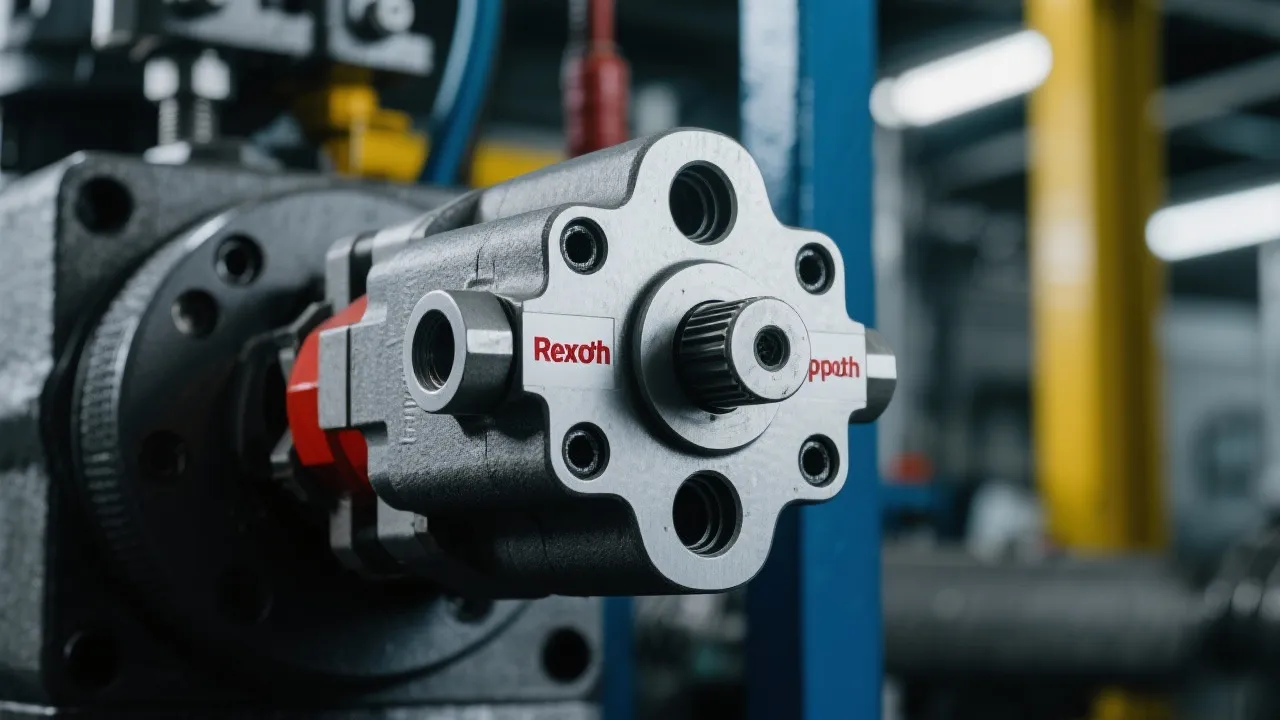

This comprehensive guide provides an in-depth analysis of Rexroth poppet valves, a crucial component in various industrial hydraulic systems responsible for controlling fluid flow and pressure. Highlighting their design, functionality, and applications, this article seeks to enlighten readers about the essential role these valves play in industrial operations, with insights into their benefits and maintenance needs.

The Rexroth poppet valve is a quintessential device in hydraulic systems, crucial for the efficient control of fluid flow and pressure. Known for their durability and precision, these valves are extensively employed across numerous industrial sectors. Whether in manufacturing plants, construction machinery, or automotive systems, their role remains indispensable. The evolution of hydraulic systems over the years has been significantly supported by the reliable functioning of poppet valves, which can handle various operating conditions and ensure safety and efficiency.

Poppet valves operate on a simple yet effective principle. They consist of a movable poppet, which seals against a valve seat to control fluid flow. When actuated, the poppet moves away from the seat, allowing the fluid to pass through. This action can be initiated by various mechanisms, including electric signals, hydraulic pressure, or pneumatic energy. Their design ensures a leak-affordable operation, making them an ideal choice for environments requiring high precision and control. The sealing capability of the poppet against the valve seat ensures minimal hydraulic losses during operation, which is critical for maintaining efficiency in hydraulic circuits.

Rexroth's poppet valves are celebrated for several key features:

Rexroth poppet valves find applications in numerous sectors:

Regular maintenance of poppet valves is paramount for ensuring optimal performance. A well-maintained poppet valve not only extends its lifespan but also boosts the overall performance of hydraulic systems:

| Maintenance Step | Description |

|---|---|

| Inspection | Check for visible signs of wear or damage, focusing on the valve body and any actuator mechanisms. |

| Cleaning | Remove debris and ensure the valve seat is clear to facilitate unobstructed fluid flow. |

| Lubrication | Apply appropriate lubricant to moving parts, following manufacturer specifications to avoid introducing incompatible materials. |

| Seal Replacement | Replace any worn or damaged seals promptly to prevent leaks and maintain system integrity. |

The primary advantage is their precise control of fluid flow with minimal leakage, ensuring reliability in high-pressure environments. Their efficient sealing mechanism is beneficial in applications where fluid conservation is critical.

Regular monthly inspections and cleaning are recommended, with comprehensive maintenance bi-annually. In high-usage scenarios, more frequent inspections may be warranted.

Yes, they are versatile enough to function efficiently in a wide range of pressure settings. The design specifics of the valve can be tailored to the intended application, whether it be high-pressure hydraulics or lower pressure applications.

They are typically manufactured from materials such as steel, aluminum, and specialized composites, chosen to offer the best balance of strength, weight, and resistance to environmental factors. The choice of material impacts the durability and performance of the valve.

Yes, many modern poppet valves can be integrated with electronic control systems to allow for more precise control and automation. This capability is increasingly important in industries seeking to enhance operational efficiency through automation.

Rexroth poppet valves are a pivotal component in industrial hydraulic systems, known for their efficiency, durability, and precision. By understanding their operation, key features, and maintenance requirements, industries can ensure these valves perform optimally. Integrating Rexroth poppet valves into hydraulic systems promises enhanced control and reliability, crucial for any sector dependent on fluid power systems. Furthermore, the ongoing advances in valve technology, including smart integration and improved materials, present exciting opportunities for increasing performance and efficiency in future applications. As industries evolve and adapt to new challenges, the role of reliable poppet valves becomes even more critical, solidifying their place in modern hydraulics.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!