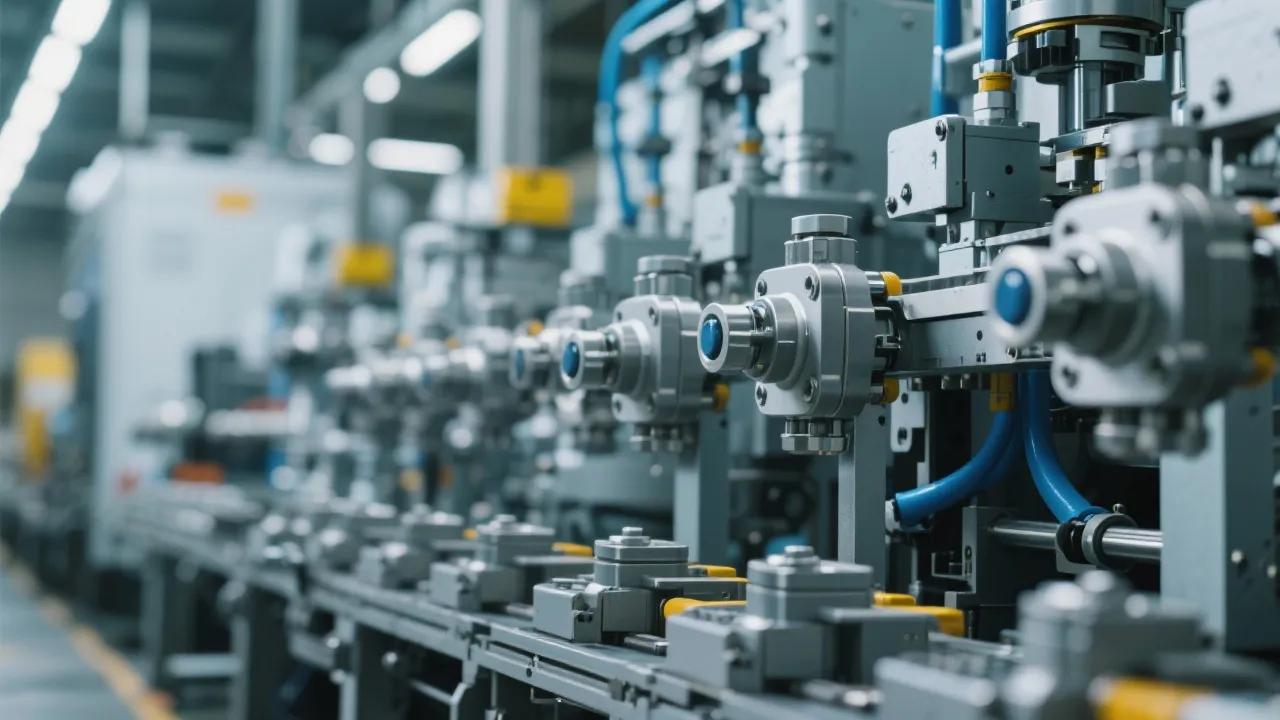

Rexroth Modular Valves play a crucial role in modern industrial applications, enabling efficient fluid control and automation. These valves, known for their modularity and precision, enhance system efficiency and flexibility. This article delves into the attributes, applications, and expert insights on these essential industrial components.

Rexroth Modular Valves are pivotal components in the field of hydraulic systems and automation. Renowned for their precision and adaptability, these valves offer innovative solutions for fluid control. As industries strive for greater efficiency and performance, Rexroth Modular Valves have emerged as vital elements, ensuring seamless operations across various sectors. The evolution of hydraulic systems has led to a growing demand for advanced components that can not only perform with efficacy but also adapt to the changing requirements of modern manufacturing and process control.

The distinct advantage of Rexroth Modular Valves lies in their modular design. Modularity facilitates the customization of fluid control systems, allowing engineers and technicians to tailor solutions for specific applications. This adaptability not only boosts operational efficiency but also simplifies maintenance, leading to reduced downtime and operational costs. By allowing for the easy addition or removal of components, modular systems reduce both the complexity and expense of system upgrades. Companies can respond more quickly to market changes, reconfiguring hydraulic circuits as needed without overhauling entire systems.

Furthermore, the modular design promotes standardization across various applications, helping industries streamline inventory and spare parts management. Engineers can easily mix and match different modules to create a comprehensive hydraulic system without sacrificing performance. This flexibility is crucial in industries that must adjust production lines swiftly to meet changing demands.

These valves find widespread applications in an array of industries, including manufacturing, automotive, and aerospace. Their capacity to manage complex hydraulic circuits makes them indispensable in heavy machinery, robotics, and automated production lines. Additionally, their robust design and reliable performance are crucial in environments that demand precision and consistency. In manufacturing, for instance, Rexroth Modular Valves play a vital role in facilitating the fluid movements required in assembly lines, helping to optimize processes and reduce cycle times.

In automotive production, these valves are utilized in systems that control the hydraulic functions of robotic arms and assembly equipment. Their ability to seamlessly integrate into existing systems further enhances their utility in this fast-paced industry. Aerospace applications benefit from their lightweight materials and compact design, allowing for sophisticated hydraulic systems that operate under extreme conditions while maintaining strict safety standards.

Moreover, in the field of renewable energy, particularly in wind and solar industries, Rexroth Modular Valves contribute to fluid control systems that help maximize the efficiency of energy conversion processes. Their durability also ensures long operational lifespans, a crucial factor when considering the investment in energy infrastructure. Venturing into newer markets, such as electric mobility, demonstrates the versatility and forward-thinking design of Rexroth Modular Valves, which align with the industry's demand for innovation.

Rexroth Modular Valves are characterized by their high precision, durability, and ease of integration. They are designed to withstand extreme conditions, providing consistent performance even in harsh industrial settings. These valves are available in various configurations, including flow control, pressure relief, and directional control types, thus offering comprehensive solutions for different requirements. The precision of these valves facilitates accurate control of fluid flow, which is essential in applications requiring exact hydraulic movements.

One of the distinguishing features of Rexroth Modular Valves is the ability to handle high pressures while maintaining low leakage rates, an essential attribute in hydraulic applications where fluid integrity is critical. Their sealing technologies have been engineered to minimize wear while enhancing operational efficiency, thereby reducing the frequency of replacement. The ease of integration of these valves with existing systems is facilitated by standardized dimensions and fastening methods, allowing for a straightforward installation process.

Rexroth has invested in employing advanced materials and surface treatments that not only enhance the life span of the valves but also maintain their functional integrity under varying environmental conditions. This foresight ensures that users can operate within a wide range of temperatures, pressures, and fluid types without compromising performance. Additionally, the innovative design allows for various control options such as electrohydraulic or manual operation, providing further flexibility in applications.

| Attribute | Rexroth Modular Valves | Traditional Valves |

|---|---|---|

| Modularity | Highly modular, customizable | Limited modularity |

| Durability | Designed for tough conditions | Varies by manufacturer |

| Integration Ease | Seamless integration | Complex integration process |

| Maintenance | Simplified maintenance | Complex and frequent |

| Customization | Highly customizable for specific tasks | Limited customization options |

| Control Options | Multiple control options available | Typically lower range of control |

| Performance Consistency | High consistency in performance | Performance may vary with use |

According to industry experts, the choice of hydraulic components significantly impacts system efficiency. Rexroth Modular Valves are praised for their ability to enhance automation systems' responsiveness and accuracy. This makes them a preferred choice in sectors where precision and reliability are non-negotiable. In the current industrial context, where automation is increasingly seen as a means to reduce costs and increase output, the role of hydraulic systems and their components cannot be understated.

Industries are under constant pressure to produce higher quantities while maintaining quality. Modular valves are essential in achieving this balance, as they can respond swiftly to changes in production requirements without necessitating lengthy downtime for equipment changes. Furthermore, the ongoing push for sustainability has led to the development of energy-efficient versions of these valves, contributing to an overall reduction in an operation’s carbon footprint.

Emerging technologies such as Industry 4.0 and the Internet of Things (IoT) further enhance the relevance of Rexroth Modular Valves. These technologies require components that not only perform but also communicate data effectively. Rexroth's commitment to digitalization has led to the development of smart valves capable of providing real-time feedback about their operational status, contributing to predictive maintenance and system monitoring solutions. Thus, Rexroth Modular Valves are not merely components in the hydraulic systems of the future; they are integral to the development of intelligent and interconnected manufacturing processes.

What are the benefits of using modular valves?

Modular valves offer customizable solutions, ease of maintenance, and adaptability, reducing operational downtime and costs while improving system efficiency. The flexibility to combine different modules based on application needs allows for personalized hydraulic system configurations.

How do Rexroth Modular Valves enhance industrial systems?

They provide precise fluid control, are easy to integrate into existing systems, and offer reliable performance even in challenging environments. Their ability to function seamlessly with automation technology further enhances their appeal in modern applications.

Are Rexroth Modular Valves suitable for all industries?

Yes, they are versatile and can be applied across various industries, particularly where precision, reliability, and adaptability are crucial. From heavy-duty applications in manufacturing to delicate operations in aerospace, their utility is broad and impactful.

What distinguishes Rexroth Modular Valves from traditional valves?

Rexroth Modular Valves stand out due to their modularity, which allows for greater customization and simpler maintenance. In contrast, traditional valves often come as monolithic units with limited modification capabilities, making them less adaptable to the rapidly changing needs of modern industries.

How has technology advanced the development of Rexroth Modular Valves?

Technological advancements have led to improved materials, precision engineering, and the introduction of smart components that enhance performance and facilitate predictive maintenance. These innovations allow for greater efficiency and reliability in various industrial applications.

In conclusion, Rexroth Modular Valves are integral to modern industrial operations, offering precision and flexibility. Their modular design enables personalized solutions that meet diverse industry needs, ensuring optimal performance and efficiency. As technology progresses, these valves will continue to play a pivotal role in advancing fluid control systems within industries around the globe. The ongoing innovation in valve technology, coupled with the demand for smarter and more adaptable industrial solutions, positions Rexroth Modular Valves at the forefront of hydraulic machinery advancements.

Future developments may also see further enhancements in the integration of software and sensors alongside these hydraulic components, allowing for even deeper insights and more efficient operations. As industries evolve, so too will the role of hydraulic systems and their components, and Rexroth Modular Valves are poised to lead the way. The consistent emphasis on sustainability, along with enhanced performance requirements, will ensure that these valves remain crucial in driving industrial performance across various sectors.

As we look to the future, the importance of hydraulic systems and their components like Rexroth Modular Valves will only continue to grow. Their ability to navigate the complexities of modern industrial challenges while providing reliable solutions ensures that they will be a cornerstone technology in achieving the next generation of automation and fluid control systems.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!