This article delves into the significance and operational efficiency of Rexroth Filter systems in industrial applications. Renowned for their reliability, these filters play a crucial role in multiple industrial settings by ensuring that hydraulic systems run smoothly and at optimal efficiency. We explore their designs, applications, and benefits to assist businesses in making informed decisions.

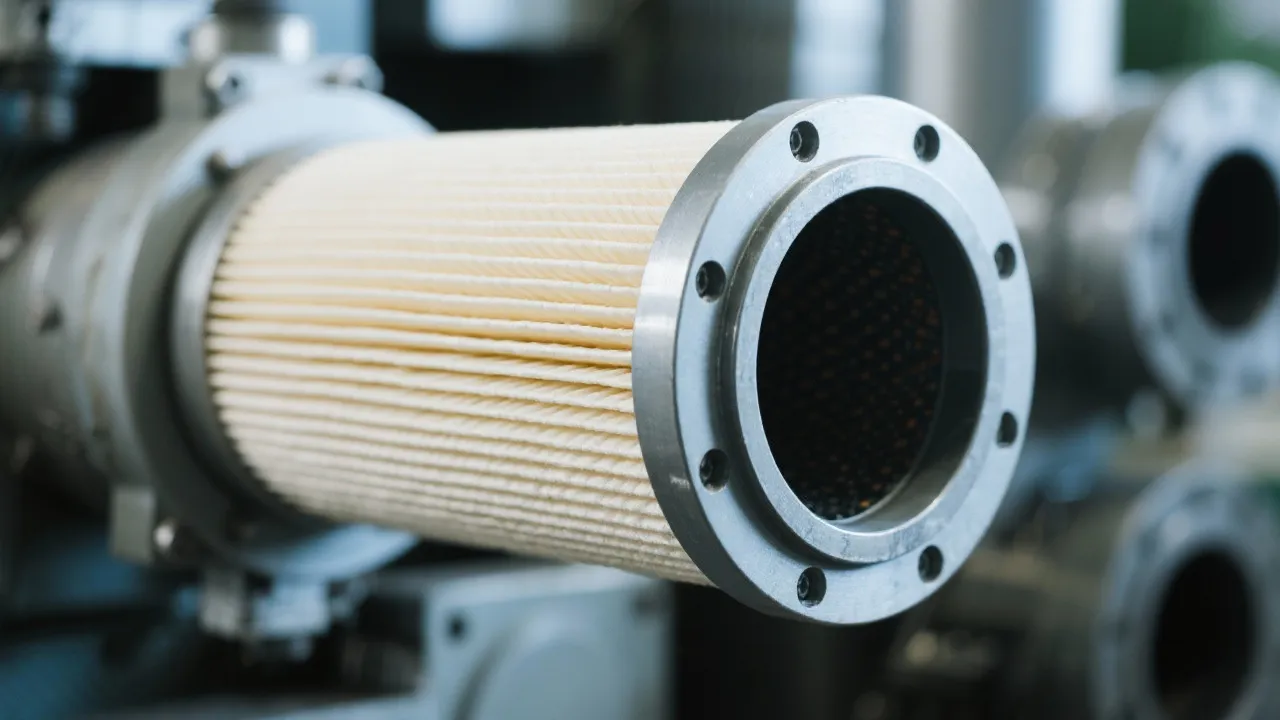

Rexroth Filters are integral components in maintaining the efficiency and longevity of hydraulic systems. Manufactured by Bosch Rexroth, a leader in the field of drive and control technologies, these filters are designed to remove contaminants and ensure the cleanliness of hydraulic and lubrication fluids. Their importance cannot be understated, as clean fluids are essential for the optimal performance of machinery and equipment across various industries. The advent of advanced filtration technologies has emphasized the need for high-quality filter solutions, thereby positioning Rexroth Filters as a cornerstone in modern hydraulic applications.

In industrial settings, the purity of fluids is paramount. Contaminants can cause wear, corrosion, and failure in hydraulic components, leading to costly downtime and repairs. Fluid contaminants can include particles such as dirt, metal shavings, water, and even microorganisms, which can severely affect the functionalities of hydraulic circuits. Rexroth Filters are engineered to meet these challenges effectively, delivering high performance in harsh environments and demanding applications. This makes them a preferred choice for industries ranging from manufacturing to automotive and aerospace.

Furthermore, the cost implications of not utilizing proper filtration can be significant. For instance, maintenance costs due to unplanned repairs often accumulate when systems are not equipped to handle contaminant loads. Additionally, there are safety considerations; hydraulic failures can lead to hazardous situations in workplaces. Therefore, investing in robust filtration systems not only enhances operational efficiency but also increases safety. Rexroth Filters play a significant role in this area by ensuring that the hydraulic systems operate not just effectively, but safely.

Rexroth Filters are employed across a diverse range of applications. In mobile and industrial hydraulics, they ensure that fluid flows remain unobstructed and systems perform effectively. Mobile applications such as construction machinery, agricultural equipment, and material handling vehicles benefit greatly from Rexroth Filters, as they help maintain system reliability in variable conditions. In manufacturing environments, these filters contribute significantly to machinery efficiency and longevity, enhancing overall productivity. For example, in assembly lines where hydraulic robots operate, the continuous clean operation ensures that machinery downtime is minimized, allowing for smoother operation and increased output.

Furthermore, in the automotive sector, they support the smooth operation of vehicles. Hydraulic systems in modern vehicles—such as brakes, power steering, and suspension systems—require precise functioning to ensure user safety and comfort. Similarly, in aerospace, they guarantee that safety and performance standards are consistently met. The high-pressure hydraulic systems of airplanes and helicopters require filtering solutions that can withstand extreme conditions while ensuring that performance is never compromised. Given the critical nature of these applications, the reliability of Rexroth Filters in maintaining fluid cleanliness is a game changer.

Rexroth Filters are distinguished by several features that enhance their functionality. They offer robust construction and high dirt holding capacity, which translates to longer service intervals and reduced maintenance costs. The design of Rexroth Filters incorporates premium materials that can withstand chemical exposure and physical wear, resulting in improved lifespan and durability. Additionally, their precision engineering ensures that they effectively filter out debris, particles, and moisture, protecting the integrity of hydraulic systems. The filters also provide low pressure drop, ensuring that the energy required to push fluids through the system is minimized. This feature not only conserves energy, which translates to cost savings, but also contributes to the overall efficiency of the system.

Moreover, many Rexroth Filters are designed with user-friendly features such as visual inspection indicators that allow operators to easily monitor filter conditions. Some models come equipped with differential pressure indicators that signal the need for a filter change, thus preventing unnecessary downtime. The ability to integrate with existing hydraulic systems seamlessly adds to the versatility of these filters. They are available in various sizes and configurations, making it easy for businesses to find the right fit for their specific needs.

When selecting a Rexroth Filter, businesses should consider factors such as the specific requirements of their hydraulic system, operating conditions, and the type of fluid being filtered. The selection of an appropriate filter ensures optimal performance and extends the life of the system. For instance, the specific viscosity of the hydraulic fluid, the operating temperature range, and potential chemical exposure must all be considered. Bosch Rexroth provides a wide range of options and expert support to guide customers in making the right choice for their applications.

Additionally, understanding the application environment may dictate the need for specific filter types. For example, a filter used in a dusty environment may need to be engineered differently than one in a relatively clean environment. It's essential also to consider the maintenance capabilities of the organization. A robust filter solution that can operate effectively with minimal maintenance might be more suited for remote operations where access is limited. Each application has unique demands, and the wrong filter choice can lead to inefficiencies and increased costs.

| Feature | Rexroth Filters | Other Brands |

|---|---|---|

| Dirt Holding Capacity | High | Varies |

| Pressure Drop | Low | Varies |

| Material Robustness | Excellent | Depends on Brand |

| Maintenance Requirements | Minimal | Varies |

| Compatibility with Fluids | Wide Range | Limited |

| Cost-Effectiveness | High Value | Can Vary |

Q: What industries benefit very from using Rexroth Filters?

A: Industries such as manufacturing, automotive, aerospace, and mobile hydraulics benefit significantly from the use of Rexroth Filters due to their reliability and efficiency in removing contaminants. The ability to scale operations while maintaining optimal performance makes them crucial in high-stakes environments.

Q: How often should Rexroth Filters be replaced?

A: The replacement interval depends on the operating conditions and system requirements. However, their high dirt holding capacity often means longer intervals between replacements. Routine checks, typically conducted during standard maintenance schedules, should include assessing the filter condition to determine if a replacement is needed.

Q: Can Rexroth Filters be used with all types of hydraulic fluids?

A: Yes, Rexroth Filters are compatible with a wide range of hydraulic and lubrication fluids, ensuring versatility in various applications. It is crucial, however, that the selected filter model is specified for the fluid characteristics, such as viscosity and chemical composition, to ensure it performs at an optimal level.

Q: What are the economic advantages of choosing Rexroth Filters?

A: The economic advantages stem from their low maintenance costs, extended service intervals, and reduced likelihood of system failures. When factoring in the downtime and repair costs associated with inadequate filtration, Rexroth Filters prove to be a cost-effective solution in the long run. Firms looking to optimize their operational budgets will find that investing in high-quality filtration pays off in reduced maintenance and increased system reliability.

Q: What innovations have been introduced in Rexroth Filters recently?

A: Recent innovations in Rexroth Filters include advancements in filter media technology to enhance contaminant retention and extend service life. There have also been developments in digital monitoring systems that allow for real-time performance tracking, leading to predictive maintenance capabilities that can further reduce downtime and maintenance costs.

In conclusion, Rexroth Filters stand out as a reliable and efficient solution for maintaining clean and effective hydraulic systems. Their robust construction, high dirt holding capacity, and lower maintenance requirements make them an invaluable asset across diverse industrial applications. Adopting Rexroth Filters not only ensures compliance with operational demands but also drives sustainability by minimizing waste and resource consumption through efficient performance. As industries increasingly focus on optimizing processes and reducing their environmental footprint, the role of high-quality filtration solutions like Rexroth Filters cannot be overstated. By prioritizing the filtration of their hydraulic systems, businesses are placing a strong emphasis on their operational excellence and longevity, ensuring that they are well-positioned for future challenges in a rapidly evolving industrial landscape.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!