Proportional valves are integral to the automation and fluid control industries, offering more precise control of fluid flow compared to traditional valves. These devices regulate flow and pressure in diverse applications, from manufacturing to aerospace. In exploring proportional valves, one appreciates their role in enhancing efficiency in various mechanical systems.

Proportional valves are pivotal components in the world of fluid dynamics, known for their ability to modulate flow or pressure with high precision. Unlike conventional on/off solenoids, proportional valves provide a more gradual and controlled action, making them ideal for applications requiring fine adjustments. Their versatility allows them to be used in various sectors, from manufacturing to automotive, ensuring that systems can operate efficiently while responding to dynamic inputs. In today’s rapidly evolving technological landscape, the demand for such precise control mechanisms will only continue to grow, underscoring the importance of understanding proportional valves.

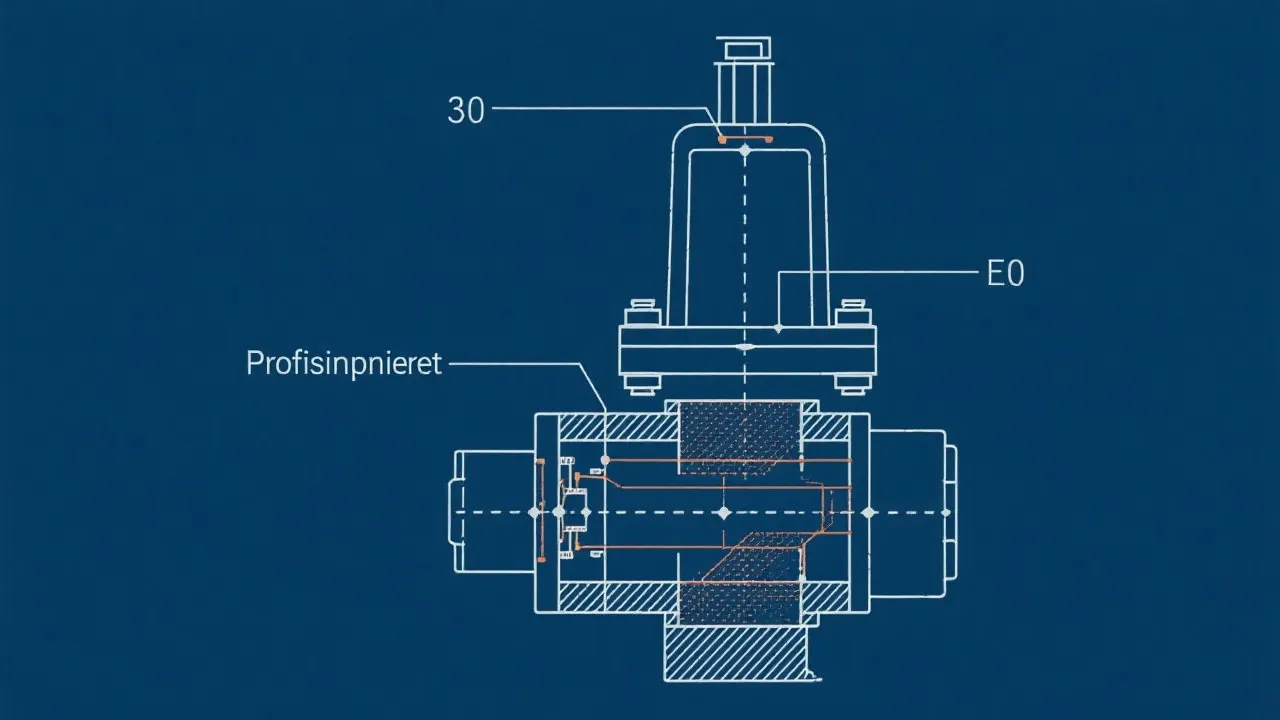

The design of a proportional valve primarily revolves around its electromagnetically controlled components. One of its key features is an electromagnet whose current can be varied, thus adjusting the valve’s opening. This precision design enables proportional valves to operate effectively in environments where specific flow rates are crucial. A typical proportional valve consists of several core components, including a valve body, a spool, and a feedback mechanism that determines the position of the spool based on the demand for flow or pressure.

Moreover, many modern proportional valves include built-in features that enhance their functionality. For example, materials with higher temperature and corrosion resistance are increasingly used to ensure durability in challenging operating environments. These innovations lead to a more resilient design that can withstand the daily rigors of industrial use without sacrificing performance. Additionally, the incorporation of advanced sensors allows for real-time monitoring of fluid parameters, further optimizing system performance.

Proportional valves operate by varying the current supplied to the electromagnet, which directly influences the position of the valve spool. In this mechanism, as more current is applied, the valve opens further, allowing a greater flow. The working principle is often described as a “closed-loop system.” A feedback loop monitors the actual output flow or pressure and communicates this information back to the control system, allowing for fine-tuning of the electromagnet’s current. This dynamic adjustment is a key feature that allows proportional valves to excel in precise control applications.

The interaction between hydraulic pressure and the lift of the spool is fundamental to how proportional valves maintain stable operation under varying conditions. For instance, during sudden changes in demand – like starting or stopping an actuator – the valve can quickly respond, adjusting the flow to maintain system pressure and optimize performance. This is why proportional valves are favored in high-precision operations, such as robotics and automated manufacturing lines, where any deviation in pressure or flow could lead to severe operational inefficiencies.

In industries such as automotive manufacturing, aerospace, and material handling, proportional valves play a central role in fluid management systems. In automotive systems, for example, they help control the hydraulics of various machinery, ensuring smooth operation of brakes and suspension systems. Without these valves, it would be impossible to achieve the level of responsiveness required for modern vehicles, which often rely on fine control for safety and performance.

In aerospace, proportional valves maintain the precise control necessary in flight control systems, where even minute variations can lead to significant performance implications. The role of these valves extends to managing thrust vectoring and cabin pressurization, among other critical functions, highlighting their importance in ensuring safe and efficient operations. In the realm of material handling, including conveyor systems and automated guided vehicles (AGVs), proportional valves facilitate precise control of hydraulic actuators, enabling them to operate smoothly and efficiently under varying load conditions.

The burgeoning field of robotics also leverages proportional valve technology, where they are used to control hydraulic and pneumatic actuators. This allows robots to perform delicate maneuvers and tasks that require high precision. As industries continue to explore automation further, the demand and application range for proportional valves are likely to expand dramatically.

While traditional valves (such as on/off valves) are reliable components in many systems, their limitations become apparent in scenarios requiring nuanced control of flow. Proportional valves offer several significant advantages:

Each of these advantages has broader implications for overall system design and operation, encouraging industries to pivot towards incorporating proportional valve technology in legacy systems. As the manufacturing landscape evolves and emphasizes automation and control, the role of proportional valves will continue to be critically important.

| Proportional Valve Type | Application | Key Benefit |

|---|---|---|

| Analog Proportional Valves | Fluid power systems | Fine flow control |

| Digital Proportional Valves | Automated systems | Precision and integration |

| Hydraulic Proportional Valves | Construction machinery | Robust pressure control |

| Pneumatic Proportional Valves | Packaging machinery | Quick actuator response |

| Servo Proportional Valves | Robotic applications | High precision and repeatability |

The diversity of applications indicates that the technology behind proportional valves can be adapted to meet various industrial requirements. Each type of valve is engineered to maximize performance in specific applications, catering to the unique needs of different operational environments.

Despite their numerous advantages, users must consider several challenges when integrating proportional valves into their systems. One key consideration is the integration costs, which can be substantial, especially for organizations transitioning from traditional systems to more sophisticated proportional systems. Additionally, there is a necessity for skilled technicians to maintain and calibrate these advanced systems. Without proper training and expertise, organizations may struggle to extract the full benefits offered by proportional valves.

Choosing the correct type and size of valve is critical as well; an inappropriate choice could negate the anticipated benefits. For instance, a valve that is too large may lead to unnecessary energy consumption, while one that is too small may not meet the system requirements. This underscores the importance of consulting with experts or suppliers to ensure optimal selection based on specific application needs.

Furthermore, users should also consider the maintenance schedule for proportional valves, as consistent upkeep is necessary to maintain optimal performance and prevent unexpected failures. Implementing predictive maintenance strategies, aided by technological advancements such as IoT connectivity, can help in monitoring valve performance and identifying issues before they escalate.

Recent advances in the field of proportional valve technology include the development of smart proportional valves that come equipped with sensors and connectivity features. These innovations allow for real-time monitoring and adjustments through IoT systems, enabling more responsive and efficient operations. This move toward smart technology is transforming traditional industries into smart operations that can adapt quickly to changing conditions.

Additionally, the integration of artificial intelligence (AI) in controlling proportional valves enhances their efficiency further. AI algorithms analyze data from multiple sources to predict future demands and adjust valve settings proactively, fostering even more efficient operations and reducing the potential for waste.

Moreover, designers are increasingly focusing on miniaturizing proportional valve components without sacrificing reliability or performance. This trend is particularly beneficial in applications requiring compact designs, such as robotics or medical devices, where space is at a premium. The continued innovation in valve technology exemplifies the field's progress and the findings from ongoing research and development efforts.

In conclusion, as industries increasingly prioritize efficiency and precision, proportional valves stand out as crucial components in modern automation systems. Their advanced design allows for high levels of control in fluid dynamics, enhancing operational efficiency across various sectors. By understanding their design, applications, innovations, and challenges, organizations can leverage proportional valves to improve their systems significantly, ensuring reliability and performance in an ever-evolving industrial landscape.

As we look ahead, the landscape of proportional valve technology is poised for continued evolution. The integration of digital technologies and smart features indicates a shift towards more efficient and responsive systems. Industries are moving towards greater automation and data-driven operations, necessitating control mechanisms that can keep pace with these advancements.

Emerging trends such as hybrid applications, where hydraulic and electric components coexist, are becoming more feasible due to technological advances in proportional valve design. This shift allows for even more versatility in applications, from robotics to advanced manufacturing systems, providing the ability to rapidly adapt to changing operational needs while maintaining energy efficiency.

Additionally, the use of advanced materials and manufacturing techniques, such as 3D printing and composite materials, is likely to enhance the versatility and durability of proportional valves. These innovations can lead to lighter yet stronger components that perform reliably in various conditions. The emphasis on sustainable practices in industrial operations may also push for the development and use of environmentally friendly materials in valve construction.

Moreover, with regulatory pressures to reduce energy consumption and emissions, proportional valves are expected to play a vital role in enabling compliance. Their efficiency can contribute significantly to reducing the overall carbon footprint of industrial processes, making them appealing not only from a performance standpoint but also from an environmental perspective.

In closing, the significance of proportional valves in modern industry cannot be overstated. As fundamental components within fluid control systems, they offer unmatched versatility, efficiency, and performance. Understanding their function, advantages, design innovations, and challenges is essential for anyone involved in industrial operations or engineering. By investing in the right proportional valves and technologies, organizations can ensure that they remain at the forefront of efficiency and reliability in today's competitive landscape.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!