Rexroth Modular Valves are essential components in modern hydraulic and pneumatic systems. These valves streamline operations in many industrial applications by offering flexibility, precision, and reliability. Widely used across various sectors, their design caters to specific fluid control needs, which significantly enhances performance, reduces downtime, and lowers maintenance costs.

In the realm of industrial applications, where precision and reliability are non-negotiable, Rexroth Modular Valves stand out as indispensable components of fluid control systems. Known for their flexibility, these valves support complex hydraulic and pneumatic operations by providing tailored solutions that meet specific industrial needs. Companies across diverse sectors rely on these valves to enhance performance, improve efficiency, and reduce costs associated with system downtime and maintenance. Their innovative design has redefined the industry standards, making Rexroth a trusted name among engineers and operators alike. This introduction aims to explore the in-depth attributes of Rexroth Modular Valves, covering their essential functions, advantages, and applications in various industries.

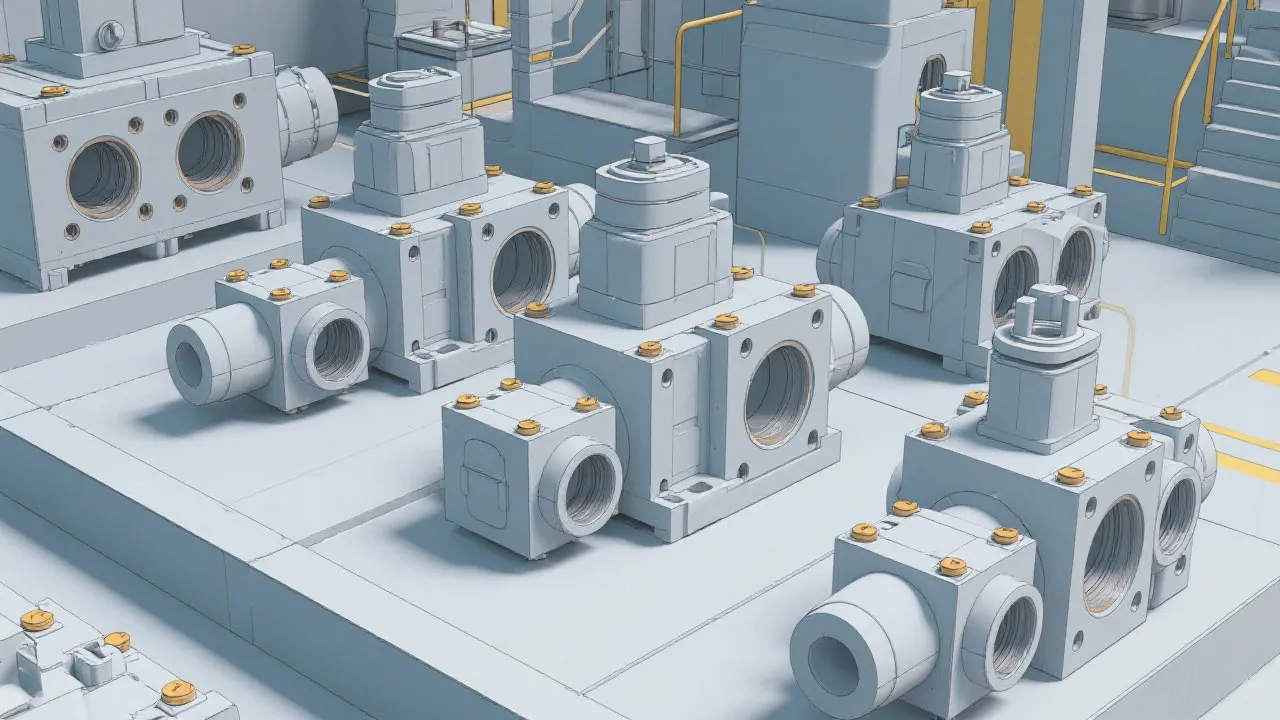

Modular valves, like those designed by Rexroth, are integral to controlling the flow and direction of hydraulic fluids within complex machinery. These valves are renowned for their stackable design, which facilitates customized configurations. Such adaptability is pivotal in scenarios demanding varied pressure levels, directional flow control, or integrated safety features, making them a cornerstone in industries such as automotive manufacturing, aerospace, and large-scale production facilities. Their versatility allows engineers to design systems that can be easily modified for specific functions, which is crucial in today’s fast-paced industrial environments where demand fluctuates rapidly.

Moreover, these modular valves can be integrated with electronic control systems, providing real-time data and automated control that allows for optimum performance. This integration is essential in minimizing human error and enhancing system predictability, thereby optimizing overall operational efficiency. The ability to incorporate sensors and actuators further highlights the role of Rexroth modular valves in smart manufacturing applications, where Industry 4.0 technologies come into play.

Rexroth Modular Valves are engineered to deliver high performance under challenging conditions. Here are the key advantages that highlight their industrial prominence:

The versatility of Rexroth Modular Valves allows them to be adapted across a wide range of applications. From high-precision manufacturing to heavy-duty construction machinery, these valves optimize fluid dynamics, ensuring that each sector benefits from improved efficiency and output. Their applications span various industries including:

From an engineering perspective, the technical prowess of Rexroth Modular Valves includes superior flow rates, maximum pressure endurance, and exceptional durability. Their ability to integrate seamlessly into advanced control systems speaks to their innovative design and superior material selection — crafted to withstand harsh industrial environments. Key specifications often considered by engineers include:

Q: What makes Rexroth Modular Valves suitable for industrial use?

A: Their robust construction and adaptable configurations make them ideal for a variety of industrial applications, enhancing system reliability and efficiency. The high-quality materials and engineering practices ensure that they can withstand rigorous operational demands.

Q: How do Rexroth Modular Valves improve system performance?

A: By offering precise flow and pressure control, these valves reduce energy consumption and wear in hydraulic systems, leading to lower operational costs and extended equipment lifespans.

Q: Are Rexroth Modular Valves easy to maintain?

A: Yes, their design allows for easy maintenance and reconfiguration, which reduces system downtime significantly. The modular design ensures that technicians can quickly replace or service individual components without the need for extensive system overhauls.

Rexroth Modular Valves have cemented their position as essential components in industrial fluid control solutions. Their ability to adapt to diverse applications while maintaining high levels of performance and efficiency sets a benchmark in the industry. As technology advances, the role of these modular valves will likely become even more prominent, further supporting industries in achieving operational excellence and sustainability. Engineers and operators can embrace this evolution by implementing modular designs that prioritize flexibility, responsiveness, and energy efficiency. The demand for smart, interconnected systems in today's industrial landscape emphasizes the need for reliable components, and Rexroth Modular Valves are perfectly positioned to meet these challenges.

As the future of the industry leans toward digitalization and automation, the advancements in modular valve technology are expected to play a significant role. Innovations in sensor technology and the Internet of Things (IoT) are paving the way for smarter and more efficient systems. Rexroth is at the forefront of these developments, positioning their modular valves not just as mechanical components but as crucial players in the network of smart factories.

One key trend in modular valve technology is the rise of predictive maintenance. Advanced sensors can monitor the performance of valves in real-time, allowing for the early detection of issues before they lead to failures. This proactive approach enhances reliability, reduces emergency maintenance costs, and maximizes the lifespan of the equipment. Businesses that embrace this technology will be able to maintain continuity in operations while reducing unexpected downtimes. Furthermore, this often results in higher safety standards, as machinery can be maintained under optimal conditions, ensuring compliance with industry regulations.

Additionally, integration with machine learning algorithms will enable systems to optimize fluid flow patterns dynamically. This means that modular valves would not only respond to preset parameters but could adapt in real-time based on data received from various sensors throughout the production line. Such intelligence can lead to greater energy efficiency, as the demand for hydraulic pressure can be varied according to real-time requirements, significantly lowering operational costs.

While the implementation of Rexroth Modular Valves is rife with advantages, industry professionals must also anticipate challenges that could arise during integration. One of the primary obstacles is ensuring compatibility with existing systems, especially in older machinery that wasn’t originally designed to accommodate modular components. Engineers often face the dilemma of retrofitting entire systems or reworking significant sections of hydraulic circuits to facilitate the installation of these advanced valves.

To address this, careful planning is essential. Performing a thorough audit of existing systems allows teams to identify potential areas of conflict and streamline the transition to modular valve technology. Collaborative efforts between engineers and manufacturers can lead to bespoke solutions that meet specific needs without overhauling entire systems.

Training is another crucial aspect that should not be overlooked. As new technologies are adopted, it is vital for staff members to receive the appropriate training for the operation and maintenance of these advanced valve systems. Workshops, training sessions, and accessible resources will empower teams with the knowledge they need to effectively work with these technologies, fostering a culture of safety and productivity.

Several case studies exemplify the successful implementation of Rexroth Modular Valves across diverse industries. One notable example is in the automotive sector, where a leading manufacturer faced challenges related to inconsistent fluid pressure and flow rates in their assembly line. They turned to Rexroth Modular Valves to optimize their hydraulic systems.

By integrating these valves into their production line, the manufacturer achieved a remarkable improvement of 15% in efficiency. The ability to customize the valve configurations allowed them to tailor solutions for different assembly processes without halting production flow. Immediate discernible impacts included reduced cycle times, lower energy consumption, and ultimately higher profit margins. This successful collaboration highlights the necessity for robust and flexible solutions in modern manufacturing environments.

In the aerospace industry, another case study showcases how Rexroth Modular Valves enhanced flight simulator technology. A major aerospace player demanded high precision and reliability from their hydraulic systems used in flight simulation. By employing Rexroth’s modular solution, they achieved unparalleled performance, allowing for more realistic simulations. The improved control over hydraulic dynamics translated into better training outcomes for pilots, demonstrating the direct benefits of integrating advanced valve technologies into high-stake applications.

The introduction and continued adoption of Rexroth Modular Valves signify a groundbreaking evolution in fluid dynamics and control within industrial applications. As industries continue to embrace automation, efficiency, and smart technologies, these valves will remain fundamental to achieving operational excellence. Companies looking to upgrade their systems must consider factors such as compatibility, the skillset of staff, and ongoing maintenance needs when implementing modular valve technology.

In summary, for organizations in current and emerging industries, Rexroth Modular Valves provide versatile, efficient, and future-ready solutions that not only improve productivity but also offer a pathway toward sustainability. As technological innovations evolve, these valves will be crucial in defining advanced manufacturing scenarios, enabling companies to rise above competition while meeting the demands of sophisticated production systems with ease.

| Feature | Description |

|---|---|

| Stackable Design | Allows for easy customization and integration into various systems. |

| Durable Construction | Built to withstand harsh industrial environments and intense pressure levels. |

| High Precision | Provides optimal control over fluid dynamics within systems. |

| Integration Capability | Compatible with existing control systems, facilitating transition. |

| Predictive Maintenance Support | Equipped with sensors for real-time monitoring and diagnostics. |

| Energy Efficiency | Helps in reducing operational costs by optimizing fluid flow. |

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!