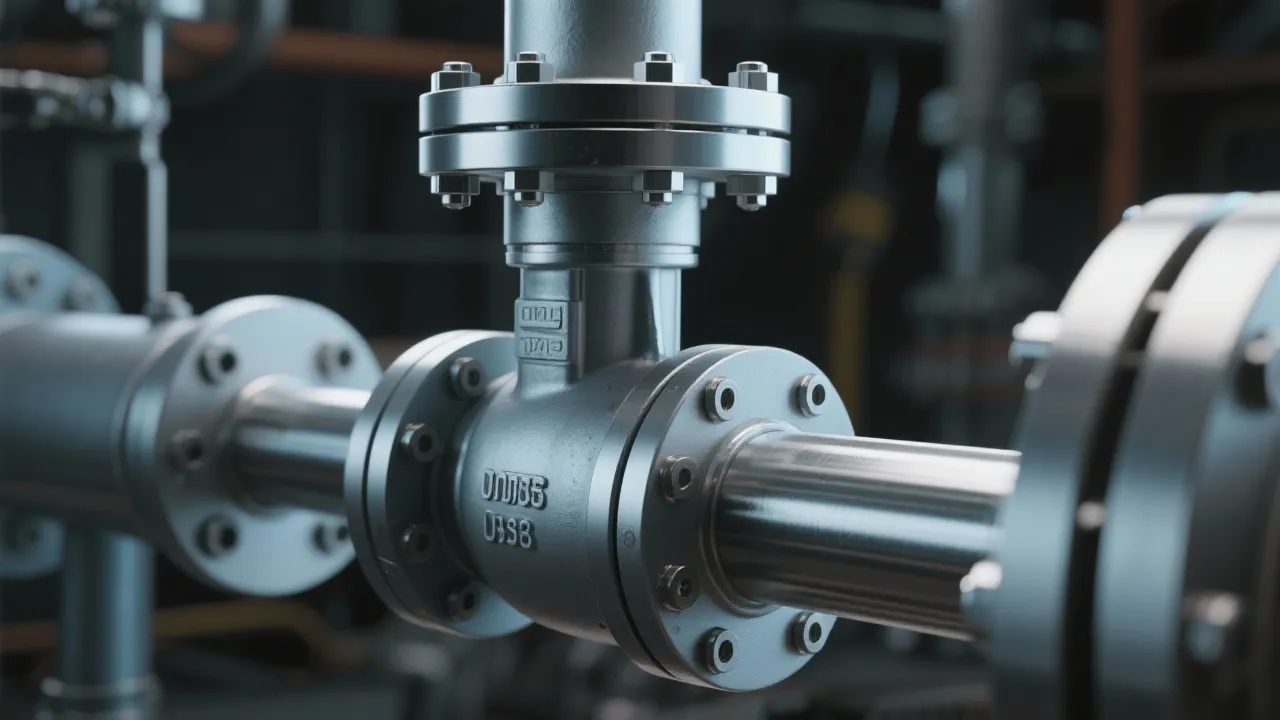

This article delves into the intricacies of Parker Proportional Valves, essential components in fluid control systems renowned for their precision and reliability. Proportional valves by Parker are predominantly used in industries requiring accurate flow and pressure regulation. These components have revolutionized how manufacturers and engineers approach system design and maintenance.

In the realm of industrial automation and fluid power systems, Parker Proportional Valves are pivotal for achieving unparalleled accuracy and efficiency in controlling fluid flow. These valves operate by varying the flow or pressure proportionally to an electrical input signal, allowing for precise control over different operational parameters. This unique capability enables industries to achieve optimized processes, reduce wastage, and manipulate system outputs with remarkable sensitivity.

At the core of a Parker Proportional Valve is the ability to meticulously control pressure and flow rates with precision that traditional on/off type valves cannot match. Proportional valves respond to varying electrical input signals, which adjust the position of the valve piston, finely tuning the rate of fluid flow or pressure delivered downstream. This capability makes them indispensable in sectors that require nuanced control, such as in hydraulic systems, process industries, and sophisticated manufacturing environments.

Unlike conventional control methods, Parker Proportional Valves utilize an electromagnetic solenoid that adjusts the flap or spool within the valve according to the input current. As the electrical signal changes, the valve’s position and the resulting flow rate or pressure adjust in real time. This continuous modulation allows for smooth transitions in operation, drastically reducing the mechanical stress on connected components while providing improved responsiveness and reliability.

Furthermore, the design of Parker Proportional Valves involves various components such as the actuator, feedback sensor, and control electronics which work cohesively to ensure the valve performs optimally. From a mechanical perspective, several types exist, including direct-acting, pilot-operated, and servo-controlled valves, each suited for specific applications based on their operating principles. Understanding these mechanisms is crucial for selecting the appropriate valve type for a given task.

What sets Parker Proportional Valves apart is their robust construction, dependability, and the flexibility they offer in complex systems. Parker's range of proportional valves is renowned for delivering consistent performance under varying environmental conditions, making them ideal for challenging industrial applications. Parker pays immense attention to the materials used in valve production, ensuring they can withstand harsh operating environments, including fluctuations in temperature, exposure to corrosive substances, and high-pressure conditions.

Moreover, these valves often feature advanced design elements aimed at minimizing leaks and maximizing efficiency, which is critical in applications such as chemical processing and hydraulic machinery. The durability of Parker Proportional Valves ensures reduced maintenance costs and a longer lifecycle, thus benefiting businesses by lowering operational expenses over time.

Parker also emphasizes ongoing innovation, continually updating its technology to enhance performance and adapt to emerging industry challenges. Their research and development initiatives focus on integrating intelligent control systems that enable predictive maintenance, further refining the capabilities of their proportional valves. Such forward-thinking not only enhances the functionality of valves but also positions Parker as a leader in fluid control technologies.

The utilization of Parker Proportional Valves spans multiple sectors such as automotive manufacturing, aerospace, and mobile machinery. These valves empower engineers to streamline processes, enhance efficiency, and reduce environmental impact through precision control of hydraulic and pneumatic systems. Their role in optimizing the operation of construction machinery, for instance, highlights the significance of these valves in impacting efficiency and safety on the job site.

In the automotive industry, Parker Proportional Valves are integral to the operation of various systems, including anti-lock brakes, steering systems, and engine control management, where they provide necessary adjustments in real time to improve vehicle safety and performance. In manufacturing, they facilitate the control of robotic arms, ensuring delicate components are handled with precision, which is crucial in high-stakes environments such as electronics assembly or medical device production. This level of precision not only enhances product quality but also reduces error rates significantly.

Moreover, in the aerospace industry, Parker's valves are employed in critical systems, including fuel control and cabin pressurization systems. Altitude and pressure dynamics requiring immaculate timing and responsiveness can be achieved through Parker's advanced proportional valves, which ensures the safety and reliability of aircraft operations.

| Industry | Application |

|---|---|

| Automotive | Used in paint spraying systems for precise control. |

| Manufacturing | Regulating the pressure and flow in robotic arms. |

| Aerospace | Used in fuel control systems to manage flow dynamics. |

| Construction | Optimizing hydraulic controls in heavy machinery for improved efficiency and safety. |

| Chemical Processing | Employing precise pressure control to improve safety and operational effectiveness. |

The adaptability of Parker Proportional Valves allows them to be customized and integrated into various systems, thereby enhancing the overall productivity of the machines they operate within. It is this versatility combined with proven performance metrics that makes Parker Proportional Valves a preferred choice across multiple sectors.

When choosing a Parker Proportional Valve, it's essential to consider specific parameters such as flow rate capacity, pressure range, and electrical compatibility. Parker offers a wide array of models designed to meet the intricate requirements of various systems, each engineered to meet precise specifications for optimal performance. Understanding these technical specifications is crucial for ensuring that the valve can perform under the intended application conditions.

Flow rate is generally measured in liters per minute (LPM) or gallons per minute (GPM) and dictates how much fluid can pass through the valve in a given timeframe. The pressure range denotes the maximum and minimum pressures that the valve can withstand, which is vital for applications where pressure can vary significantly. Electrical compatibility often involves the voltage ratings and current requirements for the solenoid coil, making it imperative to match these parameters with the existing control systems. Additionally, options for communication interfaces (like CAN bus or analog signals) and feedback mechanisms are available to cater to modern automation needs.

Valves are typically available in various sizes and body configurations, allowing them to fit seamlessly into diverse systems while maintaining performance standards. Hydraulic and pneumatic variants are offered, allowing for specific selections based on the fluid dynamics of the respective application. Furthermore, Parker provides comprehensive documentation that includes performance curves, installation guidelines, and maintenance recommendations, ensuring end users have all the information needed to operate them efficiently.

One of the hallmark features of Parker Proportional Valves is their ability to provide soft start controls, essential for preventing shock loading in hydraulic circuits. This feature not only enhances the longevity of the system but also leads to quieter operation, a factor increasingly important in environments where noise pollution is a concern.

As industries continue to push towards more precise, efficient, and environmentally conscious operations, Parker Proportional Valves exemplify innovation in fluid control technology. Their robust performance in demanding environments ensures they remain at the forefront of industry advancements, providing crucial support in optimizing numerous industrial processes. With the capacity to streamline operations, enhance reliability, and support evolving technological demands, Parker Proportional Valves stand as a benchmark for quality and innovation in fluid control solutions.

As technological advances continue to progress, the integration of smart technology in Parker Proportional Valves will remain an area of focus. Innovations such as IoT-enabled devices are becoming increasingly vital, allowing for predictive maintenance and remote monitoring of systems. Such developments are not merely enhancing the functionality of the valves but significantly improve the operational landscape of whole industries.

In summary, choosing Parker Proportional Valves means aligning with a trusted provider that not only understands the mechanical intricacies of fluid control but is also committed to leading the industry in quality, efficiency, and innovation. For businesses seeking optimal solutions for their fluid power systems, investing in Parker's advanced technologies ensures they remain competitive while driving towards greater sustainability and efficiency in their operations.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!