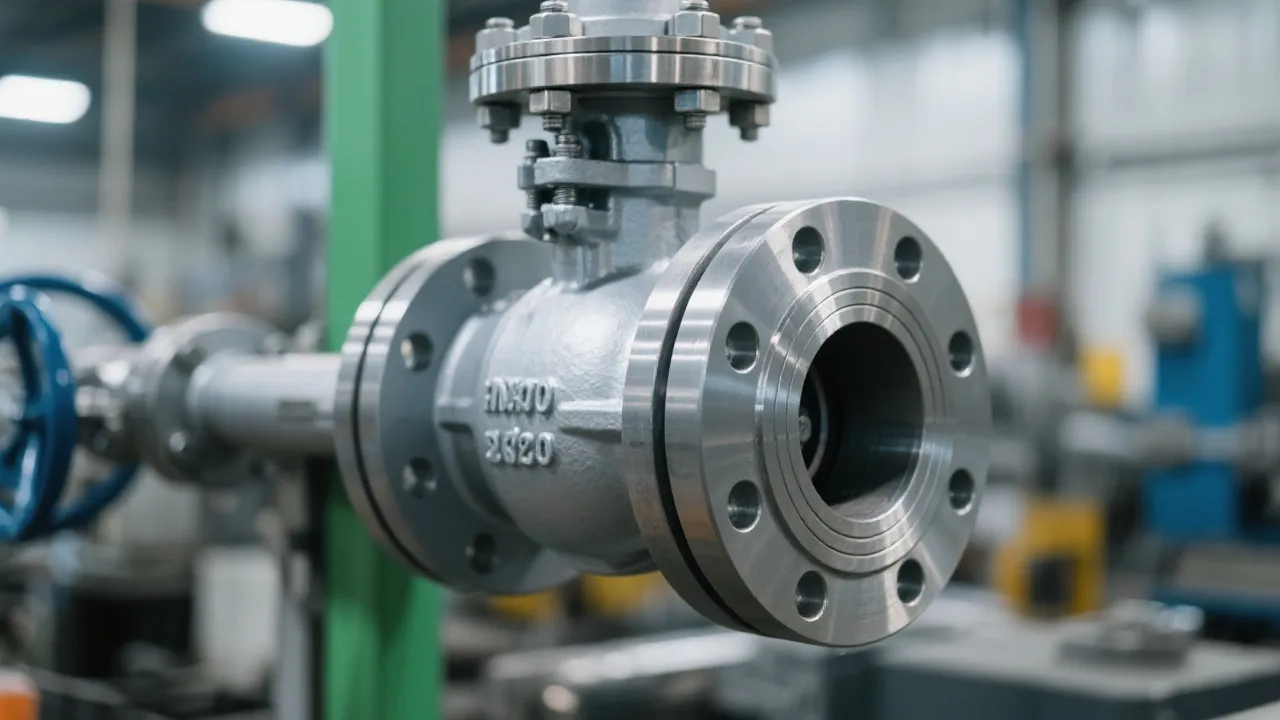

Rexroth Valves play an integral role in fluid control systems within various industries. Known for their reliability and precision, these valves are essential components in hydraulic and pneumatic applications. This article delves into the functionality, types, and applications of Rexroth Valves, providing a thorough understanding for professionals and enthusiasts alike.

Rexroth Valves are vital components in hydraulic and pneumatic systems, renowned for their precision engineering and unmatched reliability. These valves are instrumental in regulating fluid flow, maintaining pressure, and ensuring optimal performance of machinery across multiple sectors, including manufacturing, automotive, and aerospace. Understanding Rexroth Valves is crucial for anyone involved in industrial automation and fluid dynamics. With a storied history of innovation, Rexroth has established itself as a leader in the field of motion control and automation technology, producing solutions that help businesses achieve operational excellence.

The significance of Rexroth Valves is not merely in their functionality; they embody a plethora of engineering principles, ranging from material science to fluid mechanics. This introduction sets the stage for diving deeper into the technical specifications, performance metrics, and operational environments of these essential hydraulic and pneumatic components.

The hallmarks of Rexroth Valves are their durability and efficiency. Built to withstand harsh industrial environments, these valves offer a range of benefits. Both mechanical and electronic features work together seamlessly to enhance operational parameters. Here are the core aspects comprehensively explained:

The advanced engineering behind Rexroth Valves translates to a broader impact on overall system performance, resulting in heightened productivity, reduced costs, and increased competitiveness within various industries.

The Rexroth lineup features a comprehensive range of valves, each suited to specific tasks and applications. These different types of valves provide unique capabilities that allow users to choose the right valve for their operational needs:

Each type of valve is engineered with specific features and specifications to cater to the distinct needs of various applications, making Rexroth Valves a versatile addition to any hydraulic or pneumatic system.

Owing to their reliability and versatility, Rexroth Valves find applications in a wide variety of fields:

Each of these applications demonstrates how Rexroth Valves enhance operational efficiency, safety, and reliability in various environments, demonstrating their indispensable role across numerous industries.

The selection of the right Rexroth Valve depends on various factors, and making an informed decision can significantly enhance system performance. Here’s a closer look at essential considerations:

| Factor | Consideration |

|---|---|

| Application Type | Determine the specific needs, whether hydraulic or pneumatic demands greater precision or pressure control. Understand the nature of operations to identify suitable valve types. |

| Environmental Conditions | Consider exposure to temperature extremes or corrosive materials. This aspect influences the choice of materials and designs that can withstand harsh conditions. |

| Flow Rate Requirements | Ensure the valve supports the necessary flow rate for your operations, as inadequate flow can lead to inefficiency and performance issues. |

| System Pressure | Identify the maximum and minimum operational pressures to match the valve's capabilities, ensuring adequate performance without risking system integrity. |

Making the right choice when selecting Rexroth Valves not only aligns with operational needs but also enhances the reliability and efficiency of the overall system, reducing operational costs in the long run.

Q1: What makes Rexroth Valves suitable for industrial use?

A1: Their durability, precision, and adaptability across various applications make them an excellent choice for industrial settings. Enhanced reliability improves operational uptime and supports rigorous safety standards.

Q2: How often should Rexroth Valves be maintained?

A2: Regular maintenance is recommended bi-annually, but frequency can vary based on application intensity. For critical applications, a more rigorous schedule may be necessary, including checks for leaks, wear, and operational performance.

Q3: Are there environmental considerations when choosing a Rexroth Valve?

A3: Absolutely, factors such as ambient temperature, humidity, and exposure to corrosive substances should be carefully evaluated to ensure that the selected valve can perform optimally without premature failure.

Q4: Can Rexroth Valves be integrated into existing systems?

A4: Yes, their versatile design allows for easy integration with various system configurations, providing efficient enhancements. Customization is also available for unique requirements, maximizing operational compatibility.

As industries evolve and demand for energy-efficient, reliable solutions grows, the role of Rexroth Valves in automation and fluid control technologies will continue to expand. Ongoing innovations, including the integration of smart technology, are anticipated to further enhance their functionality. This shift will see valves equipped with sensors and IoT capabilities, allowing for real-time monitoring and precise control, thereby driving operational efficiency while reducing environmental impact.

Ultimately, whether in automotive systems, aerospace applications, or industrial automation, Rexroth Valves exemplify precision, efficiency, and reliability. They not only meet existing operational demands but also pave the way for future advancements. For industry professionals or enthusiasts looking to enhance their understanding or application of fluid control technologies, Rexroth Valves stand as a testament to engineering excellence, offering a reliable solution for modern industrial challenges. Ongoing training and education, combined with a commitment to embracing new technologies, will ensure that operators maximize the potential of these vital components, thereby contributing to smoother operations and greater efficiency in the workplace.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!