This guide delves into the intricate workings and applications of the Rexroth Poppet Valve, a vital component in hydraulic systems. Known for its robustness and efficiency, the Rexroth Poppet Valve plays a crucial role in managing fluid flow within various industrial settings. The article explores its design, functionality, and advantages, providing a comprehensive understanding from an expert's perspective.

The Rexroth Poppet Valve stands as a cornerstone in the realm of hydraulic systems. Known for its robust build and efficient performance, this valve type is an integral component in various industrial applications. As the industry advances towards more sophisticated technology, understanding the dynamics and functionalities of such a key element becomes imperative for professionals and enthusiasts alike. An insight into Rexroth's rich history reveals its roots in precision engineering, which has helped establish its reputation for quality and innovation in hydraulic solutions.

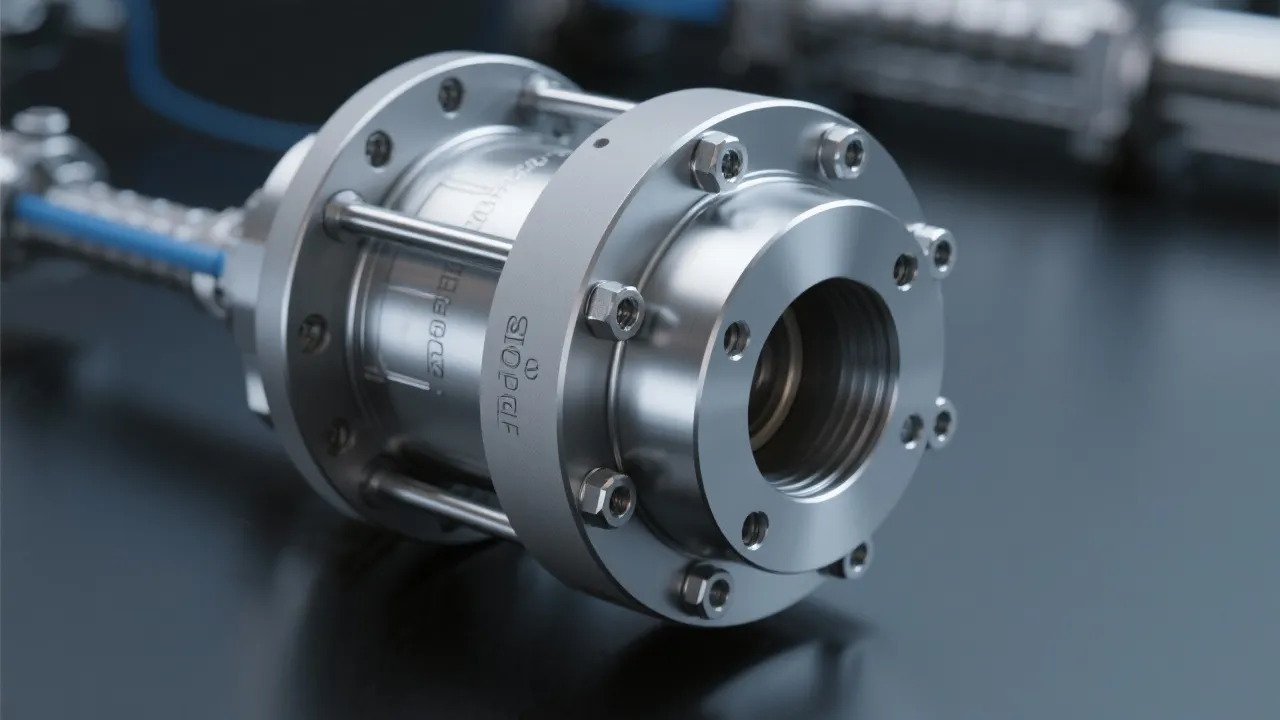

The design of the Rexroth Poppet Valve is anchored in simplicity yet offers high reliability. It operates on the principle of allowing or preventing flow through the movement of a poppet, which is pressed against a valve seat. This movement is typically actuated mechanically or by a combination of hydraulics and electronics, adding to its versatility in applications ranging from simple mechanical systems to complex automated processes.

Rexroth has engineered these valves to withstand demanding conditions, ensuring durability and minimal leakage. The precision in manufacturing supports a tight seal, crucial for maintaining system pressure and efficiency. Furthermore, the material choices in constructing the valve—such as hardened steel or specialized alloys—are significant in extending operational life by preventing wear and tear caused by corrosive substances or high-pressure conditions. A good understanding of these materials and their properties can enhance the selection process for applications that require specific performance characteristics.

The mechanism of a Rexroth Poppet Valve is fascinating; it can be viewed as a simple yet elegant solution to fluid control. At its core, the valve consists of a valve body, a poppet, and a seat. When the hydraulic pressure activates the actuator, it moves the poppet away from the seat, allowing fluid to flow through the valve. Conversely, when the actuator is deactivated, the poppet returns to the seat, ceasing the flow.

This push-pull action requires a fine balance between the springs and the hydraulic forces acting upon it, necessitating meticulous engineering to ensure reliability. For practical applications, users must select the appropriate spring stiffness and actuator power requirements to guarantee effective operation under various system pressures.

Industries relying heavily on hydraulic systems often prefer the Rexroth Poppet Valve due to its adaptability in managing various fluid dynamics. Its common applications include but are not limited to, automotive manufacturing, aerospace hydraulics, and heavy machinery. This variety of uses underscores the valve's ability to process high volumes of fluid under significant pressure, maintaining consistent performance across diverse environments.

In automotive manufacturing, for instance, Rexroth Poppet Valves are utilized in systems for power steering, brake controls, and hydraulic actuation systems, ensuring responsiveness and safety in vehicle handling. The aerospace industry, requiring strict adherence to safety standards, utilizes these valves for flight control surfaces, landing gears, and hydraulic systems due to their reliability and precise control.

Moreover, in construction and earth-moving equipment, the valves are instrumental in controlling hydraulic lifts, allowing for efficient movement and stability. This versatility speaks to the inherent design quality that accommodates the variances in pressure and flow dynamics demanded across various sectors.

One of the primary advantages of the Rexroth Poppet Valve is its minimal internal leakage, contributing to greater operational efficiency. The design also favors quick response times—measured in milliseconds—which are essential for applications requiring rapid actuation. These valves are engineered to handle substantial flow rates and are resistant to contamination within the hydraulic fluid, offering longevity and reliability unmatched by some alternative valve configurations. For industries where precision is crucial, these features reduce the risk of system failures and downtime, ultimately translating to cost savings.

Additionally, the lightweight nature of certain Rexroth Poppet Valves makes them attractive for mobile applications. Engineers often look for ways to minimize the weight and bulk of components without sacrificing durability or performance. The combination of advanced materials and innovative design provides a competitive edge in performance-critical environments such as automotive racing and aerospace, where every gram counts.

| Feature | Benefit |

|---|---|

| Tight Sealing | Prevents leaks and maintains pressure effectively. |

| Quick Response | Ensures efficient operation in dynamic environments. |

| Durability | Withstands high pressures and tough conditions. |

| Versatility | Adapts to a wide range of industrial applications. |

| Low Maintenance | Requires less frequent servicing, reducing downtime. |

| Contamination Resistance | Maintains fluid purity and system performance over time. |

As industries push towards automation and efficiency, the evolution of the Rexroth Poppet Valve is inevitable. Future innovations may include integration with IoT technologies for predictive maintenance and advanced material use to further enhance durability and reduce weight. These developments aim to improve operational efficiencies and reduce downtime, offering a competitive edge in the fast-paced world of industrial hydraulics.

Moreover, automation and the incorporation of artificial intelligence will likely enhance the responsiveness and predictability of the Poppet Valve's operation. Smart valves could analyze data from hydraulic systems in real time, allowing operators to make informed decisions about maintenance schedules, identify issues before they escalate into costly repairs, or reconfigure system parameters for optimal performance.

While the Rexroth Poppet Valve offers several advantages, it is not without its challenges. One key consideration is the installation and maintenance process, which requires skilled technicians who can understand the complexities of hydraulic systems. The initial setup could demand significant time and resources, particularly in larger installations with multiple valves working in synchronization.

Moreover, the compatibility of hydraulic fluids must be closely monitored; using non-approved fluids could lead to accelerated wear or even catastrophic failure. Engineers must also consider the temperature range within which the valves will operate, as extreme temperatures could affect valve performance and longevity. The selection of the appropriate valve and its components, including seals and actuators, is crucial for ensuring the intended performance in these conditions.

The Rexroth Poppet Valve's distinctiveness lies in its precise design offering minimal leakage and high-pressure handling capabilities, essential for efficient hydraulic systems. Unlike other valve types, such as spool valves, the poppet valve's simple mechanism provides a straightforward and reliable solution for many applications.

Minimal internal leakage ensures that the system maintains maximum pressure, enhancing efficiency and reducing energy consumption, which is critical in power-intensive operations. This is vital not only for economic performance but also for preserving the integrity of hydraulic circuits where consistent performance is non-negotiable.

The valves are designed for quick actuation and adaptability, which helps in maintaining optimal flow rates and pressure levels, pivotal for efficient hydraulic system performance. In high-speed applications, the ability to minimize response times directly influences productivity and operational capabilities.

Industries such as automotive, aerospace, construction, agriculture, and manufacturing benefit significantly from using Rexroth Poppet Valves. Each of these sectors relies on hydraulic systems for varied applications, from managing large hydraulic presses to controlling advanced robotic movements.

Selecting the right valve involves evaluating your system's pressure, flow rate, and fluid type. Consider consulting with a hydraulic systems engineer to assess your specific needs, ensuring compatibility and optimal performance.

In conclusion, the Rexroth Poppet Valve represents a blend of time-tested reliability and modern engineering advancements, making it a crucial component in the hydraulic systems industry. Its unique functionality, durability, and versatility appeal widely across diverse applications, establishing it as a preferred choice among engineers and manufacturers. As innovations continue to emerge, its role remains significant, providing the backbone for efficient and durable fluid control solutions.

For individuals looking to dive deeper into the world of Rexroth Poppet Valves and hydraulic systems, various resources are available. Books on fluid power engineering provide foundational knowledge about hydraulic circuits and valve operations. Additionally, online courses and webinars hosted by industry professionals can offer insights into best practices for design and maintenance of hydraulic systems.

Moreover, attending industry trade shows and conferences can prove beneficial for networking and witnessing firsthand the latest advancements in hydraulic technology. Engaging with the community through forums and professional associations often sheds light on real-world applications and case studies, enhancing one’s understanding of the Poppet Valve's role in modern industry.

Several case studies illustrate the practical applications of Rexroth Poppet Valves. One notable case in automotive manufacturing demonstrated how implementing Rexroth Valves in a robotic assembly line increased the precision and speed of operation. By utilizing these valves for controlling the hydraulics in robotic arms, the manufacturing facility reported a notable increase in throughput without compromising on safety or quality.

In another example, a construction equipment manufacturer incorporated Rexroth Poppet Valves into their hydraulic excavators. The result was improved stability and reliability when handling heavy loads. The valves contributed to a more responsive hydraulic system, allowing the machinery to operate efficiently across various terrains, which is critical in construction settings where conditions frequently change.

Such case studies not only highlight the effectiveness of the Rexroth Poppet Valve but also showcase the importance of selecting the right components to meet the specific demands of various industrial applications. As industries continue to evolve, these valves will likely remain at the forefront of hydraulic technology innovation.

To summarize, the Rexroth Poppet Valve is integral to modern hydraulic systems, characterized by its durability, reliability, and efficiency. Its ability to handle high-pressure environments with minimal leakage sets it apart from competing technologies. As the industry continues to integrate more advanced technologies, Rexroth is poised to be a leader in hydraulic solutions that not only meets present demands but anticipates future challenges.

Understanding the nuances of hydraulic systems, including the specific role of the Rexroth Poppet Valve, is essential for professionals in various fields. Awareness of ongoing innovations and potential applications can empower engineers and decision-makers to make informed choices that align with their organization's strategic objectives. Ultimately, the continued advancement in hydraulic technologies promises to further enhance the capabilities of the Rexroth Poppet Valve, ensuring its relevance and importance in the ever-evolving industrial landscape.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!