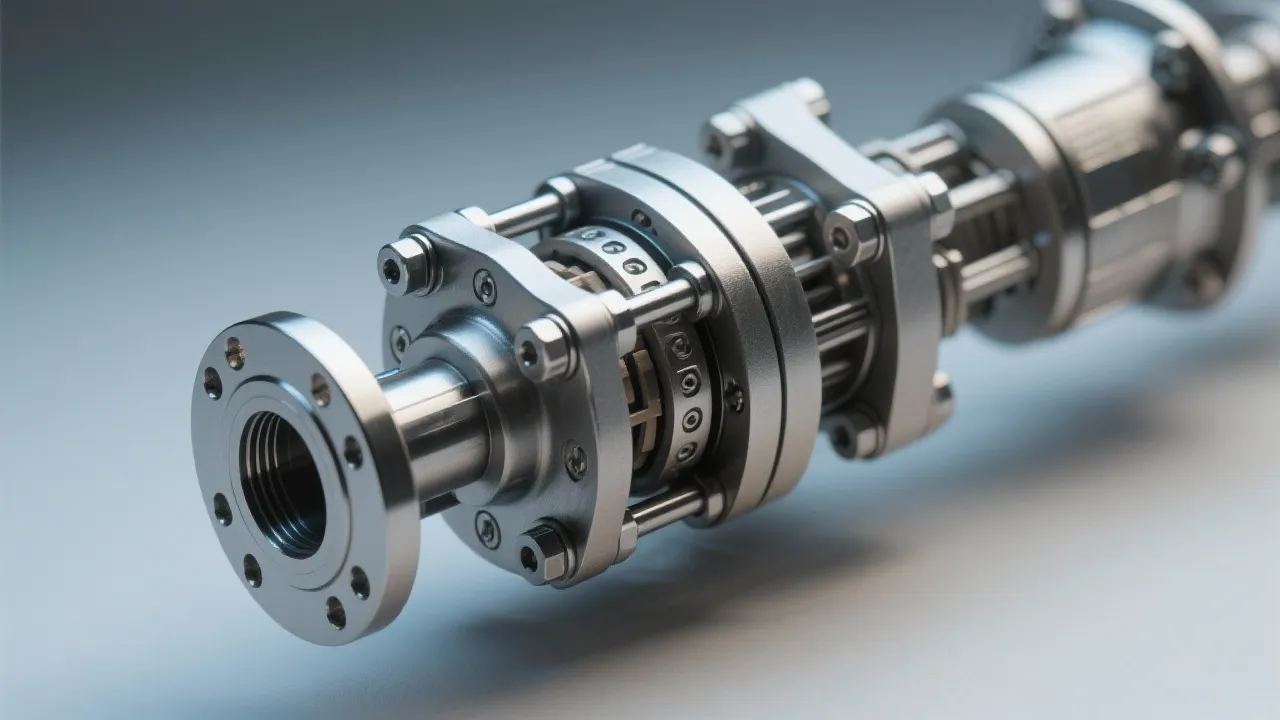

Parker Proportional Valves represent advanced solutions in fluid control technology, designed for precision and efficiency in various industrial applications. These valves boast superior performance through innovative engineering, ensuring adaptability to the requirements of modern machinery across diverse sectors, including manufacturing and automation.

Parker Proportional Valves are a cornerstone in fluid control systems, offering precise and adaptable solutions for today's industrial challenges. Engineered by Parker Hannifin, a leader in motion and control technologies, these valves are integral in applications requiring meticulous control of flow, direction, and pressure. Used extensively across manufacturing, automation, and various industrial processes, they meet the demands for high performance and reliability. The design ingenuity of Parker Proportional Valves brings together advanced engineering techniques and cutting-edge technologies, which have positioned these products at the forefront of the motion control market. They are utilized in various sectors, including aerospace, automotive, marine, and renewable energy, underscoring their versatility and importance in modern engineering.

The Parker Proportional Valve is designed with features that enhance its functionality and versatility. These valves provide electronic control of hydraulic and pneumatic systems, allowing for a seamless transition between different operation states. This is crucial for industries that depend on the fine-tuning of fluid power systems, as it leads to improved product quality and operational efficiency. For instance, in the automotive manufacturing sector, proportional valves enhance the precision of robotic assembly lines by allowing for gradual and variable adjustments in hydraulic pressure, which translate to smoother operations and reduced wear on machinery.

Not only do these valves support efficiency, but they also contribute to energy savings. By optimizing the amount of power required for system operations, Parker Proportional Valves offer a sustainable option for energy-conscious industries. Their ability to adjust flow rates dynamically based on demand minimizes energy waste, thereby reducing overall operational costs. This feature is especially vital in industries like plastics processing, where energy consumption can significantly impact profitability, particularly with the rising costs of electricity and a growing focus on sustainability.

Experts in the field of fluid dynamics praise the engineering precision and modular capabilities of Parker Proportional Valves. "Their adaptability and precision are unparalleled," notes John Benson, a veteran mechanical engineer. According to Benson, these valves facilitate streamlined operations, reduce downtime, and enhance overall system reliability. He highlights that the modular design of Parker Proportional Valves allows for easy replacement and upgrades, meaning businesses can adapt to changing needs without overhauling entire systems. Furthermore, this modularity is key in industries like aerospace, where compliance with strict regulations often demands the use of components that can perform reliably over time while allowing for future enhancements without significant downtime.

Understanding the technical specifications of Parker Proportional Valves is crucial for selecting the right model for your application. These valves are available in various sizes and configurations, each suited for particular pressure ratings and flow capacities. Integrating these valves into your system requires consultation with industry professionals to ensure compatibility and optimal performance. It’s essential to analyze the specific requirements of your operational framework—such as maximum flow rates, operating pressures, and response times—to determine the best model. Furthermore, the installation typically requires specialized knowledge to ensure correct setup and function, emphasizing the need for professional input during the integration process.

| Model | Flow Capacity | Pressure Rating |

|---|---|---|

| Parker D1FC/D3FC | Up to 350 L/min | Up to 350 bar |

| Parker D1FB/D3FB | Max 500 L/min | 400 bar |

| Parker D1LV | 300 L/min | 250 bar |

| Parker D1FP | 600 L/min | 500 bar |

| Parker D1PD | 100 L/min | 200 bar |

| Parker D1EC | 300 L/min | 350 bar |

Parker Hannifin's proportional valves are widely distributed through authorized suppliers, ensuring that clients worldwide have access to high-quality components. These suppliers offer technical support and necessary after-sales services to maintain operational continuity. The global supply network established by Parker Hannifin ensures that components are readily available, reducing lead times for critical applications. Suppliers provide not only the products but also essential guidance on installation and integration, ensuring that businesses can quickly adapt to new technologies without significant long-term disruption.

Moreover, suppliers often have localized support teams who can offer troubleshooting and maintenance services, a crucial factor for companies relying on just-in-time processes. Many distributors provide online resources such as user manuals, application guides, and additional technical data, empowering customers to make informed purchasing decisions tailored to their operational needs.

Parker Proportional Valves have found extensive applications in diverse industries, showcasing their versatility. Below, we explore several notable use cases to highlight the breadth of their applications:

In the aerospace sector, Parker Proportional Valves are employed in flight control systems where precision and reliability are paramount. They control hydraulic actuators that move various flight surfaces, enabling smooth and accurate control of aircraft. The capability to provide fine control at various speeds ensures optimal performance during different phases of flight, from takeoff to landing. Furthermore, the stringent regulatory standards in aerospace necessitate that these valves operate flawlessly under high-stress conditions, reflecting a growing industry reliance on advanced technology for safety and performance.

In automotive production lines, Parker Proportional Valves play a crucial role in robotic arms and assembly systems. The ability to control hydraulic fluid flow and pressure with extreme accuracy leads to enhanced assembly precision, leading to higher quality outputs and reduced rework costs. Furthermore, these valves can be adjusted dynamically in real-time based on feedback from sensors, allowing for adaptive control that minimizes errors during assembly processes.

In the plastics industry, the valves are integral to processes such as injection molding, where precise control of hydraulic pressure can mean the difference between a well-formed plastic part and a defective one. Proportional valves facilitate the complex interactions required during molding, ensuring that the plastic is injected at the exact temperature and pressure needed to achieve the desired outcomes. Additionally, in packaging operations, proportional valves control the movement of actuators involved in packing machinery, ensuring reliable operation and minimizing downtime.

The renewable energy sector, particularly wind energy, has also embraced Parker Proportional Valves for their reliability and efficiency. These valves are used in pitch control systems that adjust the angle of turbine blades to optimize energy collection based on wind conditions. In solar panel installations, proportional valves help manage the hydraulic systems that adjust panel angles, maximizing exposure to sunlight. By increasing energy capture efficiency, they contribute to the overall growth and sustainability of the energy sector, aligning with global efforts toward greener solutions.

Proper maintenance of Parker Proportional Valves is essential to ensure their longevity and performance. Regular maintenance schedules should be established based on operational demands and environmental conditions. Key maintenance tasks include checking fluid levels, inspecting seals for wear, and ensuring the cleanliness of hydraulic systems to prevent contamination.

Additionally, troubleshooting any issues with proportional valves can often involve checking electrical connections, inspecting sensors for proper operation, and monitoring system pressures. Anticipating potential issues can save significant costs associated with unexpected downtimes. Many suppliers offer training sessions aimed at user familiarity with both the technology and standard maintenance procedures, providing clients with the knowledge to enhance their operational reliability.

The landscape of proportional valve technology is evolving, driven by advancements in digital electronics and automation. Future trends suggest an increasing emphasis on the integration of smart technologies into these valves. This includes the implementation of IoT (Internet of Things) capabilities, allowing for remote monitoring and diagnostics, predictive maintenance, and data-driven decision-making in fluid control systems.

Moreover, the evolution of artificial intelligence (AI) is poised to influence how these valves operate, with algorithms capable of optimizing valve performance based on real-time data. Enhanced connectivity through smart sensors will enable proportional valves to adjust their operations automatically, creating more intelligent and efficient systems capable of adapting to dynamic operational demands.

As industries move towards automation, the importance of seamless integration between components will become even more crucial. The proportional valves of the future will need to interface smoothly with other automated systems, facilitating improved processes while also fulfilling the rising demand for sustainability in manufacturing practices. Energy efficiency will continue to be a primary focus, driving innovations aimed at reducing the energy footprint associated with fluid control.

In conclusion, Parker Proportional Valves are a testament to engineering excellence, ideal for industries looking to enhance their fluid control systems with reliable and efficient solutions. As technological advancements propel industrial processes forward, the role of such precision-engineered components becomes ever more critical. Their sophisticated functionality, combined with a commitment to energy efficiency and adaptability, makes them indispensable in current industrial applications and positions them for future advancements. Companies across diverse sectors can greatly benefit from investing in these innovative fluid control solutions, leading to enhanced operational performance, sustainability, and growth in a competitive marketplace.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!