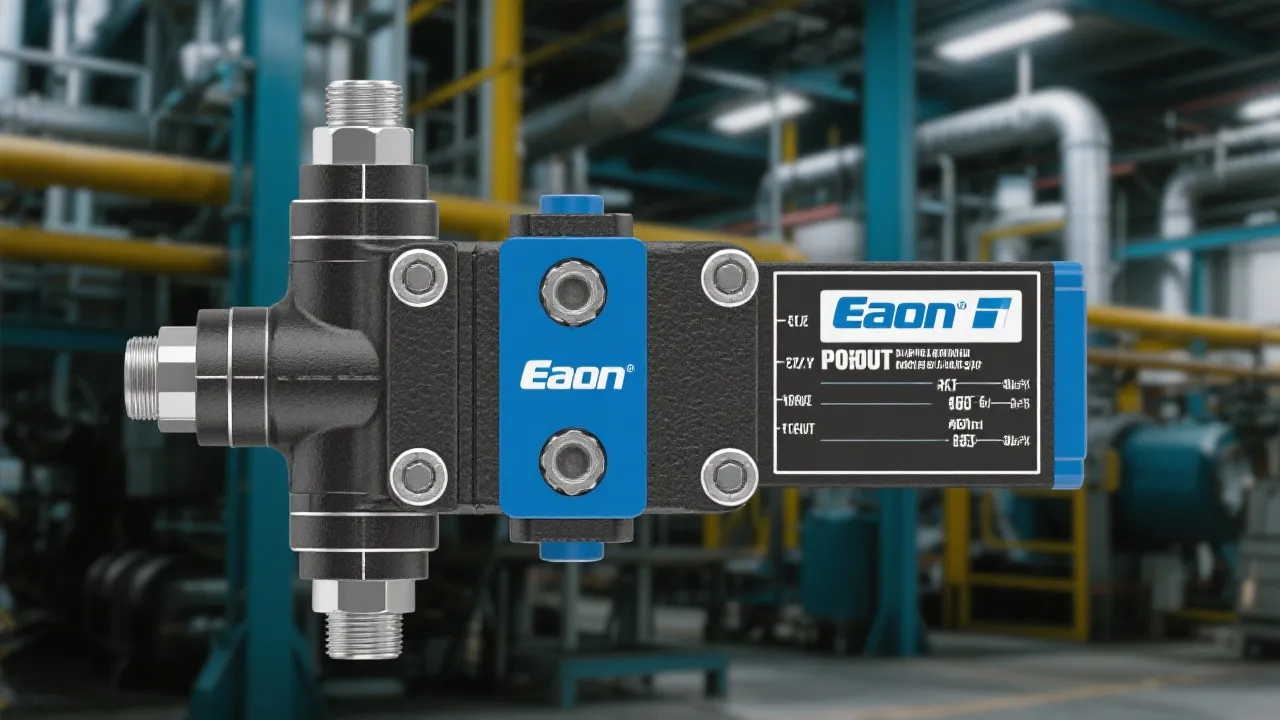

The Eaton Proportional Valve stands out in fluid power systems for its precision and efficiency. This article delves into the operation, applications, and benefits of using these valves. Known for their exceptional control in flow and pressure, Eaton Proportional Valves are integral to modern hydraulic systems, providing solutions that enhance system performance and reliability across various industries.

In the realm of fluid power systems, Eaton Proportional Valves are synonymous with advanced technology and reliable performance. These valves are engineered to precisely control flow and pressure within hydraulic systems, playing a critical role in enhancing the efficiency and responsiveness of the machinery they support. As industries evolve and demand more sophisticated machinery capable of handling complex tasks, the role of these valves becomes even more significant. Their ability to offer adaptive control means they are essential in maintaining the operational efficiency of modern industrial systems.

Proportional valves allow for variable fluid flow and directional control, which is essential in applications requiring smooth operation and accurate positioning. Compared to traditional valves, proportional valves provide a finer degree of control, adapting to varying system demands with enhanced precision. This granular control allows for improved operational parameters, enabling machinery to perform with greater sensitivity to changes in load, speed, and pressure.

These valves are often equipped with integrated electronics and sensors that facilitate real-time feedback and adjustment, significantly improving the adaptability of hydraulic systems in industries such as manufacturing, automotive, and aerospace. By continuously monitoring system performance, Eaton Proportional Valves adjust their operations dynamically, ensuring optimal functionality. This level of automation not only enhances performance but also contributes to improved safety and reduced risk of failure in high-stakes environments.

Eaton's design prioritizes innovation and reliability. The valves are crafted to withstand diverse operational environments, thanks to their robust construction and advanced materials. Here are some notable features:

Eaton Proportional Valves are utilized in numerous sectors due to their flexibility and control capabilities. Here are a few examples:

When selecting an Eaton Proportional Valve, it's crucial to assess several technical specifications that determine its suitability for specific applications. These include:

The global market for hydraulic components, including proportional valves, reflects steady growth as industries increasingly seek automation and advanced control solutions. The demand for high-performance, reliable components is influenced by the rise of smart manufacturing and IoT systems, where data-driven decision-making is crucial. As a result, suppliers who can offer advanced technological solutions and responsive service have a competitive edge in this evolving landscape.

With the increasing emphasis on automation, the demand for Eaton Proportional Valves is expected to continue its upward trajectory. Factoring in sustainability considerations, many manufacturers are looking for efficient systems that not only improve productivity but also reduce environmental impact. Hydraulic systems integrated with energy-saving features are essential in meeting these new challenges.

For businesses seeking enhanced operational control, efficiency, and reliability, Eaton Proportional Valves offer an outstanding solution. Choosing the right valve not only optimizes current operations but also secures a scalable and adaptable path for future growth. The emphasis on integrated solutions in modern industries means that systems utilizing Eaton Proportional Valves can easily evolve alongside technological advancements.

In the pursuit of industrial innovation, selecting components like the Eaton Proportional Valve is a testament to a commitment to excellence. The long-term benefits of investing in high-quality hydraulic components manifest through improved system performance, reduced downtime, and cost savings, all of which contribute to a stronger competitive edge in today’s market.

As we look ahead, the development of Eaton Proportional Valves will likely be influenced by several trends shaping the hydraulic component industry. Here are some significant advancements to expect:

In closing, the importance of Eaton Proportional Valves within the context of modern hydraulic systems cannot be overstated. As industries grapple with increasing complexities and stringent performance demands, these valves stand out as a beacon of resilience and technological excellence. By choosing Eaton, businesses are not just investing in a product; they are investing in a comprehensive solution designed to tackle the challenges of today and tomorrow.

Embracing the future of hydraulic systems with Eaton Proportional Valves means aligning with a partner that values precision, efficiency, and innovation. As businesses aim to remain competitive in an ever-evolving marketplace, Eaton’s commitment to delivering high-quality hydraulic components ensures they are well-equipped to meet the demands of the future.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!