This article delves into the significance of Rexroth Filters within various industrial settings. Rexroth, part of Bosch Rexroth, is renowned for producing high-quality hydraulic components crucial for machinery across industries, ensuring optimal performance and longevity. We explore the intricacies of these filters, their impact on machinery efficiency, and how they contribute to streamlined operations.

Rexroth Filters are integral components in hydraulic systems, ensuring the machinery's optimal performance by maintaining the purity of hydraulic fluids. Originating from Bosch Rexroth, a key player in motion control and industrial technology, these filters help safeguard against contaminants that can significantly degrade system efficiency and longevity. This analysis explores the roles, benefits, and applications of Rexroth Filters in various industrial settings, dissecting their functionality while also considering the latest advancements in filter technology.

In hydraulic systems, cleanliness is paramount. Contaminants such as dirt, metal particles, and residues from wear can drastically reduce the lifespan of machinery components. By effectively filtering out these impurities, Rexroth Filters help improve the reliability and efficiency of hydraulic systems. This ultimately leads to reduced maintenance costs and higher system availability.

Hydraulic fluids are vital for the efficient transmission of power within hydraulic machinery. Contamination can cause cavitation, increased wear, and can even lead to catastrophic failures. Studies have shown that a significant percentage of hydraulic failures can be attributed to contamination, underscoring the need for high-quality filtration systems. In fact, a clean hydraulic system can frequently operate at full capacity, providing consistent and reliable performance throughout its lifecycle.

Rexroth Filters find applications across numerous industries, including manufacturing, construction, and aerospace. In manufacturing, these filters are critical in maintaining the efficiency of automated assembly lines where precision and reliability are indispensable. For instance, robots on assembly lines, often powered by hydraulic systems, depend on clean fluids to ensure operational accuracy.

In construction machinery, such as excavators and loaders, Rexroth Filters ensure the hydraulic systems operate smoothly, reducing the risk of breakdowns. For example, during excavation projects, hydraulic systems control the movement of the boom and bucket, where contaminants can disrupt movement and lead to inefficiencies. Furthermore, in the aerospace sector, the reliability and precision of Rexroth Filters contribute to the safe operation of aircraft hydraulic systems, responsible for critical functions including landing gear operations and flight control surfaces.

Moreover, the agricultural sector has adopted Rexroth Filters in modern farming equipment, where hydraulic systems control various operations such as plowing, planting, and harvesting. Keeping these hydraulic systems clean means minimizing downtime on farms, which is crucial during busy planting and harvest seasons.

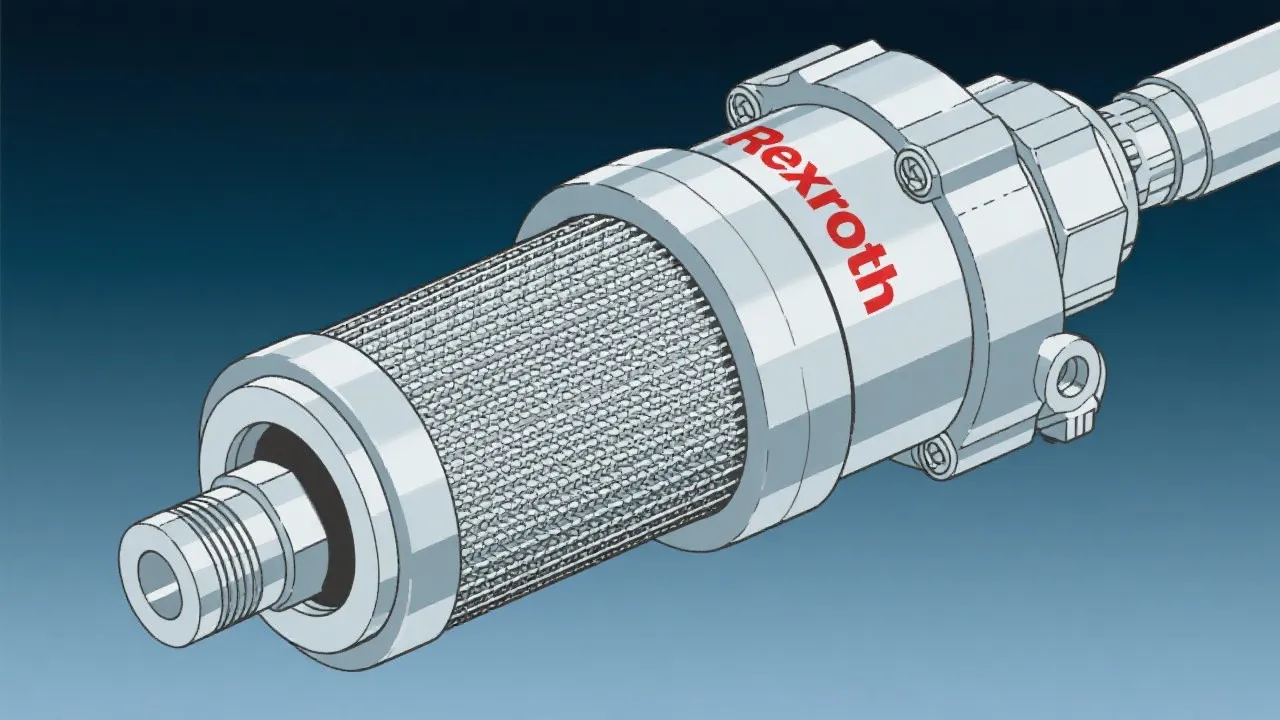

Rexroth's filter range includes various designs and capabilities. These include pressure filters, return-line filters, and suction filters, each tailored for specific industrial needs. Pressure filters are positioned downstream from the pump, ensuring that only clean fluid enters the hydraulic circuit, preventing any potential damage. For example, in a hydraulic press application, maintaining clean hydraulic fluid can be the difference between flawless operation and costly machine failures.

Return-line filters capture contaminants before fluid returns to the reservoir, minimizing system wear. In applications where systems are frequently started and stopped, such as in mobile machinery, these filters play a significant role in maintaining fluid integrity between operations. Suction filters, often positioned at the intake side of pumps, protect against large particles that might damage the pump, which can be a costly repair if not managed adequately.

Beyond these common types, specialized filter solutions, such as vent filters and oil filters, further expand Rexroth's product range to suit a variety of applications. Each filter type is designed with specific features tailored to the unique challenges presented by the operational environment, such as resistance to contamination specific to hydraulic oils, temperature ranges, and pressures.

One of the distinguishing features of Rexroth Filters is their high dirt-holding capacity, which allows for longer service intervals and reduced downtime. They are engineered with multiple filtration layers, offering high filtration efficiency even in the very demanding conditions. This multi-layer design is crucial as it captures both large particles and ultra-fine contaminants that could otherwise compromise system performance.

Additionally, these filters are designed to withstand high pressures and temperatures, making them versatile for various industrial environments. They often include features like pressure differential indicators, which notify operators when a filter replacement is necessary, thus preventing the risk of system contamination during operation. The use of high-quality materials also contributes to the durability of the filters, ensuring longevity even under harsh working conditions.

Another significant advantage of Rexroth Filters is their environmental compatibility. Many of their filters are designed to minimize waste products through replaceable filter elements, allowing for easy maintenance without the need for complete filter replacement. This focus on sustainability not only reduces operational costs but also aligns with the increasing global focus on environmentally friendly manufacturing practices.

| Filter Type | Primary Function | Typical Applications |

|---|---|---|

| Pressure Filters | Protect hydraulic circuits by trapping contaminants before fluids circulate through the system. | Manufacturing, Construction, Aerospace |

| Return-Line Filters | Clean contaminated fluid before it goes back to the tank, extending the system life. | Automated Assembly Lines, Heavy Machinery |

| Suction Filters | Prevent large particles from entering the pump and damaging it. | Excavators, Loaders |

| Vent Filters | Filter air entering hydraulic tanks, preventing moisture and contaminants from entering the fluid. | Reservoirs, Tanks for Hydraulics |

| Oil Filters | Remove impurities from engine oils in hydraulic power units. | Automotive Hydraulics, Industrial Machinery |

When selecting a Rexroth Filter, customers need to consider several factors. These include compatibility with existing systems, pressure ratings, dirt-holding capacity, and environmental conditions where the equipment operates. It’s essential to consult with Rexroth or a trusted supplier to ensure the filters chosen will adequately meet the demands of the specific application.

One of the first considerations should be the specific requirements of the system in which the filter will be used. Factors such as the viscosity of the hydraulic fluid, temperature variations, and the potential for contaminated environments should drive the selection process. Different applications may often require filters with varying specifications, so understanding the operational conditions is crucial.

Another important aspect is maintenance and serviceability. Customers should seek filters that allow easy access for maintenance, ideally with features such as quick-disconnect fittings and user-friendly designs that facilitate straightforward element changes. Regular maintenance schedules should be discussed to determine optimal replacement intervals, reducing the risk of equipment failure.

Additionally, the cost-effective approach of selecting filters for long-term use yields better results. While it may be tempting to opt for the least expensive filters, the potential for increased downtime and maintenance should be factored into buying decisions. Considering the overall total cost of ownership—including maintenance and potential disruption to productivity—often proves to be more effective than initial purchase savings.

What industries benefit very much from using Rexroth Filters? Industries such as manufacturing, construction, and aerospace benefit greatly due to the high standards of performance and reliability required in these fields. Furthermore, the agricultural industry also stands to gain significantly as it relies heavily on hydraulic systems for various farming equipment. Ensuring these machines operate with clean fluids not only prolongs life but enhances efficiency, which is critical in high-demand cultivation periods.

How often should Rexroth Filters be replaced? The replacement frequency depends on the application and operating environment. However, regular inspections as part of maintenance schedules can help determine the optimal replacement intervals. For instance, in applications with high levels of contamination, filters may need to be replaced more frequently compared to cleaner environments. On average, many systems perform well with filter elements changed every 500 to 1,000 hours of operation, but this can vary significantly.

Are Rexroth Filters compatible with systems from other manufacturers? Yes, Rexroth Filters are designed to be highly compatible with a range of systems, but it’s advisable to consult technical guidance for specific configurations. Considering compatibility helps to avoid any system inefficiencies that can occur from mismatched components. Utilizing filters specifically designed for the system can lead to improved reliability and overall functionality.

What maintenance is required for Rexroth Filters? Maintenance requirements for Rexroth Filters include periodic inspections for leaks, pressure checks, and timely replacements of filter elements based on usage and contamination levels. The use of pressure differential indicators greatly assists operators in monitoring filter performance and determining when servicing is necessary. Keeping thorough maintenance logs aids in recognizing patterns that might inform when filters should be serviced or replaced.

Rexroth Filters are indispensable in ensuring the high performance and efficiency of hydraulic systems across a multitude of industries. By maintaining cleanliness and preventing contamination, these filters extend the life of critical components and reduce downtime, culminating in cost savings and enhanced productivity. With a diverse range of filters available, Bosch Rexroth continues to provide solutions that meet the evolving needs of industrial technology.

As industrial applications continue to grow more complex, the need for reliable filtration systems like Rexroth Filters becomes even more paramount. Companies seeking to enhance their hydraulic systems should look towards advanced filtration solutions to maintain optimal operations. Investing in high-quality Rexroth Filters will not only protect essential equipment but also promote a culture of efficiency and reliability within industrial operations.

In a world where every minute of machine downtime can translate to significant financial loss, the role of reliable, efficient hydraulic filters cannot be overstated. The landscape of industrial machinery is continuously evolving, and with it comes the constant need to ensure that hydraulic systems remain clean and free from contaminants. Rexroth has positioned itself as a leading provider of these crucial components, dedicated to helping industries overcome the challenges presented by wear and contamination.

Through innovation and a commitment to advancing hydraulic technology, Bosch Rexroth is well-suited to tackle the present and future needs of industrial filtration, pushing the boundaries of what filters can achieve in enhancing system performance and reliability.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!