Rexroth Filters are essential components in industrial machinery, designed to remove contaminants and ensure efficient operation. They play a crucial role in maintaining the cleanliness and longevity of systems used in various industries such as manufacturing, agriculture, and automotive, by filtering particles from liquids and gases.

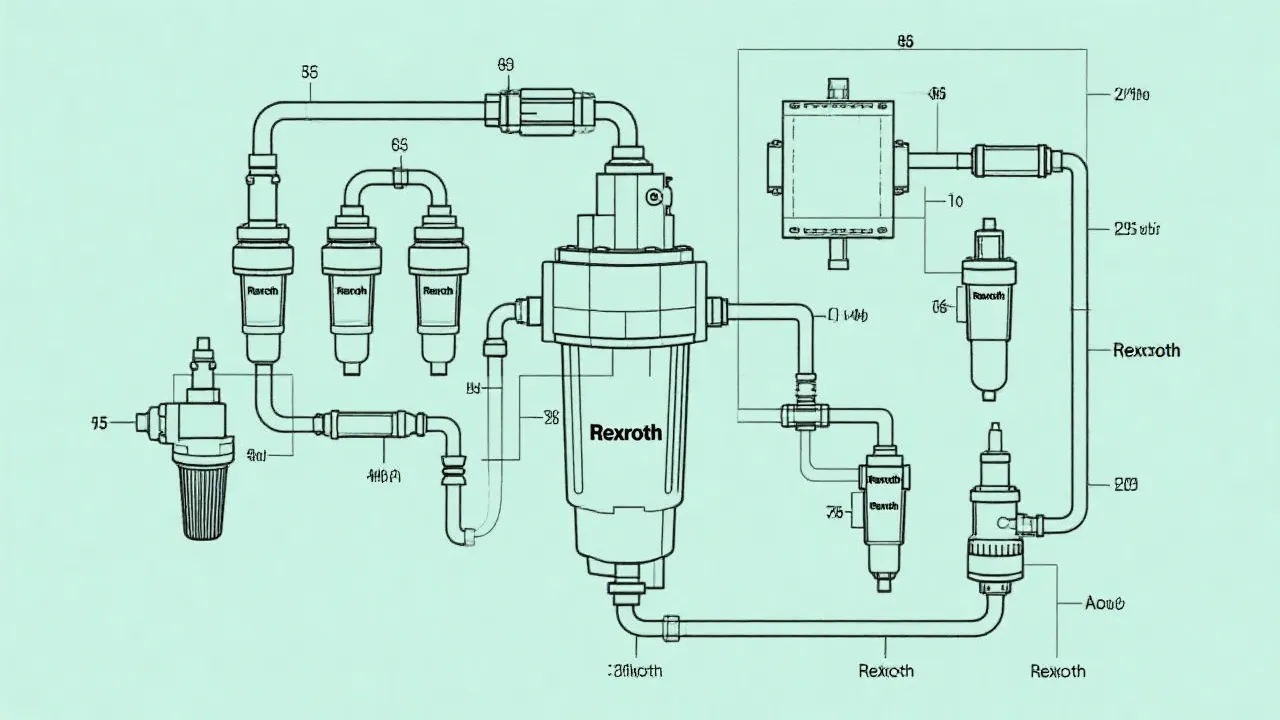

Rexroth Filters are pivotal in the seamless operation of hydraulic and pneumatic systems, contributing significantly to machine efficiency by filtering out contaminants. These filters are commonly used in diverse industrial applications including manufacturing machinery, agricultural equipment, and automotive systems. By ensuring the removal of unwanted particles, they help maintain system reliability, efficiency, and longevity. Rexroth Filters' advanced design and engineering allow them to perform exceptionally in a variety of environments, ensuring that systems run smoothly and with minimal downtime.

The industrial environment is inherently challenging, with dust, debris, and various contaminants present in the working atmosphere. Rexroth Filters are engineered to effectively capture these particulates before they can cause damage to the machinery, thus preventing potential breakdowns and costly repairs. By utilizing advanced filtration technology, these filters help maintain a stable and secure operation, contributing to overall safety and productivity in industrial processes. This is particularly important in sectors like aerospace and pharmaceuticals, where microscopic contaminants can compromise the integrity of products and safety standards.

In industrial settings, various types of contaminants can affect equipment performance. These include:

The ongoing presence of these contaminants underscores the importance of investing in high-quality filtration systems like Rexroth Filters.

One key feature of Rexroth Filters is their innovative multi-layered filtration media, which provides high dirt-holding capacity and reliability under different operational conditions. The filters are available in various specifications to suit distinct industrial needs. For instance, some models are designed to withstand high pressure, while others focus on maximizing flow rate. This versatility ensures that there is a suitable Rexroth Filter for nearly every application.

| Model | Pressure Capacity | Flow Rate | Material |

|---|---|---|---|

| Rexroth LE series | Up to 315 bar | 245 L/min | Steel |

| Rexroth R series | Up to 210 bar | 300 L/min | Aluminum |

Moreover, Rexroth Filters employ various technologies such as depth filtration and surface filtration to maximize their efficacy. Depth filtration is ideal for capturing larger volumes of contaminants, while surface filtration excels in trapping finer particles. Understanding the differences between these methods is crucial for selecting the appropriate filter for specific applications.

Selecting the appropriate filter for your needs depends on several factors. It's crucial to consider the pressure capacity, the system's flow requirement, and the nature of the contaminants present in your operational environment. Consulting with an expert or supplier can help you make an informed decision, ensuring optimal performance and protection of your industrial system. To further aid in this selection process, a comprehensive analysis of the existing system performance and contamination sources can provide valuable insight into the specific filtering requirements.

Proper installation of Rexroth Filters is essential for achieving optimal filtration performance. Here are some key considerations to keep in mind during installation:

By adhering to installation guidelines and regularly checking the conditions around the filters, users can vastly improve operational reliability and reduce unnecessary maintenance efforts.

A practical example of the effectiveness of Rexroth Filters can be seen in the automotive industry, where hydraulic systems often handle numerous operations, from steering to braking. In one case study, a major automotive manufacturer reported significant reductions in maintenance costs after implementing Rexroth Filters into their hydraulic systems. By replacing their existing filters with Rexroth models, they noted a decrease in contamination levels by over 50%, leading to prolonged equipment life and fewer production delays.

Similarly, in the manufacturing sector, a company dealing with high-precision machining underwent a major overhaul of their hydraulic circuit, integrating Rexroth Filters tailored to handle fine metal shavings often produced during the machining process. Over the course of several months, they observed a measurable increase in operational efficiency and a notable decrease in downtime caused by filter clogging. The change underscored the importance of selecting appropriate filtration solutions tailored to the specific challenges faced within their operations.

Rexroth Filters stand as an indispensable tool in the optimization of industrial operations. As a critical safeguard against contamination, they help preserve the functionality of systems, minimize maintenance efforts, and ensure the safety of demanding industrial environments. For businesses aiming to enhance their operational efficacy, investing in high-quality Rexroth Filters remains an informed choice. With the variety of options available and the proven track record of their effectiveness across multiple industries, Rexroth Filters not only provide a robust solution to contamination challenges but also support the broader goals of sustainability and operational excellence.

As industries evolve, so do the technologies utilized in filtering systems. Companies like Rexroth continually innovate to improve filtration processes, enhancing their effectiveness and efficiency. Recent advancements include the development of smart filtration systems that integrate IoT (Internet of Things) technology. These systems monitor fluid quality in real-time, notifying operators of any deterioration in filtration performance or the presence of contaminants, thus allowing for proactive maintenance and filter replacements.

Automatic cleaning mechanisms are also being introduced in some high-usage applications. These systems periodically flush contaminants from the filter media without requiring manual intervention, thus ensuring optimal filtration continuously. Additionally, the integration of biodegradable filter materials is gaining traction as companies strive to meet environmental sustainability goals while maintaining high-performance standards.

In summary, Rexroth Filters represent a critical component of modern industrial systems, combining innovative technology with proven efficacy to meet the demands of complex operational environments. Their ability to enhance equipment longevity, reduce maintenance costs, increase system efficiency, and improve safety standards makes them a valuable investment for industries across the board. It is essential for businesses to remain informed about the latest advancements in filtration technology and adapt accordingly, ensuring they capitalize on all potential benefits offered by high-performance filtration solutions.

For those interested in diving deeper into the world of filtration technology and the specific contributions of Rexroth Filters, several resources are available:

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!