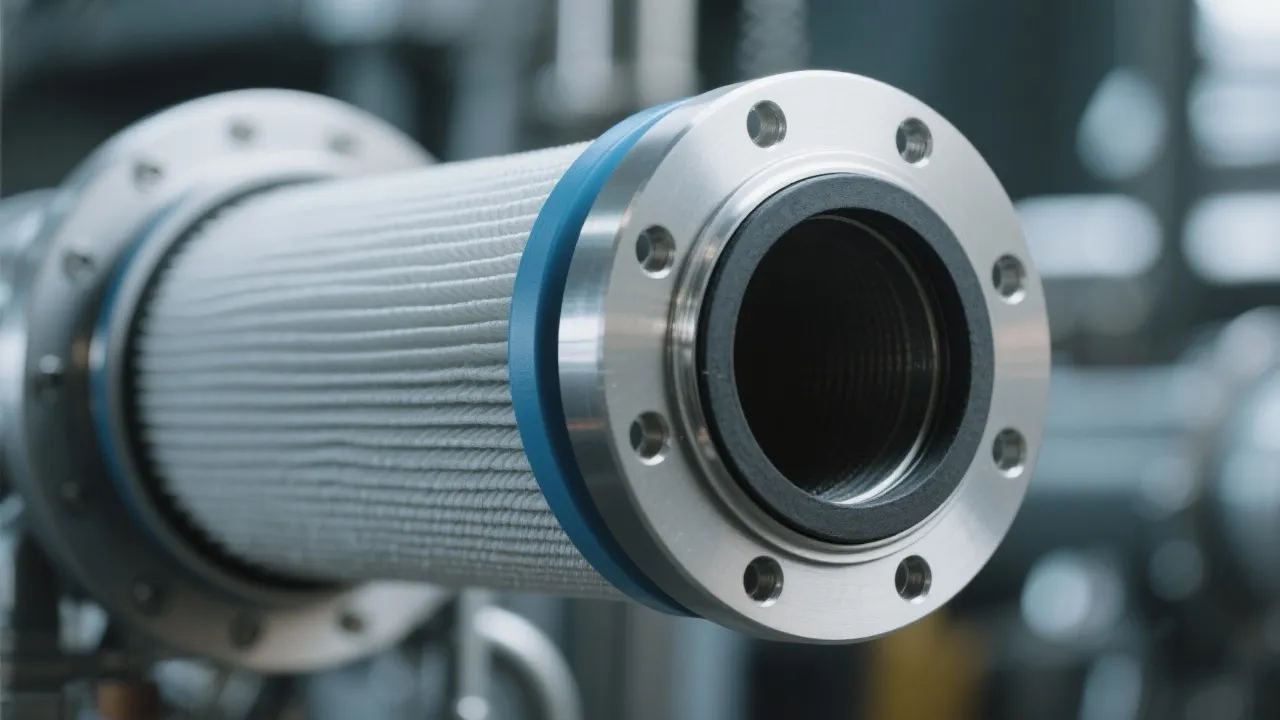

Rexroth filters are essential components in fluid management systems, promoting system efficiency and longevity by removing contaminants. These filters are prevalent in industries requiring precision and reliability. This guide provides an expert overview of their functions, benefits, and applications, offering insights into their critical role in industrial operations.

The Rexroth filter stands as a critical component in modern industrial systems, renowned for its reliability and efficiency in managing fluid cleanliness. Highly regarded in various sectors, these filters play a pivotal role in maintaining the operational integrity of machinery by mitigating the risks posed by contaminants. In this comprehensive analysis, we delve into the myriad applications, benefits, and nuances associated with Rexroth filters, offering industry professionals invaluable insights into their selection and maintenance.

In any industrial setting, the integrity of fluid systems is paramount. Contaminated fluids can lead to system failures, costly downtime, and reduced equipment life. Rexroth filters, therefore, become indispensable assets in ensuring that hydraulic and lubricating systems operate efficiently. By trapping dirt, particulates, and other impurities, these filters significantly reduce the risk of wear and tear on the machinery.

A clean fluid system enhances performance by maximizing the efficiency of hydraulic equipment. It allows pumps to operate at optimal performance levels, leading to increased energy efficiency, which can translate to lower operational costs. Furthermore, clean fluid systems contribute to lower maintenance costs as they are less likely to cause equipment failure, which could necessitate more extensive repairs or even full component replacements.

Rexroth filters are widely used across varied industries, from manufacturing and construction to automotive and aerospace sectors. Their ability to sustain high-pressure environments while effectively removing contaminants renders them an ideal choice for hydraulic systems, lubrication circuits, fuel lines, and process equipment. The adaptability of Rexroth filters to different fluid types and operational demands further cements their reputation as versatile and high-performing components.

In manufacturing, Rexroth filters are employed in CNC machinery to ensure precision and accuracy by maintaining fluid cleanliness within hydraulic systems. In construction, these filters protect heavy machinery from contamination that could result from exposure to dirt, debris, and other environmental factors. Automotive applications leverage these filters within engines and fuel delivery systems to enhance the performance and reliability of vehicles, safeguarding crucial components from impurities.

Aerospace applications have their unique challenges, often requiring filters that can perform under extreme conditions. Rexroth filters are tailored to meet these conditions, ensuring that fuel systems and hydraulic controls operate seamlessly even in high-altitude, low-pressure environments. This adaptability across diverse sectors underlines the pivotal role Rexroth filters play in industrial operations.

The benefits of Rexroth filters extend beyond just operational metrics. Their ability to maintain clean fluids helps enhance the performance of auxiliary systems as well, such as those involving cooling and lubrication. For example, in an automotive context, cleaner oil can improve fuel efficiency, which not only saves costs but also results in lower emissions, aligning with sustainable practices and regulations.

Furthermore, many industries are increasingly pressured to adopt recognized international standards for quality and sustainability. Using Rexroth filters can aid companies in achieving certifications such as ISO 9001, as clean and reliable fluid management systems contribute significantly to quality assurance and product consistency. Such strategic advantages make Rexroth filters not just beneficial but essential in competitive markets.

Choosing the appropriate Rexroth filter for specific applications requires an understanding of the system's operational needs and environmental conditions. Key considerations include:

In addition to these primary considerations, it can also be prudent to evaluate the filter's dirt-holding capacity, which indicates how much contaminant material it can retain before requiring maintenance. This factor becomes crucial in operations that involve high levels of particulate contamination, as filters with higher dirt-holding capacities tend to require less frequent replacement. Analyzing these factors enhances the decision-making process and helps secure the optimal performance of the application in question.

Regular maintenance is crucial to extend the life and effectiveness of Rexroth filters. Practices such as timely filter replacement, monitoring fluid quality, and maintaining system cleanliness can significantly boost the longevity of filters. Implementing a proactive maintenance schedule not only supports the optimal performance of filters but also contributes to the overall health of the entire fluid management system.

Maintenance practices should include establishing a monitoring system to track filter performance and condition. This could involve installing pressure gauges that provide real-time data on filter status, indicating when a filter is becoming clogged or no longer able to perform effectively. Regular checks of the hydraulic fluid for contamination levels can also inform maintenance requirements, allowing companies to anticipate and mitigate risks before equipment failure can occur.

Moreover, documenting maintenance activities can provide valuable insights for future reference. This documentation can help identify patterns concerning the lifespan of filters under different conditions, which can assist in developing better maintenance schedules and filter selections moving forward. Establishing a culture of proactive maintenance fosters a mindset focused on operational excellence and sustainability within the organization.

| Filter Type | Application | Benefits |

|---|---|---|

| Hydraulic Filters | Hydraulic systems in various machinery | Protects hydraulic components from wear and failure |

| Lubrication Filters | Lubrication circuits in engines | Enhances engine efficiency and lifespan |

| Fuel Filters | Fuel lines in automotive applications | Ensures clean fuel supply, reducing engine wear |

| Air Filters | Air intake systems in diesel engines | Prevent engine degradation from dust and contaminants |

| Fine Filters | Precision applications in laboratories or pharmaceuticals | Ensures contamination-free process flow, upholding product integrity |

As technology evolves, so do the filters themselves. Rexroth is at the forefront of adopting advanced technologies to improve the performance and functionality of their filters. Innovations such as synthetic filtration media, which offer greater surface area and improved dirt-holding capacity while minimizing back pressure, are being integrated into modern designs. Such advancements can also allow for higher flow rates without compromising filtration efficiency, making them suitable for demanding applications.

Another area of technological development includes the integration of smart sensors into filtration systems. These sensors can provide real-time data on filter health, fluid quality, and system performance. For instance, IoT-enabled filters can alert operators about impending filter blockages and necessary maintenance, thereby reducing the risk of unplanned downtime. This connectivity also enables the compilation of data analytics, which can support better decision-making in maintenance and operational strategies.

Moreover, advancements are being made in the area of filter materials. With a growing emphasis on sustainability, Rexroth is exploring biodegradable filtration materials that maintain high-performance levels while reducing environmental impact. These materials can offer comparable performance to traditional synthetic alternatives but with a lower ecological footprint.

Despite the advancements in filtering technology, several challenges remain in ensuring optimal filter performance over time. One significant challenge is the compatibility of filter materials with various fluids. Reactive chemicals can degrade certain filter media, leading to premature failure and inefficiencies. Manufacturers must ensure that newer materials can withstand the demanding conditions often encountered within industrial applications.

Contamination sources also pose a consistent challenge. Identifying and managing these sources is crucial in maintaining fluid cleanliness. Operators must conduct thorough monitoring and maintenance programs to detect contaminant influx before it affects the fluid system. The maintenance program should also take into account seasonal changes or shifts in operational workloads that could introduce additional contaminants.

Another concern is not only the removal of contaminants but also the potential for filter media to release trapped particles back into the flow after reaching saturation point. Regular checks need to be performed to prevent this from occurring, which may involve scheduled replacements or cleaning regimes to maintain performance standards.

In conclusion, Rexroth filters play an integral role in modern industrial applications, contributing significantly to equipment performance and operational efficiency. Their robust design and advanced filtration capabilities make them suitable for a wide array of applications, ensuring that clean fluid systems are maintained even in the most demanding environments. Understanding the importance of filter selection, maintenance, and the latest technological advancements are essential for professionals looking to optimize their machinery operations.

As industries continue to evolve and face new challenges, the relevance of high-quality filtration solutions like Rexroth filters will only grow. Investing in the right solutions not only preserves the integrity of fluid systems but also propels industries towards improved productivity, sustainability, and compliance with environmental regulations. Embracing these filtration solutions today offers a foundation for success in the future, making them a critical consideration in any industrial strategy aimed at achieving operational excellence.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!