LVDT hydraulic valves play a crucial role in controlling the flow and pressure within hydraulic systems. These devices are integral to various applications across multiple industries due to their precision and reliability. This guide provides insight into their function, advantages, and typical usage, supplemented with expert analysis and industry insights for a comprehensive understanding of their role in modern engineering.

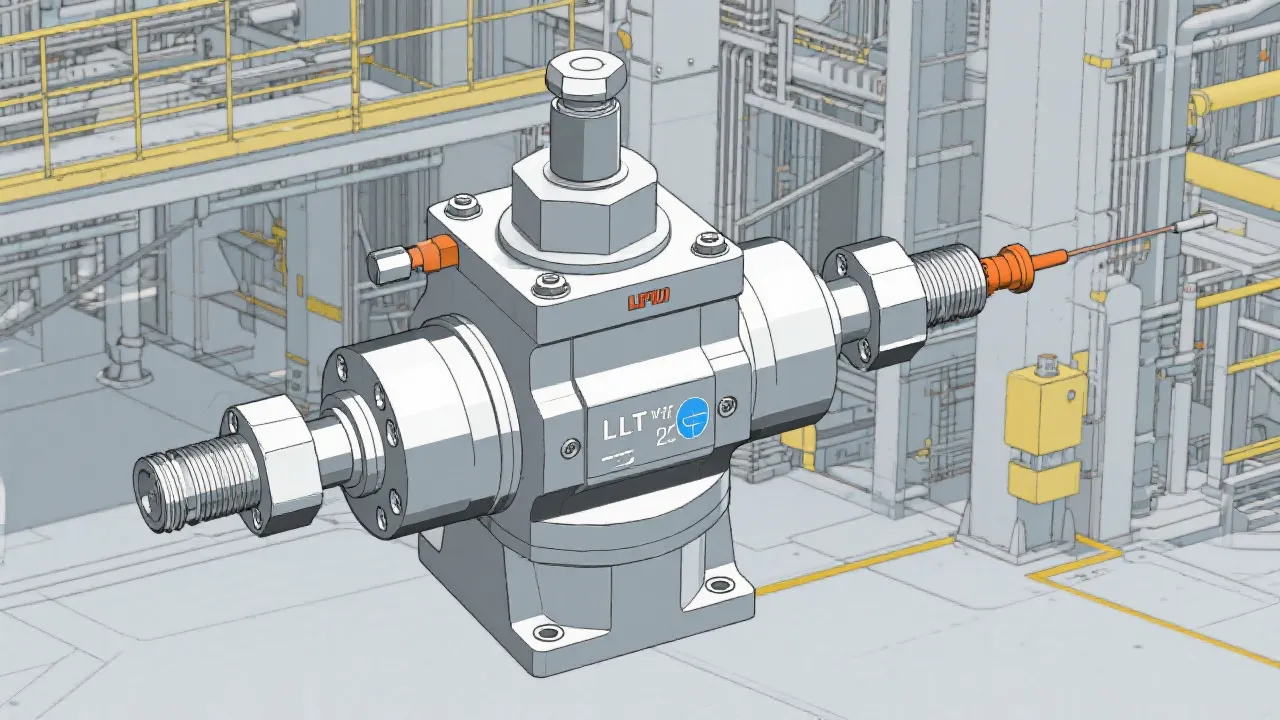

Linear Variable Differential Transformers (LVDT) hydraulic valves are an essential component in modern industrial applications. They are renowned for their accuracy in controlling fluid flow and pressure within hydraulic systems. These valves are implemented in sectors such as manufacturing, aerospace, and automotive engineering, where precise operation and reliability are paramount. Due to their advanced design and operational capabilities, LVDT hydraulic valves are at the forefront of hydraulic control technology, ensuring that machinery operates efficiently and effectively.

At the core of LVDT hydraulic valves is the Linear Variable Differential Transformer, an electromechanical device designed to convert mechanical motion into a variable electrical signal. This conversion is vital for controlling hydraulic operations accurately. The LVDT's non-contact nature ensures minimal wear and tear, leading to a longer lifespan and less frequent maintenance requirements. The LVDT operates based on the principle of electromagnetic induction, where the movement of a ferromagnetic core within the transformer alters the coupling between two primary coils and one secondary coil. This alteration results in a change in voltage, which is read as a position signal. The precise measurement of this displacement enables very fine control of hydraulic systems, ensuring that they respond appropriately to varying conditions.

The advantages of using LVDT hydraulic valves include high precision, immediate response times, and durability under extreme conditions. Due to their robust design, these valves can operate in harsh environments, resisting contaminants and maintaining optimal performance over extended periods. This makes them a reliable choice for industries that cannot afford downtime or inaccuracies. Key features that set LVDT hydraulic valves apart include:

| Feature | Benefit |

|---|---|

| High Precision | Ensures accurate control of hydraulic systems, enhancing performance in critical applications. |

| Durability | Withstands harsh conditions, reducing maintenance and operational costs. |

| Fast Response | Quick adjustments to pressure and flow, essential in dynamic environments. |

| Non-Contact Technology | Minimizes wear, leading to longer service intervals and reliability. |

These valves are utilized in a plethora of applications, from precision machining in manufacturing plants to the regulation of flight control systems in aerospace industries. In automotive engineering, they are integral to efficient engine management systems, highlighting their versatility across sectors. Key practical applications include:

The demand for LVDT hydraulic valves is steadily increasing as industries aim to enhance efficiency and reliability in their operations. With technological advancements, these valves are becoming even more integral to engineering solutions worldwide. According to a report by MarketWatch, the global hydraulic valve market is projected to grow significantly, driven by innovations in automation and robotics. As industries continue to pursue the goals of increased output and reduced operational costs, the adoption of LVDT hydraulic valves is likely to rise.

Market trends show a clear shift towards automation and smart technologies, pushing the boundaries of what hydraulic systems can achieve. Integrating LVDTs with advanced control algorithms and IoT (Internet of Things) technologies creates more intelligent systems capable of predictive maintenance, allowing businesses to schedule repairs before failures occur, thereby minimizing downtime.

When implementing LVDT hydraulic valves, several design and engineering considerations should be addressed to maximize performance and usability. Factors such as valve sizing, material selection, environment compatibility, and integration with existing systems play a vital role.

Correctly sizing LVDT hydraulic valves is crucial for ensuring that systems maintain optimal pressure and flow. Oversized valves can lead to inefficient operation while undersized valves may result in system failures. Engineers must take into account the dynamic load requirements and potential pressure fluctuations when selecting valve sizes.

The materials used in creating LVDT valves must be compatible with the fluids they will control. For example, valves operating with corrosive fluids may require specialized coatings or materials that can withstand these substances without degrading. Similarly, high-temperature applications require materials that do not weaken or deform under heat.

This includes dust, moisture, and extreme temperatures that could hinder the performance of the LVDT. Engineers might consider adding protective casings or enveloping the components in easy-to-replace filters that can capture debris without compromising the sensor's function.

While the advantages of LVDT hydraulic valves are substantial, their implementation is not devoid of challenges. Some of the factors that organizations may face include integration into existing systems, initial costs, and ongoing operator training.

The future of LVDT hydraulic valves holds great promise as technological advancements continue revolutionizing their design, functionality, and applications. Some emerging trends include:

With the advancing field of automation, LVDT hydraulic valves will likely feature more sophisticated control systems capable of self-adjusting in response to varying operational needs. This could lead to fully automated hydraulic machinery that requires minimal human interference.

The integration of IoT technologies with LVDT valves is poised to enhance their capabilities significantly. Connected systems can provide real-time data analysis, enabling predictive maintenance and providing insights into system efficiencies that were previously impossible to achieve.

Ongoing research into advanced materials will likely yield more durable and lightweight valve constructions. Innovations such as 3D printing could also revolutionize how these valves are manufactured, allowing for complex designs and quicker prototyping.

As the use of LVDT hydraulic valves grows in importance, industry standards and regulations are evolving to ensure safety and reliability. Organizations must remain compliant with regulations set by bodies such as the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO). Compliance involves thorough testing and certification processes to ensure that valves meet stringent performance and safety benchmarks.

With the heightened focus on environmental sustainability, hydraulic systems incorporating LVDT valves must also consider their ecological footprint. Innovations aimed at reducing oil leakage, improving fuel efficiency, and recycling used hydraulic fluids are becoming essential sustainability measures in hydraulic engineering. Manufacturers are being urged to adopt greener practices and materials that minimize their environmental impact while maintaining performance efficiencies.

LVDT hydraulic valves represent a pinnacle of engineering precision, serving critical roles in numerous industries. Their ability to reliably control hydraulic functions under demanding conditions underscores their importance in modern industrial applications. As technology progresses, the capabilities and applications of these valves are expected to expand, continuing to drive efficiency and innovation across various fields. A future imbued with advancements in automation, smart technologies, and sustainable practices will further emphasize the transformative potential of LVDT hydraulic valves, establishing them as central components for developing next-generation hydraulic systems.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!