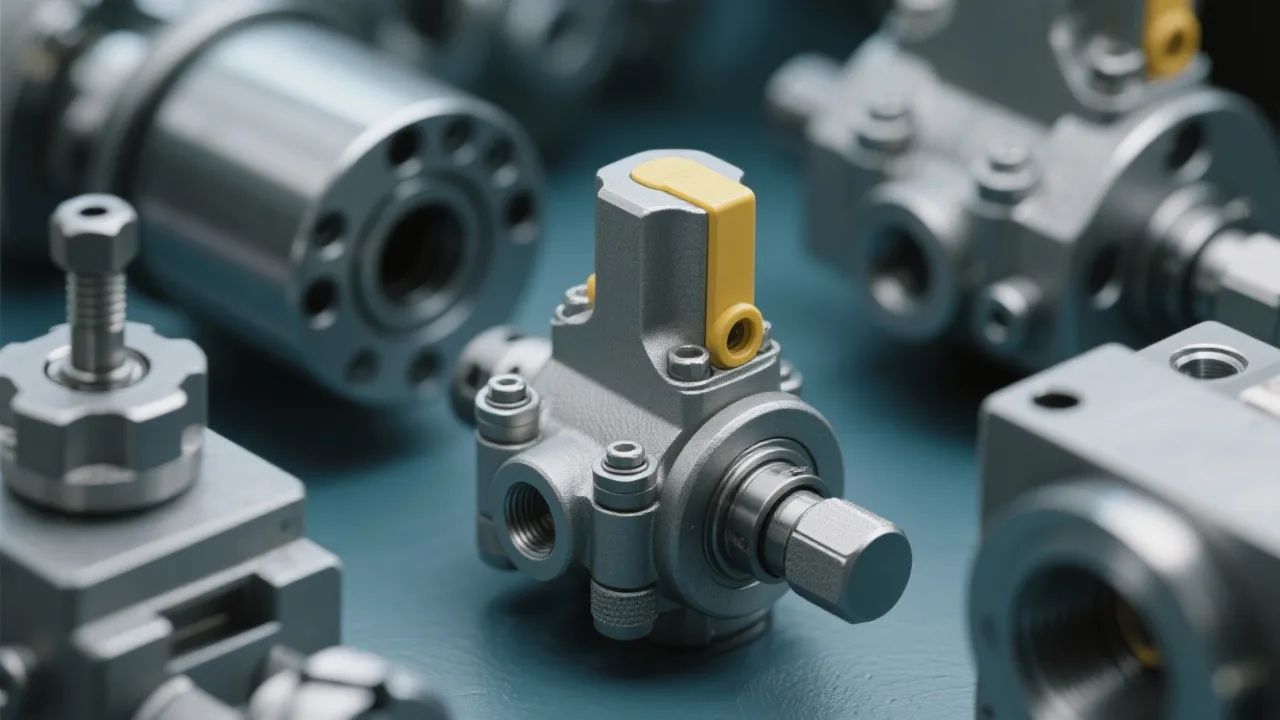

This article delves into the intricacies of the Rexroth Counterbalance Valve, highlighting its significance in hydraulic systems for controlling pressure and movement. Utilizing a balance of technical insight and practical perspective, it explores how this component enhances the efficiency and safety of machinery operations, making it an essential topic of study for industry professionals.

Rexroth counterbalance valves are vital components in hydraulic systems designed to maintain stable and controlled pressure under variable loads. They are predominantly used in heavy machinery and mobile equipment to prevent uncontrolled movements of hydraulic actuators, ensuring safety and precision in operations. These valves act as a safety net, holding loads securely in place while allowing for controlled movement when required. This importance cannot be overstated in industries where heavy loads are everyday occurrences. For instance, in construction and manufacturing, the ability to control load movements can prevent accidents that lead to injuries, material damage, and equipment malfunction.

The primary purpose of these valves is to hold a load securely, even when hydraulic power is lost, by employing hydraulic locking. This functionality is crucial in applications requiring secure positioning of loads—such as in cranes, aerial platforms, and forklifts. These valves essentially provide motion control by balancing the fluid flow to a hydraulic cylinder, thereby preventing movement when the system is at rest. Counterbalance valves also facilitate controlled movements even under dynamically changing loads, providing a stable platform for operations. When hydraulic pressure drops, either due to a power outage or a system failure, the counterbalance valve locks the hydraulic fluid in place, preventing the load from descending unexpectedly.

Rexroth's counterbalance valves are characterized by their precision-engineered design, offering features like pressure adjustment capacity to accommodate varying operational requirements. Typically, these valves boast a rugged construction to endure harsh operating environments, with materials resistant to wear and corrosion, which ensures longevity and reliable performance. Features such as adjustable pressure settings allow operators to fine-tune the valve according to the specific application, optimizing the entire hydraulic system's performance. Moreover, advanced designs incorporate technologies such as integrated check valves that enhance safety and functionality by allowing free flow in one direction while holding the load in the opposite direction. This dual functionality is particularly valuable in dynamic applications where load conditions can change rapidly.

Utilizing Rexroth counterbalance valves offers several benefits. These include enhanced operational safety by preventing the affordable-fall of loads, improved system efficiency by optimizing pressure and flow control, and the capability to function in a variety of hydraulic applications. Their versatility makes them indispensable in fields such as manufacturing, construction, and material handling. For example, in the construction industry, the risks associated with lifting and holding heavy materials are significantly mitigated by these valves. They ensure that cranes can hold loads securely at heights while workers operate below, thereby enhancing safety on construction sites. Similarly, in manufacturing, where precision and reliability are critical, implementing counterbalance valves contributes to a smoother workflow and minimizes the risk of equipment failure.

This section provides a comparative analysis of Rexroth counterbalance valves with those of other significant competitors in the market:

| Feature | Rexroth | Competitor A | Competitor B |

|---|---|---|---|

| Durability | High | Moderate | High |

| Pressure Range | Wide | Narrow | Wide |

| Cost | Premium | Budget | Premium |

| Availability | Global | Local | Global |

The analysis shows that while Rexroth products typically come with a premium price tag, they offer unmatched durability and a broad pressure range, which can justify the investment for many businesses. In contrast, competitors offering budget options may compromise on durability and adaptability, which can lead to long-term costs due to failure and maintenance needs. Customers must consider the total cost of ownership versus initial outlay when making their purchasing decisions.

Proper installation and regular maintenance are key to ensuring the optimal performance of Rexroth counterbalance valves:

Additionally, operators should be trained to recognize early warning signs of valve failure, such as irregular load behavior, unexpected pressure changes, and fluid leaks. Timely intervention can save significant repair costs and downtime.

Despite being designed for reliability, counterbalance valves can encounter issues that may require troubleshooting. Common problems include:

Rexroth counterbalance valves represent the pinnacle of engineering in hydraulic motion control. Their robust construction and adaptability across various industries make them an essential asset for ensuring safety and precision in hydraulic operations. Understanding their functionality and applications can significantly empower industry professionals to make informed decisions and improve system efficiencies. As businesses continue to prioritize safety and efficiency in operations, the role of counterbalance valves becomes even more crucial. Investing in high-quality components like Rexroth counterbalance valves can lead to enhanced performance, reduced downtime, and an overall increase in operational effectiveness. Additionally, staying updated on the latest innovations in hydraulic technology and interpretation of data provided by these valves can further enhance productivity and safety industries rely on.

The hydraulic industry is advancing rapidly, with ongoing research and development aimed at improving the performance of counterbalance valves. Future developments may focus on:

Staying abreast of these developments will be crucial for engineers, operators, and business leaders in ensuring their hydraulic systems remain efficient, safe, and competitive in an ever-evolving market.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!