Rexroth Valves play a critical role in industrial fluid control, offering precision and durability in various applications. Known for their reliability and efficiency, these valves are integral in sectors ranging from manufacturing to automation. This guide explores their significance, functionality, and the dynamics of the global valve market, with expert insights to aid decision-making.

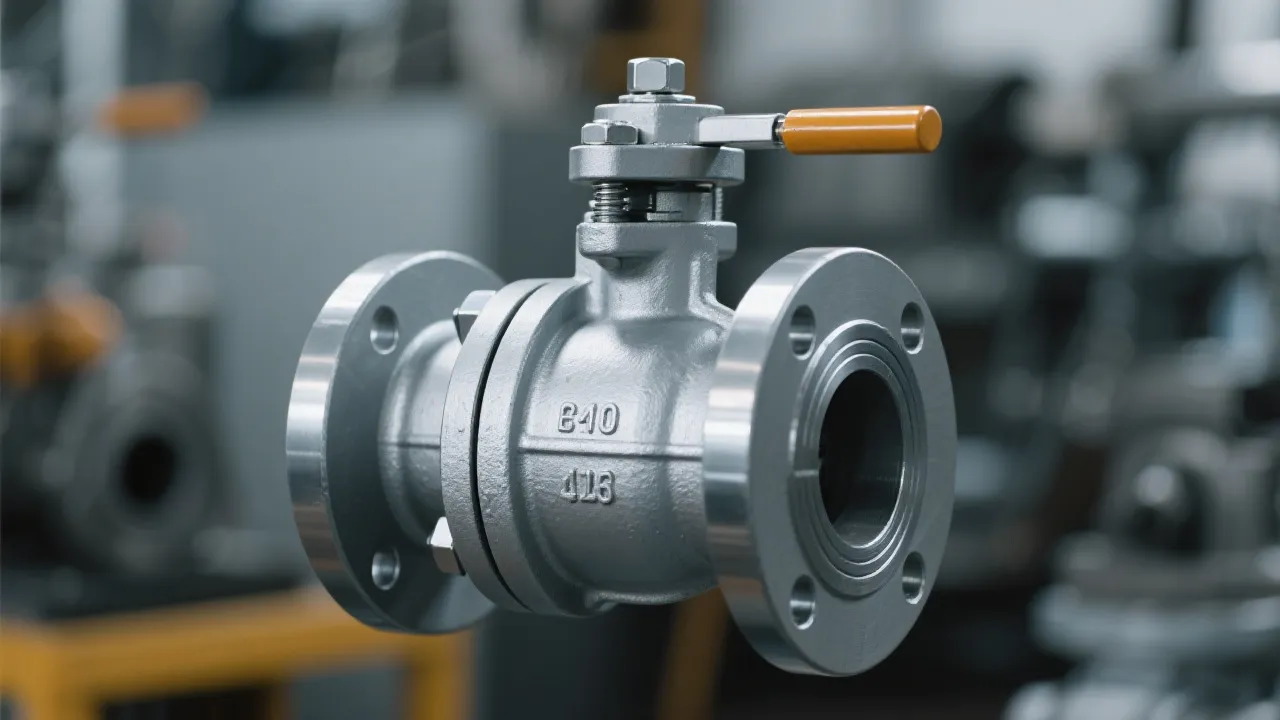

Rexroth Valves are pivotal components in the realm of industrial fluid control. Renowned for their precision and durability, these valves are employed across a myriad of applications, ensuring efficient fluid management which is essential for maintaining operational efficacy in diverse sectors like manufacturing, automation, and process industries. Their design and performance meet stringent industry standards, making them a preferred choice among professionals worldwide. The reliability of these valves not only enhances system productivity but also prolongs the lifetime of equipment, thereby providing a significant return on investment for industries that prioritize superior technology.

In industries where fluid dynamics play a critical role, the functionality of Rexroth Valves cannot be overstated. They are integral to systems that demand precise control of flow and pressure. These valves are engineered to withstand harsh conditions and high pressures, ensuring consistent performance and longevity. Therefore, they are commonly used in hydraulic and pneumatic systems, which require reliability and exactitude to function correctly. For instance, in hydraulic systems, Rexroth Valves facilitate fluid flow regulation that is critical for the operation of machinery such as excavators and forklifts, ensuring they operate smoothly and efficiently. This reliability is essential in maintaining safety standards, reducing downtime, and enhancing overall productivity.

A closer look at the applications of Rexroth Valves across different sectors reveals their extraordinary versatility. In the automotive industry, they regulate fluid flow within assembly lines, ensuring timely and efficient manufacturing processes. In the aerospace sector, high-performance Rexroth Valves are used for fluid control in landing gear systems, flight controls, and more, where precision is paramount due to strict regulatory standards. The food and beverage industry also benefits from these valves in process control, allowing for the accurate management of pumping and bottling processes that adhere to health and safety regulations.

Rexroth Valves are celebrated for their robust construction and innovative technology that enhances their efficiency. Some salient features include:

With continuous advancements in technology, Rexroth has incorporated intelligent controls and diagnostic features into their valve systems. This includes the integration of IoT technology allowing for remote monitoring of valve performance. Such innovations enable companies to make data-driven decisions regarding maintenance and operation, further enhancing operational efficiency. Smart control systems can predict potential failures before they occur, thereby preventing costly downtime and ensuring uninterrupted operations.

In today’s industrial landscape, sustainability is key. Rexroth Valves are designed with environmental considerations in mind, ensuring that they minimize energy consumption during operation. They often meet energy efficiency standards, contributing to lower operational costs and reduced carbon footprints. As industries worldwide pivot towards greener technologies, the demand for valves that support sustainable practices is likely to rise. Rexroth is at the forefront of this movement, developing solutions that not only meet but exceed current environmental regulations.

A: Their precision engineering, durability, and adaptability to specific applications are unmatched, supported by a company with a rich heritage in fluid control technology.

A: Common uses include manufacturing processes, automotive applications, aerospace, food and beverage industries, and any system requiring fluid power control.

A: Consider factors such as fluid type, pressure requirements, application environment, and specific performance outcomes desired in your project.

A: Yes, Rexroth Valves are designed to integrate seamlessly with a variety of other hydraulic components, making them versatile in mixed-system environments.

A: Routine inspections and regular maintenance are recommended. This includes checking for wear, ensuring seals are intact, and following manufacturer guidelines for optimal performance.

The global market for industrial valves, including Rexroth products, is projected to grow steadily as demand for automation in manufacturing processes increases. According to a report by MarketWatch, the industrial valve market is expected to expand at a CAGR of approximately 5% between 2021 and 2026. This growth is attributed to advancements in valve technology, the rising emphasis on energy-efficient processes, and an increased focus on operational safety within plants. Furthermore, as industries strive to implement Industry 4.0 technologies, the integration of smart, connected valves will play a crucial role in achieving operational efficiencies.

Rexroth's position within this market is strengthened by its commitment to innovation and quality. The company’s ongoing investment in research and development has led to the creation of next-generation valves that utilize cutting-edge materials and smart technology, ensuring they meet the evolving needs of various industries. This forward-thinking approach not only improves product performance but also enhances the overall reliability of fluid control systems.

Additionally, as companies face increased pressure to comply with stringent regulations regarding emissions and waste, Rexroth Valves offer solutions that help industries meet these challenges. The advancement of eco-friendly technologies in valve production and operation reflects a growing trend towards sustainability, which is likely to continue shaping market dynamics in the coming years.

As the industrial landscape continues to evolve, several emerging trends in fluid control technologies have gained prominence, each influencing the design and functionality of valves, including Rexroth’s offerings. One major trend is the increased focus on automation and control systems. With the introduction of artificial intelligence and machine learning, there is a growing demand for valves that can be easily integrated into automated systems, allowing for real-time adjustments to fluid flow and pressure based on system demands.

Another trend is the rise of predictive maintenance solutions powered by IoT technologies. By equipping valves with smart sensors, manufacturers can monitor operational metrics like temperature, pressure, and flow rates, transmitting this data to centralized systems where analyses can be conducted. This proactive approach prevents failures by allowing for timely maintenance before a breakdown occurs, ultimately reducing downtime and repair costs.

In line with evolving customer expectations, manufacturers are also increasingly keen on customizing solutions for specific applications. Rexroth, for instance, has resources that allow for modular designs, adapting their products to meet unique customer requirements while still ensuring top performance and reliability standards.

The commitment to quality is an essential aspect of Rexroth’s corporate philosophy. Each valve undergoes rigorous testing to ensure that it meets not only internal standards but also complies with international certifications. This commitment translates into products that are recognized for their reliability in critical applications where failure is not an option. Customers can trust that when they choose a Rexroth Valve, they are opting for a product that is engineered with precision and manufactured using top-quality materials.

Furthermore, the after-sales service and support provided by Rexroth enhance the value of their products. The company offers comprehensive support, including product installation and ongoing training, enabling clients to maximize their valve systems' performance. Support services aim to facilitate user understanding of proper maintenance practices, ensuring their fluid control systems function optimally over time.

Rexroth Valves represent the epitome of quality and performance in industrial applications, catering to the intricate needs of fluid control. As industries evolve with technological advancements, these valves remain a cornerstone for efficient and reliable operations. Selecting a Rexroth Valve promises a judicious investment in precision and durability, aligning closely with industry requirements and future trends. The seamless integration of innovative technologies into Rexroth's product offerings ensures that they will remain at the forefront of the fluid control market, positioning their clients for success in a rapidly changing industrial environment.

| Feature | Benefit |

|---|---|

| Precision Engineering | Ensures exact flow and pressure control for critical operations. |

| Durability | Resists wear and environmental damage, extending service life. |

| Versatility | Adapts to various applications with multiple configurations available. |

| Smart Technology Integration | Facilitates remote monitoring and predictive maintenance, optimizing efficiency. |

| Commitment to Sustainability | Promotes energy efficiency and environmental compliance, supporting green initiatives. |

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!