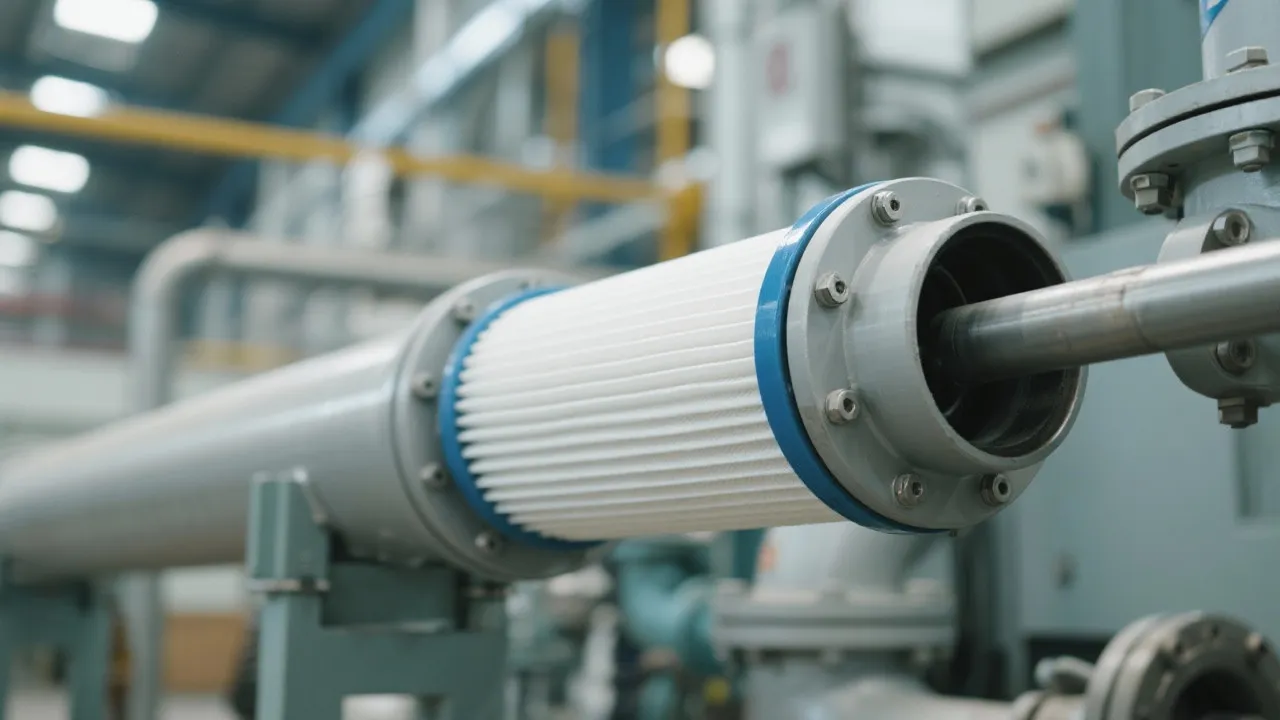

Rexroth Filters are essential components in industrial systems, ensuring optimal performance by removing contaminants from fluids. These filters are crucial for maintaining machinery efficiency and longevity. This article explores the technical aspects, applications, and advantages of Rexroth Filters in various industrial contexts, emphasizing their importance in operational success.

In the world of industrial machinery, Rexroth Filters play a pivotal role in maintaining the integrity and performance of various systems. Essential for removing contaminants from hydraulic fluids and lubricants, these filters ensure that machine components operate smoothly and efficiently. By focusing on the core principles of engineering and design, Rexroth Filters are engineered to meet high-performance standards across various industries, including automotive, manufacturing, and heavy equipment. The significance of incorporating advanced filtration solutions into machinery cannot be understated, as every minor enhancement contributes to a greater operational efficacy.

The importance of a well-functioning filtration system, like Rexroth Filters, cannot be overstated. Contaminants, even at microscopic levels, can significantly affect machinery’s productivity and longevity by causing wear and tear, corrosion, and blockages. This is especially crucial in sectors where precision and reliability are paramount, such as aerospace and medical equipment manufacturing. Thus, integrating robust filtration systems is vital for preventing unnecessary downtime and costly repairs, enhancing the reliability and life span of industrial equipment. An effective filtration system not only ensures optimal machinery function but also reduces waste and environmental impact by decreasing the frequency of hydraulic fluid replacement and system cleaning processes.

Renowned for their durability and efficiency, Rexroth Filters are designed with a variety of features to optimize performance:

Rexroth Filters find applications in a wide range of sectors, each benefiting from the integrity and performance improvements these filters provide:

| Feature | Rexroth Filter | Competitor Filter |

|---|---|---|

| Dirt Holding Capacity | High | Moderate |

| Filtration Efficiency | Superior | Good |

| Design Robustness | Robust | Standard |

| Temperature Range | Wide Range | Narrow Range |

| Material Quality | High-grade materials | Standard materials |

By comparing Rexroth Filters to their competitors, one can see that the additional investment in these high-quality filters often pays off in reduced maintenance requirements, fewer breakdowns, and extended equipment lifespan.

Ensuring the optimum performance of Rexroth Filters involves adherence to several top practices:

Regular inspections should be conducted monthly, with replacements as necessary, depending on the specific application and operational environment. More rigorous applications may require additional frequency adjustments to ensure optimal performance.

Yes, these filters are designed to operate efficiently in a wide range of temperatures, providing reliable performance in various conditions. Testing ensures their reliability, whether in extreme cold or heat.

They are versatile and suitable for numerous applications. However, specific industry requirements should always be consulted to ensure compatibility. For example, in pharmaceutical manufacturing, unique regulations may dictate stringent filtering requirements.

Failing to replace a filter on schedule can lead to reduced efficiency, increased contamination in the hydraulic fluid, and subsequent premature wear of internal components. In extreme cases, it could result in costly equipment failures, leading to unexpected downtime and repair expenses.

While Rexroth Filters may initially appear to have a higher price point, their superior quality, longer service life, and reduced maintenance needs often lead to overall savings. The investment in a high-quality filter can yield considerable returns in terms of productivity and reduced operational costs.

Rexroth Filters can be purchased through authorized distributors, online retailers, or directly from the manufacturer's website. It's advisable to ensure that you are buying from reputable sources to get genuine products that uphold quality standards.

The future of industrial filtration is evolving with advancements in technology and an increasing emphasis on efficiency and sustainability. Innovations in materials, such as nanofiber technology, promise to improve filter performance by enhancing dirt-holding capacity while reducing pressure drops. Researchers are exploring self-cleaning pipes and filters that could substantially decrease maintenance requirements, making filtration systems more user-friendly and reliable.

With ongoing regulations concerning environmental management and operational efficiency, companies are under pressure to implement solutions that not only comply with laws but actively contribute to sustainability goals. Rexroth Filters play a critical role in this aspect by ensuring that machinery runs cleanly and efficiently, which can help manufacturers meet stringent environmental standards. Furthermore, as industries move toward greener practices, the demand for advanced filtration solutions will inevitably increase, positioning Rexroth Filters as a significant player in future developments.

In summary, Rexroth Filters are an indispensable component of modern industrial machinery, critical for ensuring the cleanliness and efficacy of hydraulic and lubrication systems. Their advanced features, broad applicability, and the emphasis they place on maintenance highlight their supremacy over standard filtering options. As industries continue to evolve and environmental demands intensify, the relevance of effective filtration systems like Rexroth will only grow. Organizations that prioritize clean operations and invest in high-quality filtration solutions not only protect their machinery but also enhance their competitive advantage in the marketplace.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!