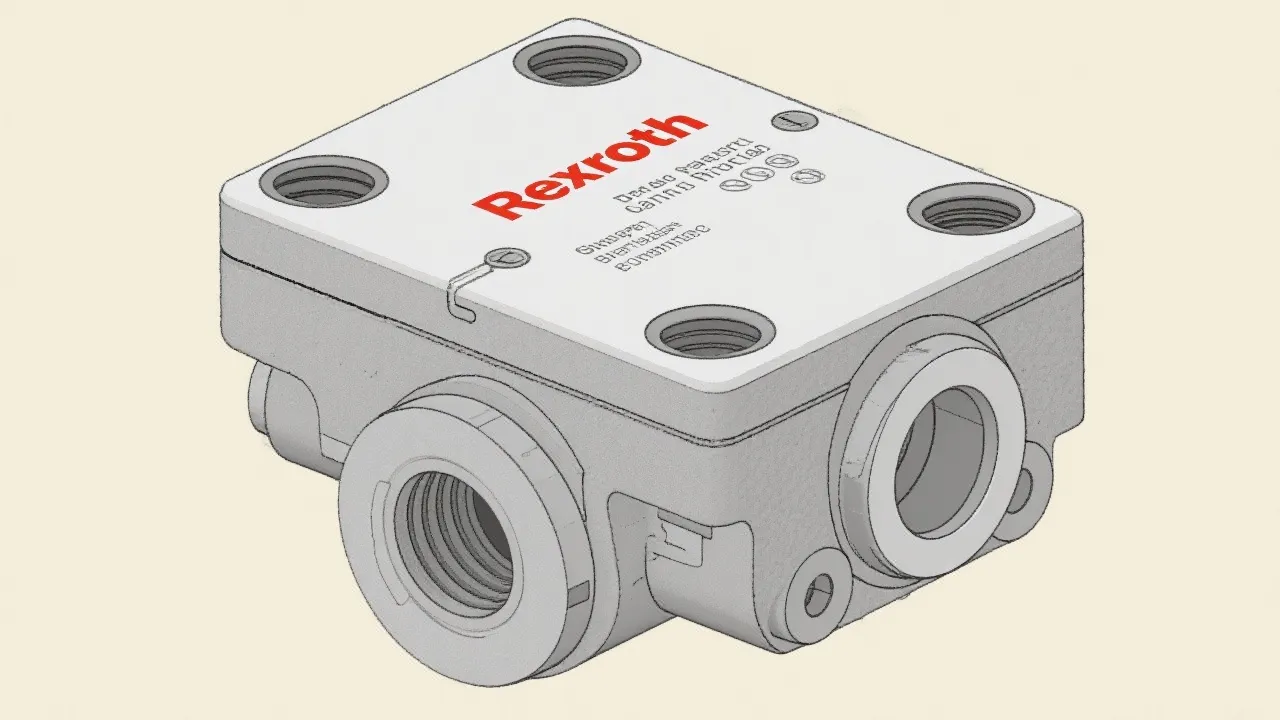

Rexroth Counterbalance Valves are pivotal components in hydraulic systems used to maintain controlled descent and prevent load runaway in various industrial applications. These valves excel in maintaining pressure balance and ensuring safety and precision in machinery operations. This article explores the intricacies of Rexroth Counterbalance Valves, their functionality, applications, and their role in enhancing industrial efficiency and safety.

The Rexroth Counterbalance Valve is a vital hydraulic component designed to control the force and movement in machinery efficiently. These valves are highly respected in the industry for their ability to maintain pressure balance within hydraulic systems, thereby preventing uncontrolled descents and ensuring smooth operation of industrial machinery. Given their importance, understanding these valves' functionality and applications is crucial for mechanical engineering and automation professionals. The design and appropriate application of these valves can significantly enhance operational safety, reliability, and performance in various applications, making them indispensable in modern hydraulic engineering.

Rexroth Counterbalance Valves function as safety mechanisms within hydraulic systems. Their primary role is to control the pressure applied on hydraulic actuators, maintaining a balance that prevents load runaway. This is especially critical in load handling equipment like cranes, where the dangers of incorrectly regulated pressure could result in equipment failure or accidents. By automatically adjusting pressure based on the load's demands, these valves ensure the machinery operates safely and effectively. The ability to monitor and react to changes in hydraulic pressure makes these valves essential components in dynamic load scenarios.

Moreover, the Rexroth Counterbalance Valves also provide a form of energy efficiency. When handling loads, these valves can reduce unnecessary hydraulic power consumption by minimizing the energy required to control movements, resulting in lower operational costs and increased overall system efficiency. Their design incorporates features that allow for fast response times, which is critical in applications involving rapid load movements. Overall, the integration of counterbalance valves in hydraulic systems not only enhances safety but also improves the overall performance and operational longevity of machinery.

These valves are widely used across various industries wherever hydraulic systems play a crucial role. Industrial machinery such as lifting platforms, cranes, and tractors benefits significantly from installing Rexroth Counterbalance Valves. Their capacity to provide precise control makes them indispensable in settings where safety and efficiency are paramount. For instance, in construction, cranes rely on counterbalance valves to manage heavy loads safely and ensure that movements are controlled during lifting and lowering operations. Without these valves, the risk of sudden drops or uncontrolled movements could lead to catastrophic incidents, emphasizing their critical role in safeguarding personnel and equipment alike.

In the manufacturing sector, automated machinery such as robotic arms and assembly lines often utilize counterbalance valves to maintain consistent pressure across various operations. This consistency ensures that tasks are performed without unexpected delays or failures, ultimately improving production rates and maintaining product quality. In agriculture, tractors equipped with these valves can manage implements that require precise control during operation, safeguarding against equipment damage and enhancing operational efficiency. Thus, the versatility of Rexroth Counterbalance Valves allows them to serve a broad spectrum of applications, underpinning their necessity in today’s advanced industrial processes.

Rexroth Counterbalance Valves are crafted with precision to suit a range of operational pressures and flow rates. Typically, they are available in various configurations that cater to different hydraulic systems' needs. These specifications include adjustable pressure settings and flow regulation adjustments, allowing for customization based on specific machinery requirements. Understanding these technical details is crucial for professionals tasked with installing or maintaining these hydraulic components.

The valves are designed to operate effectively under varying conditions, maintaining their functionality despite fluctuations in load and environmental factors. They usually come equipped with features such as:

This customization capability is particularly beneficial in applications requiring precise control over heavy loads or rapid operational changes. For example, in applications where multiple loads are operated concurrently, the flexibility in configuration allows for individual adjustments that enhance overall system stability and functionality. Operators benefit from these detailed specifications by being able to tailor valve performance to meet unique operational challenges, significantly improving efficiency and response times in hydraulic systems.

When comparing Rexroth Counterbalance Valves to other types of hydraulic valves, such as check valves or relief valves, several distinctions stand out. Counterbalance valves are specifically engineered to handle the dynamic control of loads, which involves reacting to fluctuations in pressure and load weight. This makes them superior in applications where load control and safety are paramount compared to check valves that primarily prevent backflow or relief valves that merely safeguard against excess pressure.

Significantly, counterbalance valves are pivotal in dynamic systems where pressure, load, and movement vary. They help manage not only the safety of the operations but also the efficiency by ensuring that hydraulic energy is used optimally to control loads without wastage. This contrasts sharply with general-purpose check valves, which are often limited to single-direction flow regulation without any feedback mechanisms to adapt to changing pressures and velocities.

| Feature | Rexroth Counterbalance Valve | Standard Relief Valve |

|---|---|---|

| Primary Use | Load holding and descent control | Pressure regulation |

| Response to Load | Automatically adjusts based on load demands | Fixed pressure response |

| Safety | High level of safety for load handling | Basic safety against pressure peaks |

| Applications | Lifting platforms, cranes, industrial machines | General hydraulic systems |

In scenarios where precise load handling is necessary, such as in mobile applications or equipment with variable load specifications, the counterbalance valve excels by offering superior performance over conventional relief systems. This elevated level of functionality ensures that equipment operates within safe parameters, enhancing overall operational safety and extending the life cycle of the hydraulic components used.

What is the purpose of a counterbalance valve?

Counterbalance valves are used to maintain controlled descent and prevent uncontrolled loads in hydraulic systems, ensuring operational safety and efficiency.

How do Rexroth Counterbalance Valves enhance safety?

These valves prevent load runaway by maintaining the pressure balance within hydraulic systems, thus ensuring the safe operation of machinery. By dynamically adjusting to the weight of the load being handled, they mitigate the risks associated with sudden drops or loss of control, preserving both equipment integrity and operator safety.

Are Rexroth Counterbalance Valves customizable?

Yes, they are available in different configurations with adjustable settings to fit various industrial applications and machinery specifications. This adaptability ensures that they can function effectively across a wide range of operational contexts, allowing engineers to fine-tune performance features to meet specific requirements.

Why choose Rexroth over other brands?

Rexroth is renowned for its precision engineering and reliability, offering superior performance in high-stakes industrial environments. The brand’s commitment to quality, innovation, and customer support ensures that their products meet the highest standards, providing peace of mind to operators and engineers working with complex hydraulic systems.

How do Rexroth Counterbalance Valves contribute to energy efficiency?

By optimizing the use of hydraulic pressure and acting responsively to load changes, these valves can significantly reduce the energy consumption required to operate machinery. This leads to lower operational costs, improved sustainability, and a reduced environmental impact associated with hydraulic system operations.

In conclusion, the Rexroth Counterbalance Valve is a cornerstone of hydraulic system safety and efficiency, serving diverse industries that rely on precise pressure control and load management. Understanding its operation, applications, and advantages will significantly benefit professionals involved in the maintenance and deployment of hydraulic systems. The decision to implement these valves can often determine not just operational success but also impact the overall safety standards observed in various industrial environments. By embracing technology such as Rexroth's counterbalance valves, industries can achieve improved performance, sustainability, and a safer working environment.

Proper maintenance of Rexroth Counterbalance Valves is paramount for ensuring long-term performance and reliability. Regular checks and servicing can prevent potential issues that might arise due to wear and tear, dirt accumulation, and component fatigue. Typical maintenance practices include:

In the event of a suspected malfunction, troubleshooting should begin with a systematic approach to identifying the issue. Common signs of potential problems include erratic load movements, excessive noise, or valve leakage. It’s essential to isolate the valve system and assess the hydraulic circuit for:

For any complex issues that cannot be resolved through basic troubleshooting, consulting the manufacturer’s guidelines or seeking assistance from experienced hydraulic professionals is advised. Correctly addressing and resolving issues ensures that the counterbalance valves perform reliably and safely throughout their expected lifespan.

As technology in hydraulic engineering progresses, the development of Rexroth Counterbalance Valves is likely to embrace advancements in smart technology and automation. Future iterations may incorporate features such as IoT capabilities, allowing for remote monitoring and real-time diagnostics of valve performance. This evolution could lead to enhanced predictive maintenance strategies, where data analytics provide insights on potential issues before they lead to failure.

Moreover, innovations in materials and design might improve the durability and responsiveness of counterbalance valves, resulting in lighter and more efficient products. These advancements could be essential in industries facing increasing demands for efficiency, such as electric vehicles, where weight and performance optimization are critical.

Furthermore, with a growing focus on sustainability, manufacturers might look to develop environmentally friendly hydraulic fluid options, paired with valves that can operate effectively under lower pressures and energy consumption levels. Such sustainable solutions will align with broader industry goals toward reducing the environmental impact of hydraulic operations.

In summary, the future of Rexroth Counterbalance Valves appears to be focused on not only improving technical performance but also integrating the latest technological advancements to facilitate smarter, safer, and more efficient machinery operations. As industries evolve, the role of these valves will remain crucial in meeting the challenges posed by modern hydraulic systems.

In conclusion, the Rexroth Counterbalance Valve is a cornerstone of hydraulic system safety and efficiency, serving diverse industries that rely on precise pressure control and load management. Understanding its operation, applications, and advantages will significantly benefit professionals involved in the maintenance and deployment of hydraulic systems. The decision to implement these valves can often determine not just operational success but also impact the overall safety standards observed in various industrial environments. By embracing technology such as Rexroth's counterbalance valves, industries can achieve improved performance, sustainability, and a safer working environment.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!