Proportional valves are crucial components in modern automation processes, allowing precise control of fluid flow by modulating valve positions. These valves are extensively utilized across industries such as manufacturing, automotive, and aerospace, gradually replacing conventional on/off valves due to their efficiency and adaptability. Their integration into various systems underscores their importance in enhancing operational performance and energy efficiency.

Proportional valves are innovative components widely used in various industries for precisely controlling the flow and pressure of fluids. Unlike traditional on/off valves, which operate in a binary mode, proportional valves can adjust their output gradually and continuously. This capability makes them indispensable in applications that require nuanced fluid management, such as in hydraulic systems, pneumatic systems, and many automation processes. The operation of proportional valves ensures enhanced efficiency, accuracy, and energy conservation within complex systems, reflecting modern demands for precision engineering and sustainability.

Proportional valves have become essential in industries where precision and reliability are paramount. In the manufacturing sector, these valves play a critical role in automated production lines, where they regulate hydraulic or pneumatic circuits to optimize both speed and force. For instance, during the assembly of vehicles, proportional valves can control the pressure and flow of hydraulic systems that operate robotic arms, thus ensuring the accurate positioning and assembly of parts without damaging sensitive components.

Additionally, in the automotive industry, proportional valves are employed in fuel injection systems, enhancing engine performance. They ensure the optimal mixture of air and fuel in combustion engines which leads to better fuel efficiency and reduced emissions. Modern cars increasingly rely on advanced proportional valves to meet stringent environmental standards and adapt to real-time driving conditions.

Aerospace engineering also benefits significantly from the meticulous control offered by proportional valves. For instance, in aircraft systems, these valves manage hydraulic actuators responsible for moving wing flaps, landing gear, and other crucial components, thereby contributing to the vehicle's navigational accuracy and fuel efficiency at various flight stages. The ability of proportional valves to modulate flow based on flight conditions enhances performance and safety. Other applications include chemical processing plants that depend on proportional valves for maintaining precise chemical concentrations, ensuring product quality and safety during production.

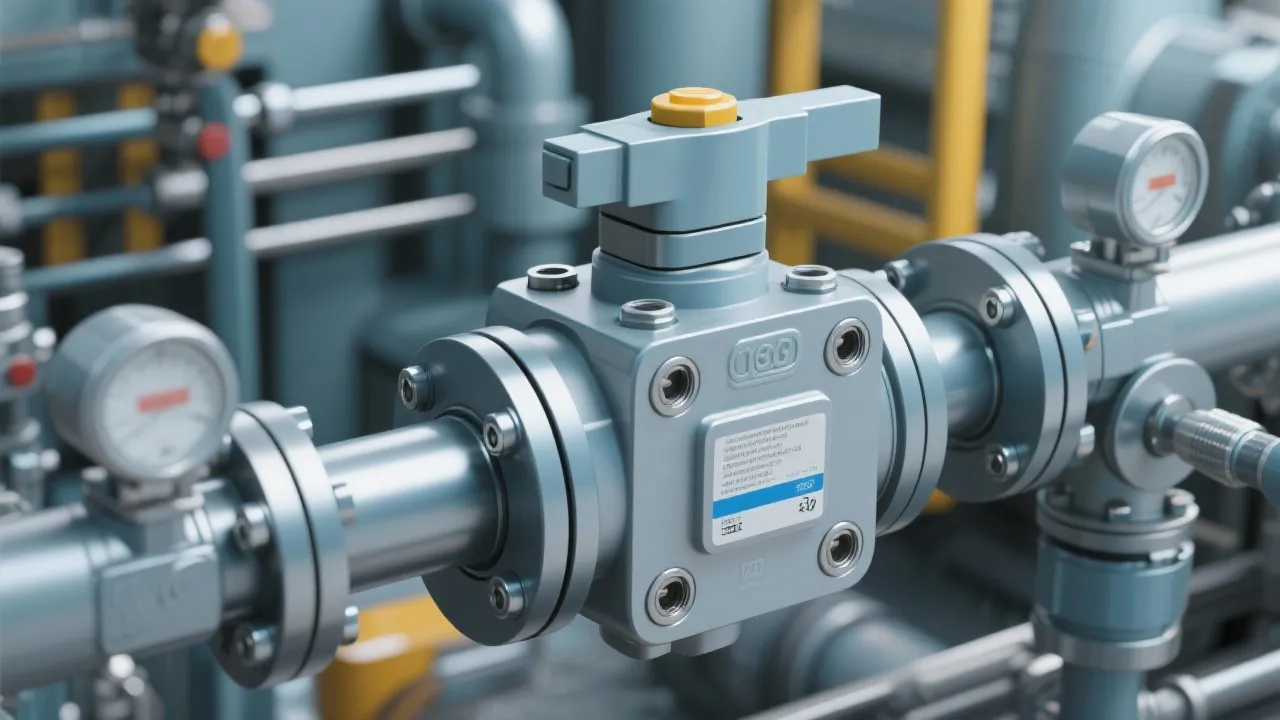

At the core of proportional valves' functionality is their ability to regulate fluid flow through varying valve positions. Unlike binary on/off valves, these devices utilize a combination of a solenoid coil and a spool mechanism to proportionally control the flow rate. The solenoid is an electromagnetic actuator that converts electrical energy into mechanical movement. When an electrical current passes through the solenoid, it creates a magnetic field that moves the spool within the valve body. This spool's position determines the size of the opening through which the fluid flows.

This gradient modulation is achieved by adjusting the electrical input to the solenoid, which in turn alters the position of the spool. For example, a higher voltage can be supplied to increase the flow rate while reducing the voltage corresponds to a decrease in flow. As the spool moves to different positions, the flow rate is finely tuned to meet specific operational demands, optimizing performance and minimizing waste, which supports sustainable practices across various industries. Additionally, the response time of proportional valves is crucial, as their rapid actuation allows for adjustments to be made in real-time, enhancing system responsiveness.

Proportional valves present numerous advantages over traditional valve types. One primary benefit is their ability to provide variable control. This is crucial in reducing energy consumption in fluid systems. Instead of operating at full capacity irrespective of the need, systems utilizing proportional valves can tailor output based on real-time demands, preventing unnecessary energy expenditure. This ability not only leads to cost savings but also contributes to reducing the environmental impact of operating machinery.

Another significant advantage is the precision of proportional valves, which minimizes the risk of mechanical shocks within hydraulic and pneumatic systems. By enabling smooth transitions between different flow rates, proportional valves protect other components of the system from damage caused by sudden pressure changes. This factor ultimately extends the lifecycle of the equipment and reduces maintenance costs.

Moreover, the integration of these valves within digital control systems enhances adaptability and scalability. Industries can easily modify system parameters without substantial hardware adjustments, thereby allowing them to rapidly respond to changing production demands or regulatory requirements. For instance, in a manufacturing setting, if production volume fluctuates, a proportional valve can immediately adjust to accommodate the change without the need for extensive system overhaul. This flexibility translates into both operational savings and competitive advantages in a constantly evolving market.

While proportional valves offer numerous benefits, their implementation is not without technical challenges. One of the key issues is the complexity of the control systems required to operate these valves. The need for precise electrical signals and feedback loops can introduce a level of sophistication that may be overwhelming for some businesses, especially those that are transitioning from traditional systems. However, this challenge can be addressed through proper training of personnel and investment in reliable control technology.

Another challenge arises from the potential for wear and tear on the mechanical components of proportional valves, particularly in high-cycle applications. Over time, the spool and seat can experience degradation, leading to performance issues such as leakage or sticking. To mitigate these risks, manufacturers often employ advanced materials for valve construction that offer greater resistance to wear. Regular maintenance and monitoring of valves can also help identify issues early, allowing for timely repairs or replacements, thereby ensuring continued precision and efficiency.

The primary purpose of a proportional valve is to allow precise control of fluid flow and pressure by modulating the valve position continuously. This contrasts with traditional valves, which can only either fully open or fully close the flow.

Unlike on/off valves that operate in binary states, proportional valves can adjust their output incrementally, allowing for more nuanced control of fluid systems. This capability is essential in applications where specific performance levels are critical.

Industries such as manufacturing, automotive, aerospace, and chemical processing benefit substantially from the efficiency and precision offered by proportional valves. In particular applications, their adaptability and reliability contribute to optimizing production processes, improving product quality, and enhancing overall system performance.

Automation has transformed various sectors by streamlining processes and increasing productivity. Proportional valves are crucial in modern automation frameworks, facilitating precise control over pneumatic and hydraulic systems. Their ability to provide variable control directly supports the objectives of automation by ensuring that machinery operates at optimal conditions based on real-time data.

In automated assembly lines, for example, proportional valves control the flow of pneumatic actuators that operate conveyor belts, robotic arms, and other machinery. The precise adjustment capabilities help not only in maintaining consistent speeds but also in managing intricate tasks that require variations in force and motion. Such detailed control directly impacts the quality of the output, enhancing overall productivity.

Additionally, in process automation within industries like food and beverage, pharmaceuticals, and chemicals, proportional valves provide the necessary control for the mixing and dispensing of materials. Their role in maintaining specified flow rates allows for the consistent quality of products and minimizes wastage. Furthermore, the integration of proportional valves within programmable logic controllers (PLCs) enhances operational efficiencies since changes in system parameters can be executed swiftly without manual intervention.

The technology surrounding proportional valves is continuously evolving, with several emerging trends shaping their functionality and application. One notable trend is the advancement toward full digitalization in control systems, where proportional valves are increasingly integrated with smart technologies. This development facilitates the implementation of condition monitoring and predictive maintenance practices.

By leveraging IoT (Internet of Things) technology, companies can gather and analyze data from valves in real-time to assess performance and maintenance needs. This data-driven approach not only enhances operational efficiency but also reduces downtime through timely interventions. Predictive algorithms can forecast when a valve might fail based on historical performance data, enabling businesses to take action before an unplanned outage occurs.

Another trend is the focus on eco-friendly designs and materials in proportional valves. As industries seek to meet stricter environmental regulations and drive sustainability, manufacturers are exploring materials that are less harmful to the environment and designs that reduce energy consumption. Innovations such as energy-efficient actuators and biodegradable components are gaining traction, emphasizing the need to balance performance with ecological responsibility.

In conclusion, proportional valves have revolutionized fluid control systems across numerous industries by providing enhanced accuracy, efficiency, and adaptability. Their role in enabling precise control has allowed companies to optimize operations, reduce waste, and improve product quality. As technological advancements continue, particularly in automation and smart technology integration, the application and importance of these valves are expected to grow further, underscoring their essential place in modern engineering solutions. In an era increasingly focused on sustainability and efficiency, proportional valves exemplify how innovative engineering can lead to significant improvements in performance and environmental responsibility.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!