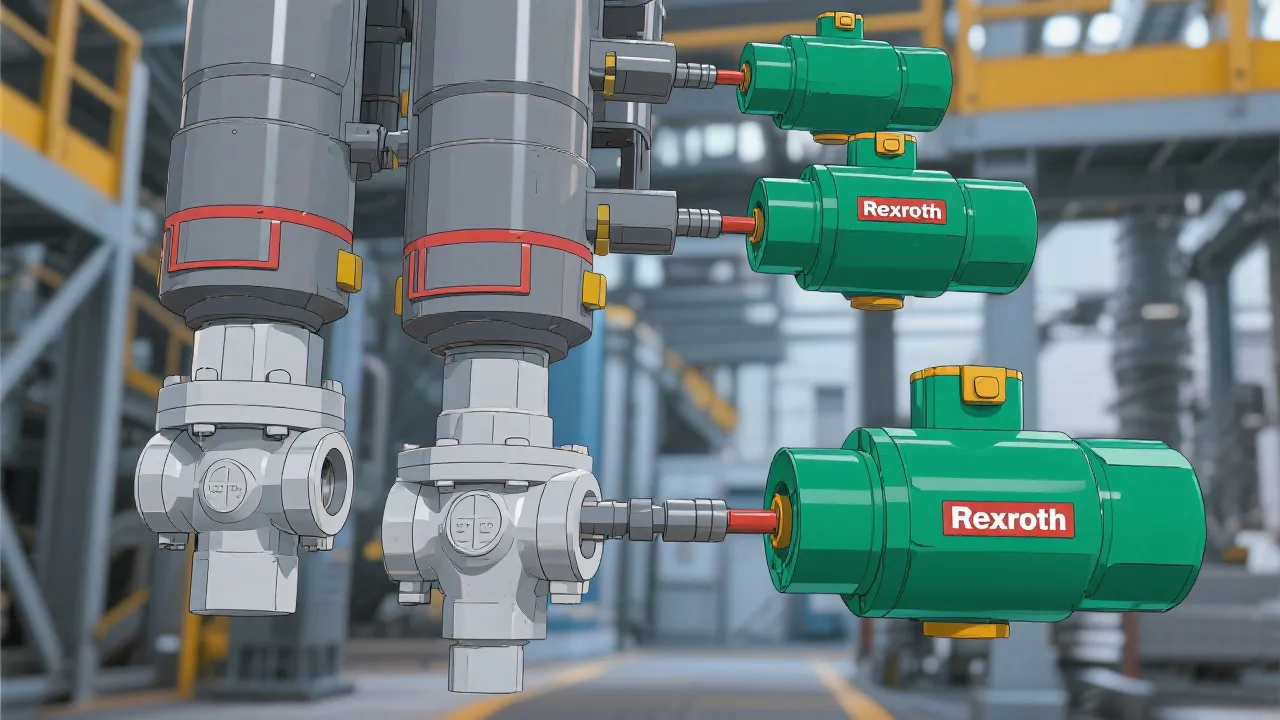

Rexroth Valves, integral components in advanced hydraulic systems, are renowned for their precision and efficiency. These valves serve diverse industrial applications, ensuring optimal flow control and system integrity. The global demand for Rexroth products highlights their pivotal role in modern machinery, underscoring the importance of understanding their functionality and advantages for industrial advancements.

Rexroth Valves are essential components widely utilized in advanced hydraulic systems across various industries. These valves are known for their reliability, precision, and efficiency, making them crucial for ensuring optimal flow control and system integrity. As industrial processes become more sophisticated, the demand for quality components like Rexroth Valves grows, reflecting their critical role in modern manufacturing and machine operations. The legacy of Rexroth as a leader in motion control technology and fluid engineering spans several decades, making their products synonymous with both quality and innovation. As we delve deeper into the various aspects of Rexroth Valves, charting their functionality, types, applications, and importance, we will uncover why they are a go-to choice for engineers and machine builders alike.

Rexroth Valves are designed to control the flow and pressure of hydraulic fluids within a system, which is essential for the precise operation of machinery. Their robust construction and advanced engineering allow them to handle extreme conditions and high pressure, making them suitable for demanding industrial applications. The versatility of Rexroth Valves makes them ideal for use in sectors such as automotive manufacturing, aerospace, heavy machinery, and many others.

At the core of their functionality is the principle of fluid dynamics, which plays a significant role in hydraulic systems. Rexroth Valves operate using principles such as Bernoulli's equation and Pascal's law, allowing them to convert hydraulic energy into mechanical energy effectively. By controlling various parameters, these valves can regulate flow rates, modulate pressure levels, and provide precise actuation for various hydraulic applications. Whether in a simple hydraulic circuit or a complex multi-valve system, Rexroth Valves ensure seamless system operations while minimizing energy loss and enhancing overall efficiency.

Understanding the different types of Rexroth Valves is fundamental for selecting the right product for specific applications. The main categories include:

Each type of Rexroth Valve serves specific functions and applications, ensuring comprehensive solutions for various operational needs. Let's explore their functionalities in more detail:

Directional valves are vital for directing hydraulic fluid to different parts of the system. They utilize mechanisms such as spools or poppets to control the routing of fluid. In industrial applications, these valves might be used in the control panels of large hydraulic presses or robotic arms, where specific actions need to be executed sequentially. The introduction of advanced technologies, such as electronic control systems, has enhanced their responsiveness and efficiency, allowing for better integration with automation systems.

Hydraulic systems often face varying load conditions that can create pressure spikes. Pressure relief valves are integral to maintaining system integrity by regulating these pressure levels. They are engineered to open at predetermined pressure thresholds, diverting excess fluid back to the tank or allowing it to bypass other sections of the circuit. This safety precaution extends the life of components, reduces maintenance demands, and safeguards operator safety. Rexroth’s high-quality relief valves are built to ensure precise set points and reliable performance.

Ensuring optimal flow rate is essential for processes that require consistent and controllable movements, such as in hydraulic lifts or conveyor systems. Rexroth's flow control valves employ adjustable orifices that modulate the flow rate based on specific application needs. These valves can be either fixed or adjustable, providing flexibility depending on operational requirements. For instance, in automotive assembly lines, controlled fluid flow can enhance cycle times and improve efficiency, contributing to increased productivity.

Proportional valves exemplify advanced hydraulic control, offering variable openings that allow for intricate flow adjustments. These valves can respond to electronic signals, enabling real-time modifications and precise movements. Applications include CNC machines or servo-driven systems, where accuracy is paramount. With features such as integrated feedback systems, proportional valves help achieve smoother operations, reduce energy consumption, and minimize wear on components, ultimately leading to lower operational costs.

Rexroth Valves find applications in various fields, underlining their adaptability and robustness:

| Type | Function | Applications |

|---|---|---|

| Directional Valve | Controls fluid path | Manufacturing, automotive, robotics |

| Pressure Relief Valve | Maintains pressure | Construction, manufacturing, aerospace |

| Flow Control Valve | Adjusts flow rate | Aerospace, manufacturing, automotive |

| Proportional Valve | Variable flow and pressure | Automotive, aerospace, CNC machines |

In any industrial application, the quality and precision of components like Rexroth Valves are paramount. Poor quality valves can lead to system failures, increased maintenance costs, and potentially harmful operational downtime. Rexroth's dedication to innovation and excellence ensures that their valves meet the highest industry standards. Their commitment to quality underlines why Rexroth Valves have become a benchmark in the hydraulic systems sector.

The manufacturing standards utilized in producing Rexroth Valves are stringent, involving rigorous testing for durability, performance, and compatibility with various hydraulic fluids. Quality control measures are in place at every production stage, from raw material selection to finished product assessments. Advanced manufacturing technologies, such as computer numerical control (CNC) machining and automated assembly processes, guarantee that each valve meets the specific requirements and expectations of end-users.

Furthermore, the precision with which Rexroth Valves operate translates into enhanced system performance. Accurate flow and pressure control lead to optimized machine operation, increasing productivity while minimizing energy consumption and operational costs. The key to achieving these efficiencies lies not only in the valves themselves but also in the complementary components within the hydraulic system. Integrating high-quality Rexroth Valves with other precision-engineered parts creates a symbiotic relationship that ultimately results in superior operational outcomes.

As industries continue to evolve, the demand for highly efficient and smart hydraulic valves is expected to grow significantly. Innovations such as IoT-enabled valves and the integration of machine learning algorithms will usher in a new era of predictive maintenance and operational efficiency. These technological advancements will allow Rexroth Valves to transmit real-time data, enabling proactive monitoring and adjustments that could lead to smarter, more optimized hydraulic systems.

The introduction of materials science advancements is also likely to impact the design and functionality of hydraulic valves. Lightweight, high-strength materials could enhance valve performance while reducing overall system weight—an essential factor in industries such as aerospace and automotive. Moreover, sustainable practices will become more prevalent, with manufacturers emphasizing components that support eco-friendly operations through reduced energy consumption and waste production.

Overall, Rexroth Valves represent a significant advancement in hydraulic system components, offering unmatched reliability and performance. As industries continue to evolve and require more sophisticated equipment, the demand for highly efficient components like Rexroth Valves is set to grow. Embracing these innovations can lead to greater system performance, reduced downtime, and enhanced productivity in a competitive industrial landscape. The continued focus on quality, precision, and technological integration positions Rexroth as a frontrunner in the hydraulic component sector, ensuring their products remain integral to future developments in industrial automation and fluid technology.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!