Eaton Proportional Valves are pivotal components in fluid power control systems, providing precise control of fluid flow and pressure. These valves are crucial in various industries, from agriculture to aerospace, enhancing system efficiency and performance. They harness the power of electronic control to adjust flow rates to desired levels, ensuring optimal operation tailored to specific applications.

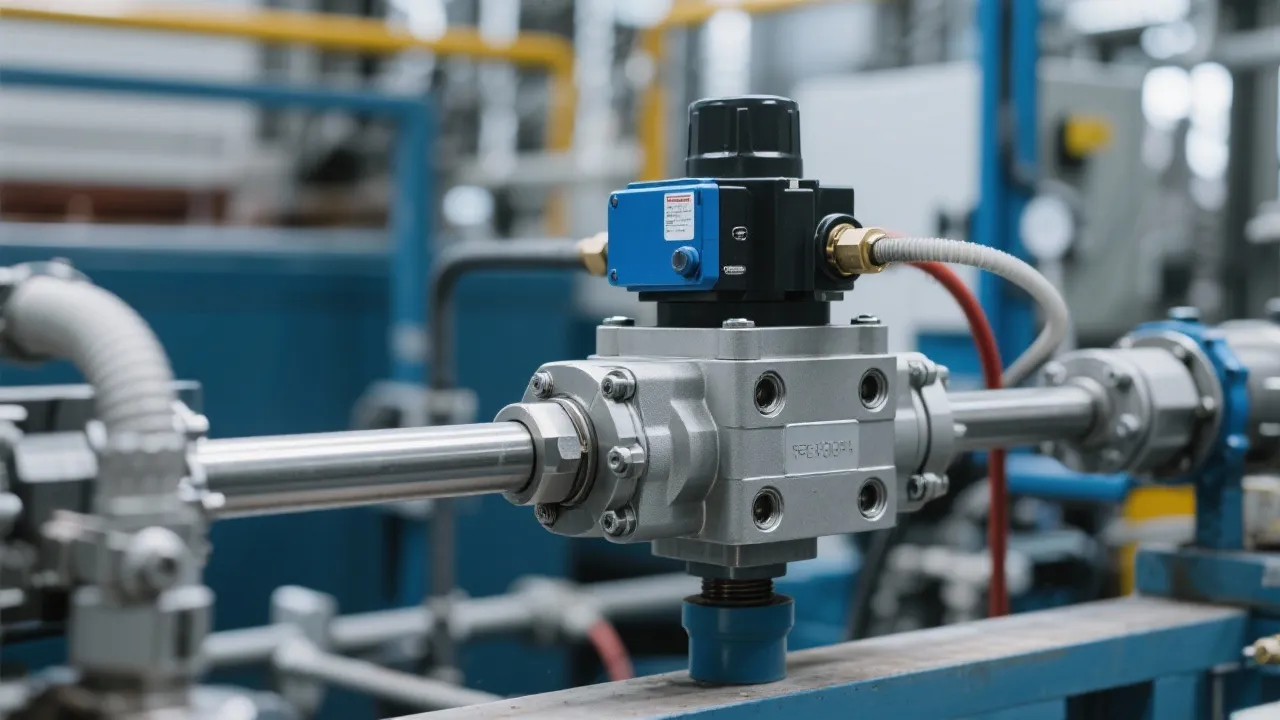

Eaton Proportional Valves stand at the forefront of fluid control systems, renowned for their precision, reliability, and adaptability. These valves are designed to modulate flow or pressure in hydraulic systems, making them indispensable in various industrial applications like manufacturing, aerospace, and automotive sectors. By providing real-time adjustments through electronic signals, these valves offer unparalleled control and efficiency. The sophisticated design allows these valves to interpret signals from various sources, including sensors and controllers, facilitating a responsive adjustment to the system's needs.

The core function of Eaton Proportional Valves lies in their ability to adjust the hydraulic output based on an input signal, usually from a programmable logic controller (PLC). As the input signal varies, the valve position changes, thereby altering the flow or pressure to match system requirements. This dynamic response capability is what elevates proportional valves above standard valves, which operate merely in open or closed states. Moreover, the linear or rotary movements of these valves correlate directly with the input signals, enabling an intuitive adjustment to output parameters without unnecessary delays. This responsiveness is crucial in applications where timing and precision are vital.

From the high-precision demands of the aerospace industry to the robust requirements of heavy machinery in construction, Eaton Proportional Valves provide solutions across different verticals:

Implementing Eaton Proportional Valves brings a spectrum of advantages:

Integrating an Eaton Proportional Valve into a hydraulic system involves several key steps:

| Model | Flow Rate (l/min) | Pressure Range (bar) | Application |

|---|---|---|---|

| Eaton PVH | 60-360 | 250-350 | Mobile Machinery |

| Eaton Vickers | 20-100 | 200-300 | Industrial Automation |

| Eaton DS | 10-40 | 150-250 | Construction Equipment |

| Eaton M-Series | 5-25 | 100-250 | Aerospace |

| Eaton X-Track | 30-80 | 200-300 | Automotive Systems |

Q1: What is the main advantage of using Eaton Proportional Valves?

A1: The primary advantage is the ability to precisely control fluid flow and pressure, resulting in improved system performance and efficiency. This precision enables industries to optimize operational processes significantly, thus contributing to overall productivity.

Q2: Are these valves suitable for all types of hydraulic systems?

A2: Eaton Proportional Valves are versatile and can be adapted for use in various hydraulic systems, but it is essential to match the valve specifications to the system requirements to avoid compatibility issues.

Q3: How do I ensure the longevity of these valves?

A3: Regular maintenance, such as cleaning and lubrication, along with periodic system checks, can greatly enhance the life span of the valves. Implementing a routine maintenance schedule that includes inspecting seals and connections, as well as checking for signs of wear, will help prevent potential failures before they occur.

Q4: Can Eaton Proportional Valves be used in high-temperature applications?

A4: Yes, but it depends on the specific materials of construction and the rated temperature limits of the valve model being used. Ensure to consult the product specifications to verify the suitability for high-temperature applications.

Q5: What is the role of electronics in Eaton Proportional Valves?

A5: Electronics are critical for controlling the valve's position and output based on input signals. They allow for sophisticated control algorithms that enable smooth and precise adjustments in real time, which is essential in automated systems.

Eaton Proportional Valves represent a significant advancement in hydraulic control technology, providing not just operational improvements but also contributing to the longevity of the systems they integrate with. The ability to modulate flow and pressure dynamically makes these valves invaluable in enhancing performance across various applications. Whether through their application in industrial automation or high-tech aerospace systems, understanding and leveraging these valves can unlock new levels of efficiency and performance. As industries continue to evolve and demand higher efficiencies, Eaton Proportional Valves will undoubtedly remain a cornerstone of hydraulic technology, adapting to meet the challenges of future engineering demands.

The future of Eaton Proportional Valves looks promising, with ongoing advancements in technology poised to enhance their functionality further. As industries increasingly adopt Industry 4.0 principles, there is growing interest in integrating proportional valves with IoT (Internet of Things) devices. This integration would allow for improved data collection and analysis, feeding into predictive maintenance models, thereby reducing downtime and enhancing operational efficiency.

Moreover, with sustainability gaining more prominence in industrial designs, Eaton Proportional Valves are expected to play a pivotal role in energy-efficient systems. Their ability to optimize hydraulic operations aligns perfectly with the goal of reducing energy consumption and greenhouse gas emissions. Features such as low power electronics and innovative materials will likely be developed to create even more efficient hydraulic components.

In addition, the demand for proportional valves in sectors like renewable energy, including wind and solar power generation, is likely to increase. These applications require highly reliable and efficient fluid control solutions for hydraulic systems used in turbine operation and tracking mechanisms. Eaton's traditional strengths in this area suggest they will be at the forefront of developing tailored solutions for such emerging applications.

Finally, results from various research initiatives focusing on materials science and electronic control systems suggest that Eaton Proportional Valves may also evolve to become “smart” components. This transition to smart fluid control could mark a new era of automation whereby valves can self-calibrate and communicate performance data autonomously, leading to significantly enhanced reliability and performance.

In conclusion, Eaton Proportional Valves not only represent an essential tool for mastering fluid control today but are also paved with remarkable potential for future developments. As technology continues to advance, industries that leverage these innovations will hold a distinct competitive advantage, ensuring Eaton Proportional Valves remain a staple fixture in hydraulic systems across numerous applications.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!