use of LVDT technology ensures that even the smallest movements are accurately detected and translated into actionable control signals.

LVDT Proportional Valves are utilized across various industries due to their precision and adaptability. Their ability to operate in demanding environments makes them ideal for a wide array of applications:

Adopting LVDT Proportional Valves in industrial applications offers numerous advantages. The following factors contribute to their widespread use in various sectors:

| Aspect | LVDT Proportional Valves | Conventional Valves |

|---|---|---|

| Precision | High due to feedback control | Moderate, depending on manual adjustments |

| Response Time | Fast | Slower due to manual control |

| Maintenance | Low, minimal wear | Higher, more prone to mechanical issues |

| Cost Efficiency | Good savings in precision tasks | Potentially high due to frequent maintenance |

This table summarizes critical aspects of LVDT Proportional Valves compared to conventional valve systems, highlighting their superior performance metrics. Such comparisons enable engineers and decision-makers to better understand the value proposition of integrating modern control technologies into their systems.

While LVDT Proportional Valves offer numerous benefits, organizations considering their implementation should also be aware of potential challenges. Understanding these pitfalls can aid in making informed decisions and ensures smoother integration into existing processes.

The landscape of industrial control systems continues to evolve, heavily influenced by advancements in automation technology, data analytics, and smart manufacturing. As these trends shape the future of various industries, the role of LVDT Proportional Valves is expected to grow significantly. These valves are increasingly vital for systems that rely on real-time data and automated responses to changing conditions.

Adaptations in LVDT technology incorporate enhanced digital signal processing and connectivity that supports smart systems, allowing for improved integration with Industry 4.0 applications. This adaptability ensures that LVDT Proportional Valves remain relevant and beneficial, aligning with the scalable needs of modern infrastructures.

Furthermore, with the expanding emphasis on sustainability and energy efficiency, LVDT valves are likely to gain traction through their ability to optimize processes and minimize waste in various industrial operations. As production processes become more intricate, the precision offered by these systems will be essential to maintaining a competitive edge.

LVDT Proportional Valves are indispensable in the world of modern industrial control systems, offering unmatched precision, reliability, flexibility, and efficiency. As industries continue to evolve, and the demand for automation and exact control increases, the role of LVDT technology in enhancing valve performance becomes ever more critical. Consequently, the adoption of LVDT Proportional Valves is not just advantageous but essential for future-ready, competitive industries. As organizations look towards the future, integrating LVDT technology into their operations will provide them with the tools necessary to achieve success in a rapidly changing industrial environment.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!