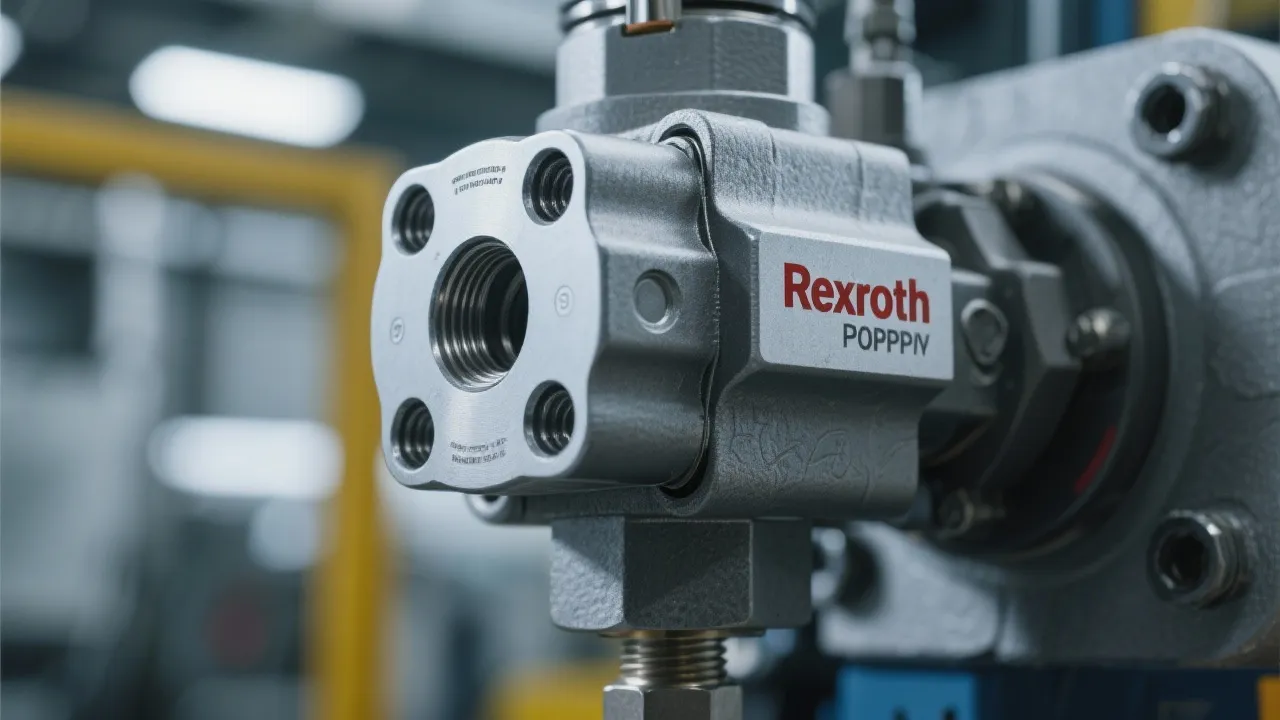

This article delves into the intricacies of Rexroth Poppet Valves, exploring their vital role in industrial applications. Rexroth, a leading name in hydraulic and automation solutions, has engineered poppet valves that are known for their reliability and efficiency. Known for their robust performance, these valves are critical components in various hydraulic systems. By examining their design and applications, this guide helps engineers and industry professionals better understand and utilize Rexroth Poppet Valves.

The Rexroth Poppet Valve is an essential component in modern hydraulic systems utilized in various industrial applications. It is renowned for its durability, precision, and efficiency in controlling the flow of fluids within these systems. Bosch Rexroth, a leading provider of drive and control technologies, designs these valves to meet stringent industry standards, ensuring optimal performance in demanding environments. The evolution of hydraulic technology over the years has seen these valves adapt to meet new challenges, influencing the efficiency and functionality of hydraulic systems in numerous industries.

Rexroth poppet valves are expertly designed to offer high flow capacity and low leakage. They operate by rapidly opening and closing a cylindrical poppet element, which provides a quick and direct path for fluid flow. This mechanism is crucial in applications requiring stringent control of pressure and flow rates, as it minimizes response time and maximizes operational efficiency. Hysteresis, or the lag in response time observed in other types of valves, is significantly reduced in poppet valves, making them a preferred choice in dynamic applications.

As an industry expert, Rexroth's engineering leverages advanced materials and cutting-edge technology, ensuring these valves can withstand extensive use and harsh operational conditions. Through careful selection of materials, such as high-strength alloys and resistant coatings, Rexroth enhances the performance characteristics of poppet valves, enabling them to function seamlessly in extreme environments ranging from high temperatures to corrosive agents.

This design philosophy is further complemented by rigorous testing and quality assurance processes, ensuring that each valve not only meets but exceeds industry performance standards. The integration of smart technology into some of the newer designs facilitates real-time monitoring and diagnostics of valve performance, opening up avenues for predictive maintenance and enhanced operational oversight.

These valves are integral in industries such as manufacturing, automotive, and energy. In particular, the agricultural and construction sectors benefit from their reliability in hydraulic machinery, enhancing the equipment's ability to perform under high pressure and extended cycles. In manufacturing, they play a crucial role in assembly lines, facilitating quick movements and precise control over various processes.

Furthermore, the versatility of Rexroth poppet valves extends to mobile equipment and machinery, where their compact size and robust build allow for integration in confined spaces without compromising performance. Applications range widely, from controlling hydraulic motors in heavy machinery to managing fluid flows in industrial automation systems.

In the automotive industry, Rexroth poppet valves are utilized in hydraulic brake systems and power steering systems, critical for vehicle safety and performance. The ability to maintain consistent pressure and reliability in these systems directly impacts driving dynamics and the overall safety of the vehicle.

Moreover, in the renewable energy sector, especially in wind turbine manufacturing and hydraulic fracturing in oil and gas, these valves prove indispensable. The ability to control fluid flow accurately under varying environmental conditions ensures optimal energy harnessing and resource extraction processes.

The significance of these valves is further underscored by regulatory requirements in several industries, which mandate the use of reliable components to ensure not only operational efficiency but also safety and compliance with environmental standards.

| Feature | Rexroth | Competitors |

|---|---|---|

| Durability | High-grade materials, ensuring longevity and resistance to wear | Varies, often with lower grade materials which may lead to faster deterioration |

| Efficiency | Optimized for low leakage rates and high flow capacity | Generally efficient but may exhibit higher leakage rates impacting overall system performance |

| Operational Range | Wide operational temperature and pressure range, adaptable to various conditions | Limited ranges compared to Rexroth, restricting their application scope |

| Technological Integration | Incorporates smart technology for advanced performance monitoring | Less advanced integration in many competitor models |

| After-sales Support | Strong global support network with specialized technical assistance | Varies; some competitors may not offer dedicated support |

When procuring Rexroth Poppet Valves, it is essential to consider a reputable supplier who can provide not only genuine parts but also insightful support and after-sales service. Verify their expertise in hydraulic infrastructures to ensure continuity and reliability of supply. Additionally, exploring the supplier's background in technical knowledge and customer service can significantly impact the overall procurement experience.

Potential buyers should engage with suppliers who have a proven track record of delivering Rexroth products, as this can assure that the equipment meets industry standards and performance expectations. Attending industry exhibitions and trade shows can also provide direct access to Rexroth representatives and authorized dealers, allowing users to gain deeper insights into the latest technologies and offerings.

Another critical consideration when acquiring these valves is availability and lead times. Rexroth offers a range of models tailored for different applications, and understanding stock levels and delivery capabilities can influence project timelines and operational workflows. Ensuring direct communication with suppliers regarding these factors helps avoid unexpected delays and enhances project management.

For optimal operation, it is crucial that these valves are installed correctly, adhering to manufacturer guidelines. Detailed installation instructions are often provided by Rexroth, which should be followed carefully to prevent any operational anomalies. This includes correct orientation, torque settings for fittings, and ensuring cleanliness of the hydraulic circuit to avoid contamination.

Regular maintenance involving inspection for signs of wear and periodic testing of pressure settings is recommended to maintain the system's integrity and prolong the lifespan of the valves. Maintenance schedules should ideally be defined based on operational usage patterns and environmental conditions.

Proper lubrication and regular cleaning are essential parts of valve maintenance to prevent sticking and ensure smooth operation. In addition, keeping thorough records of maintenance activities can provide essential data for analyzing performance trends and spotting potential issues early on.

Training staff on the specifics of Rexroth poppet valve operation, maintenance, and troubleshooting can further enhance system reliability. Well-informed personnel can more readily identify out-of-spec conditions and respond appropriately, reducing downtime and maximizing the effectiveness of hydraulic systems.

Rexroth Poppet Valves represent a pinnacle of engineering excellence in hydraulic systems. Their widespread use across industries is a testament to the quality and reliability that Bosch Rexroth consistently delivers. Understanding their design and application can significantly enhance the efficiency and effectiveness of hydraulic solutions. With continuous advancements in technology, the future of Rexroth poppet valves looks promising, further solidifying their role as a cornerstone component in hydraulic systems.

As industries continue to evolve, especially with trends towards automation and increased operational demands, the importance of selecting the right components cannot be overstated. The choice of using Rexroth poppet valves thus emerges as not just a decision based on current needs, but a strategic investment aimed at future-proofing industrial processes and enhancing overall productivity.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!