Rexroth Modular Valves play a pivotal role in the fluid control systems widely used in industrial applications. These versatile and efficient components are vital for optimizing hydraulic systems. In this comprehensive guide, we delve into their engineering marvels and explore their significance in enhancing operational efficiency.

Rexroth Modular Valves have emerged as indispensable components in the field of hydraulic and fluid control systems in various industrial applications. These valves are designed to facilitate precision control and energy efficiency, making them essential in optimizing processes across manufacturing, automobile, aerospace, and many other industries. With rising demands for automation and the need for sustainable solutions, the importance of these modular valves has grown exponentially. In this detailed discussion, we will explore their construction, functionality, and how they fit into the broader context of industry advancements.

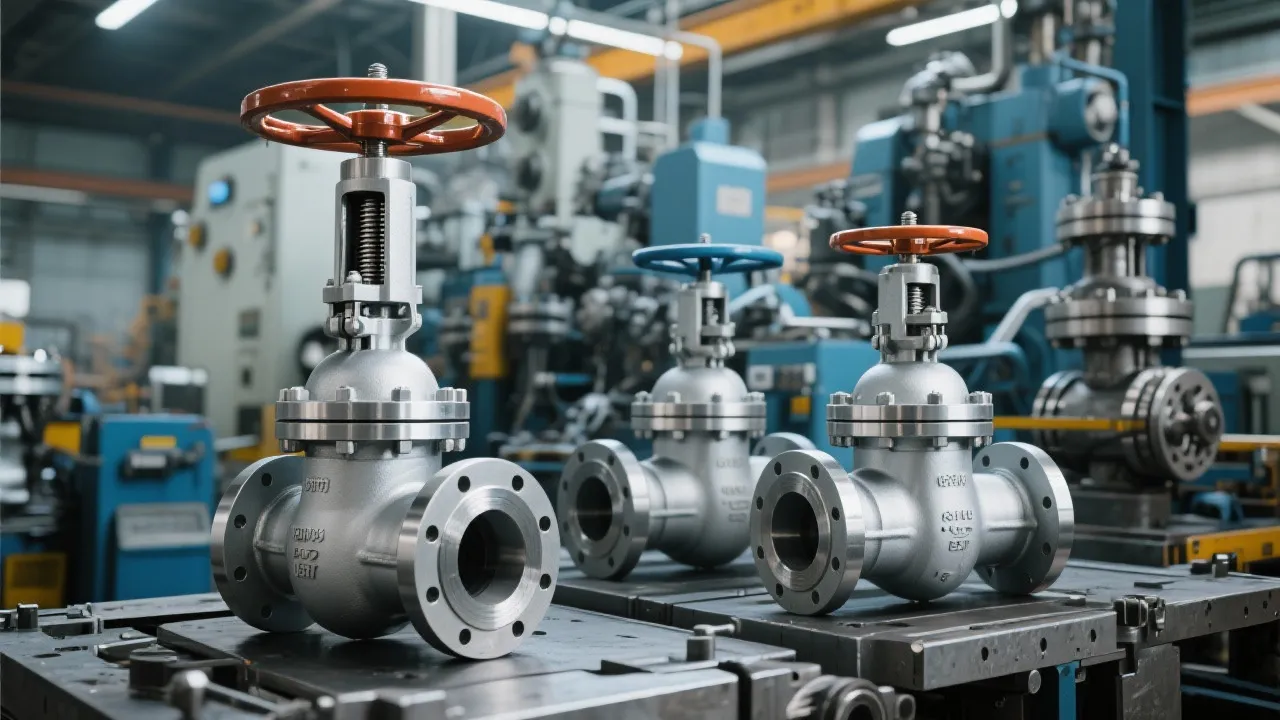

At the heart of an efficiently functioning hydraulic system are modular valves that provide flexibility and reliability. Rexroth, a leader in manufacturing sophisticated hydraulic components, engineers these valves to ensure superior performance. These valves are known for their modular design, allowing seamless integration into various configurations as per application requirements. This adaptability is crucial for industries where system demands frequently change.

To understand the intricacies of Rexroth Modular Valves, one must look beyond their external design. Internally, these valves are engineered for precision, featuring components that have been optimized for friction reduction and enhanced flow characteristics. The use of high-quality materials enhances their durability, making them withstand extreme operational conditions. Furthermore, manufacturers often provide essential tools and support for integration, ensuring that users can quickly adapt these valves to new systems or machinery.

The adaptability of Rexroth Modular Valves makes them suitable for various challenging applications, such as:

Beyond these sectors, Rexroth Modular Valves can also be found in renewable energy systems, food and beverage processing, and other critical utility services. Their versatility supports advanced industrial automation, crucial for maintaining a competitive edge in today’s economy.

Rexroth integrates cutting-edge technology in designing its modular valves. Features such as pilot-operated check valves, overpressure protection, and flow control adjustments are designed to enhance user control and safety. Furthermore, these technical innovations facilitate greater reliability across varying scenarios.

Advanced functionalities include:

Additionally, Rexroth emphasizes the importance of sustainability in their designs. Minimizing waste and maximizing efficiency not only serve immediate operational needs but also align with broader environmental goals. With a commitment to innovation, Rexroth is continually exploring new materials and technologies that reduce their ecological footprint.

| Model | Key Features | Typical Applications |

|---|---|---|

| R900561705 | Pilot-operated, high precision, low hysteresis | Automotive and aerospace systems, precision robotics |

| R900561696 | Energy efficient, flexible design, easy to integrate | Construction machinery and manufacturing, assembly lines |

This comparison helps industries quickly identify which valve suits their requirements based on specific features and application context. Understanding the nuances of each model can guide engineers and decision-makers in selecting the most appropriate system for their operational needs.

As the industry continues to evolve, Rexroth invests in research and development to stay at the forefront of hydraulic valve technology. The integration of Internet of Things (IoT) capabilities is a significant trend, allowing for even smarter systems where valves communicate with other machinery, track performance, and send alerts when maintenance is needed. This proactive approach not only enhances efficiency but also optimizes the operational infrastructures, potentially increasing lifecycle management.

Another area of focus is the advancement of materials used in manufacturing valves. Innovations in lightweight yet durable materials will further improve the energy efficiency and performance of these components, particularly in industries like aerospace where weight reduction is critical. Increasing pressure capabilities will also allow for the scaling up of operations without compromising safety standards.

Moreover, Rexroth is likely to place a greater emphasis on sustainability. The design of valves that not only minimize energy usage but also reduce fluid leakage through advanced sealing techniques is becoming crucial as industries focus on environmental responsibility. Ongoing collaborations with research institutions will help push these boundaries forward, ensuring that Rexroth Modular Valves remain relevant and highly efficient in tomorrow's industrial landscape.

Real-world applications demonstrate the significance and versatility of Rexroth Modular Valves across various sectors. Below are several case studies illustrating how these valves have improved operational efficiency and reliability.

In an automotive manufacturing facility, Rexroth Modular Valves were implemented in the assembly line to control robotic arms, which are critical for welding and painting processes. Before the installation, production bottlenecks were common, leading to delays and increased labor costs. By using high-precision Rexroth valves, the facility managed to improve the speed of the robotic operations while ensuring a higher quality of welds through consistent control.

The facility recorded a 25% increase in throughput within the first six months of implementation, significantly lowering the costs associated with delays and enhancing product quality. Operators reported less downtime due to the reliability of the Rexroth valves, which also reduced the need for frequent maintenance checks.

A leading construction equipment manufacturer faced challenges with hydraulic control in their excavators. Customers reported issues with valve responsiveness, especially during rapid movement. After consulting with Rexroth engineers, they integrated modular valves designed for high responsiveness and pressure control.

The changes eliminated delays in hydraulic power application, leading to more efficient operations on-site. Customer feedback reflected that the improved valve performance enhanced the machinery’s overall effectiveness, correlating to increased satisfaction and reduced complaint rates. This case underlines Rexroth’s commitment to solving real-world engineering challenges through innovative hydraulic solutions.

Rexroth Modular Valves exemplify the merger of technology and engineering expertise, catering to the needs of dynamic industrial functionalities. Whether you're looking into integrating hydraulic components or aiming to enhance system efficiency, exploring Rexroth's modular valves is highly recommended. As industries advance, incorporating such innovative components will be crucial in achieving sustainability and performance objectives. The ongoing evolution of these valves, alongside technological advancements in the industry, positions them as key players in the future of manufacturing and process automation. Adopting Rexroth’s modular solutions not only addresses immediate operational challenges but also aligns with long-term goals focused on efficiency, reliability, and sustainability.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!