This article delves into the functionality and importance of Rexroth Counterbalance Valves in hydraulic systems. Known for their precision in controlling fluid flow and enhancing system stability, these valves are integral to machinery across industries. By balancing pressure and preventing cavitation, they help maintain system efficiency and safety.

In the realm of hydraulic systems, precision, efficiency, and reliability are paramount. The Rexroth Counterbalance Valve exemplifies these attributes, playing a crucial role in controlling fluid dynamics within various mechanical applications. These valves are not merely components; they are pivotal in ensuring the safety and efficacy of complex hydraulic systems, making them indispensable in industries ranging from construction to aerospace. Their implementation can significantly elevate operational safety, especially in sectors where heavy loads are commonplace.

As systems grow more complex and the demand for efficiency increases, the role of counterbalance valves becomes ever more critical. The combination of advanced technology and skilled engineering ensures these components not only function optimally but also adapt to evolving mechanized demands. An understanding of their operations, applications, and benefits can be the difference between successful implementation and catastrophic failures, making comprehensive knowledge imperative for engineers and technicians alike.

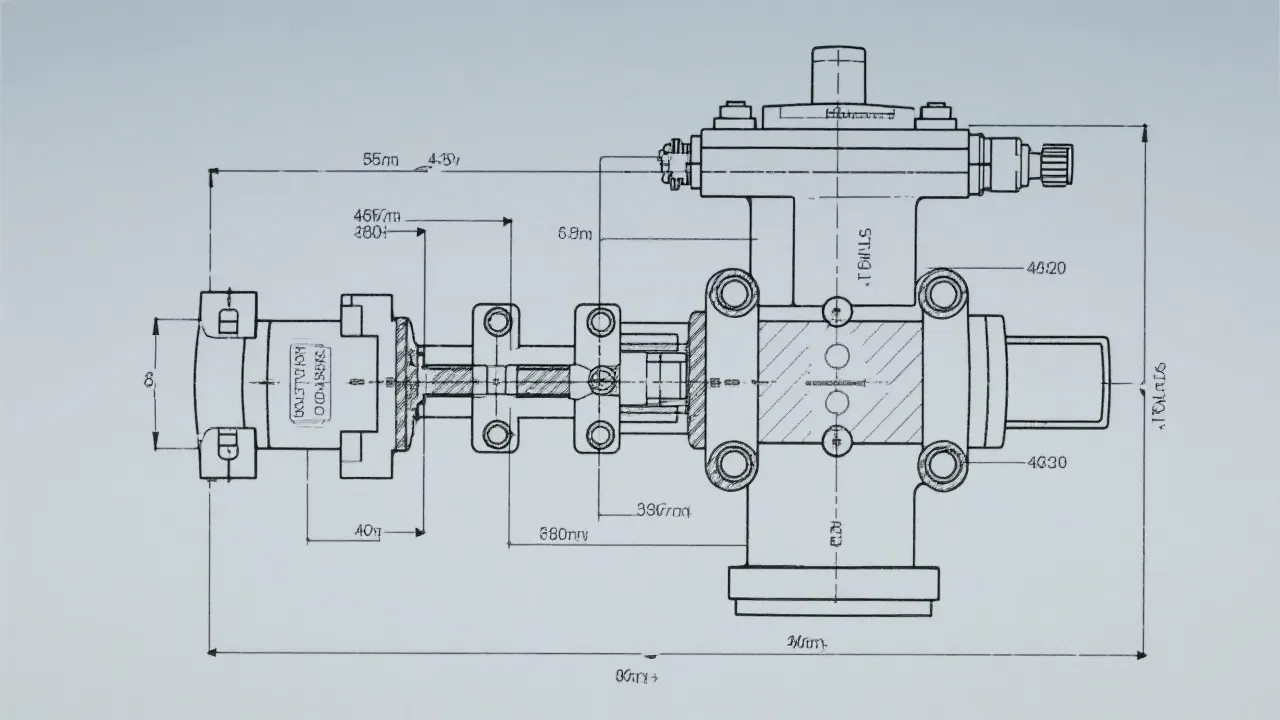

Rexroth Counterbalance Valves are engineered to manage pressure within hydraulic systems, thereby preventing undesired movements and potential system failures. They achieve this by maintaining back pressure, which safeguards against cavitation and facilitates controlled descent and ascent of loads. This precision control is vital for applications involving cranes, excavators, and other heavy machinery where stability and safety are of utmost importance.

Their functionality is rooted in a sophisticated mechanism that incorporates both mechanical and hydraulic principles. When a load is acted upon, the counterbalance valve allows fluid to flow while simultaneously applying resistance to prevent uncontrolled descent. This ensures that operators maintain precise control over the machinery, reducing the hazards associated with sudden drops or erratic movements. In industries such as construction, the safety of personnel and equipment can depend directly on these systems working effectively.

Experts in mechanical engineering emphasize the necessity of incorporating robust components like the Rexroth Counterbalance Valve in hydraulic systems to extend their lifespan and enhance reliability. The precision in manufacturing and the quality standards adhered to by Rexroth distinguish these valves from their counterparts, making them a preferred choice among industry leaders.

According to specialists, the integration of these valves not only improves hydraulic system performance but also plays a critical role in adhering to safety regulations. In a climate where operational safety guidelines continue to tighten, including well-designed counterbalance valves allows companies to bolster their compliance efforts. Evaluating the quality and features of counterbalance valves can lead to more informed decisions that benefit both operations and safety.

In construction, for instance, tower cranes rely heavily on counterbalance valves to ensure that loads can be lifted and transported safely. Without reliable hydraulic control, the risk of accidents skyrockets, leading to costly damage and potential injuries. A well-placed counterbalance valve ensures that even when a load is lifted at great heights, it will descend at a controlled speed and with minimal risk of dropping unexpectedly.

In the aerospace industry, hydraulic systems are utilized for landing gears and control surfaces, reinforcing the need for precise pressure regulation. The use of Rexroth Counterbalance Valves in these applications helps to ensure that critical mechanisms function correctly, even under extreme conditions. Experience from aerospace engineers demonstrates that installing high-quality valves can reduce maintenance needs and increase system operational time.

| Feature | Benefit |

|---|---|

| High Pressure Tolerance | Enables operation under extreme conditions, ensuring system durability and integrity during challenging tasks. |

| Precision Manufacturing | Offers superior accuracy in pressure control for safety and efficiency, minimizing operational risks associated with imprecision. |

| Versatile Configurations | Available in multiple configurations, tailored to various applications for optimized performance. |

| Durable Materials | Manufactured from high-quality materials designed to withstand wear and prolong the lifespan of the valve. |

To ensure the longevity and proper functioning of Rexroth Counterbalance Valves, regular maintenance is paramount. Focused on both inspection and preventive measures, these practices can prevent unexpected failures that could halt productivity and pose safety risks.

A routine inspection schedule is essential for identifying early signs of wear or damage. Technicians should frequently check for leaks, unusual noises, or pressure fluctuations. These indicators can signal potential problems that need addressing before they escalate. Inspections should also include checking seals and fittings, ensuring that connections remain tight and secure to prevent fluid loss.

The quality of hydraulic fluid is another vital component in the overall health of hydraulic systems. Contaminated or degraded fluid can prematurely age system components and lead to operational failures. Regular fluid analysis should be performed, looking for signs of contamination or degradation to guarantee that only clean, optimal fluid circulates through the hydraulic system.

Implementing periodic functional testing is essential in evaluating whether the counterbalance valve operates as expected under load conditions. Functional tests should simulate operational scenarios to confirm that the valve maintains back pressure during both lifting and lowering activities.

Industry experts advocate for following the manufacturer’s guidelines and recommendations, including particular bracing and installation specifications. Proper installation can significantly affect performance, making it critical to adhere to recommended practices. Increasing training efforts for personnel on these best practices is also beneficial in fostering a culture of safety and efficiency.

In addition to their basic functionalities, modern Rexroth Counterbalance Valves may include an array of advanced features that enhance their usage across various sectors.

Some models come equipped with integrated pressure relief features, allowing for better control and mitigating the risks associated with over-pressurization. This is particularly useful in high-stakes applications, where sudden pressure spikes could lead to catastrophic failures.

With the advent of smart technologies in hydraulic systems, electronic controls integrated with counterbalance valves provide automated feedback for managing pressure dynamically. This added layer of control allows for improved synchronization in multi-cylinder operations, thereby enhancing the precision of load management across numerous applications.

Energy-efficient designs are becoming increasingly crucial as industries strive to reduce their carbon footprint. Rexroth is committed to creating solutions that consume less energy while maintaining robust functionality. These innovations not only improve environmental sustainability but also reduce operating costs, an aspect that is highly valued in today's competitive market landscape.

These valves are primarily used in systems where load control and safety are critical, such as cranes, lifts, and hydraulic presses. In industries like construction and manufacturing, they provide essential safety features that prevent uncontrolled movements of heavy equipment.

By maintaining consistent pressure and preventing cavitation, Rexroth Counterbalance Valves safeguard hydraulic components, reducing wear and extending system lifespan. The consistent performance offered by these valves not only aids in durability but also ensures operational consistency, vital for meeting production demands.

Yes, these valves can be tailored to meet specific system requirements, ensuring optimal performance in diverse applications. Customization options mean that engineers can select specific parameters and configurations that align with operational goals and safety standards.

Regular maintenance typically includes inspection, fluid quality checks, and functional testing. Following manufacturer guidelines helps identify potential issues early and assures the longevity of the hydraulic system they serve.

As industries continue to rely on advanced hydraulic systems, the demand for reliable components like Rexroth Counterbalance Valves will only grow. Their capacity to enhance system stability, prevent mechanical wear, and maintain precise control underlines their indispensable role in modern engineering solutions. Integrating these valves into hydraulic systems not only ensures operational efficiency but also aligns with top practices in system safety and performance enhancement.

The future landscape of engineering will increasingly involve automated systems and smart technologies, and as such, the role of counterbalance valves will adapt and evolve alongside these advancements. Ongoing research, development, and innovation in hydraulic systems signify that Rexroth will continue to lead in providing exceptional valve solutions that address both today’s challenges and the future demands of the industry.

The integration of these sophisticated components reflects a larger trend of fostering safety and efficiency in engineering practices, a responsibility that lies at the heart of every professional's work. Therefore, understanding and utilizing products like the Rexroth Counterbalance Valve is crucial for engineers aiming to deliver optimal results while ensuring the utmost safety in their operations.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!