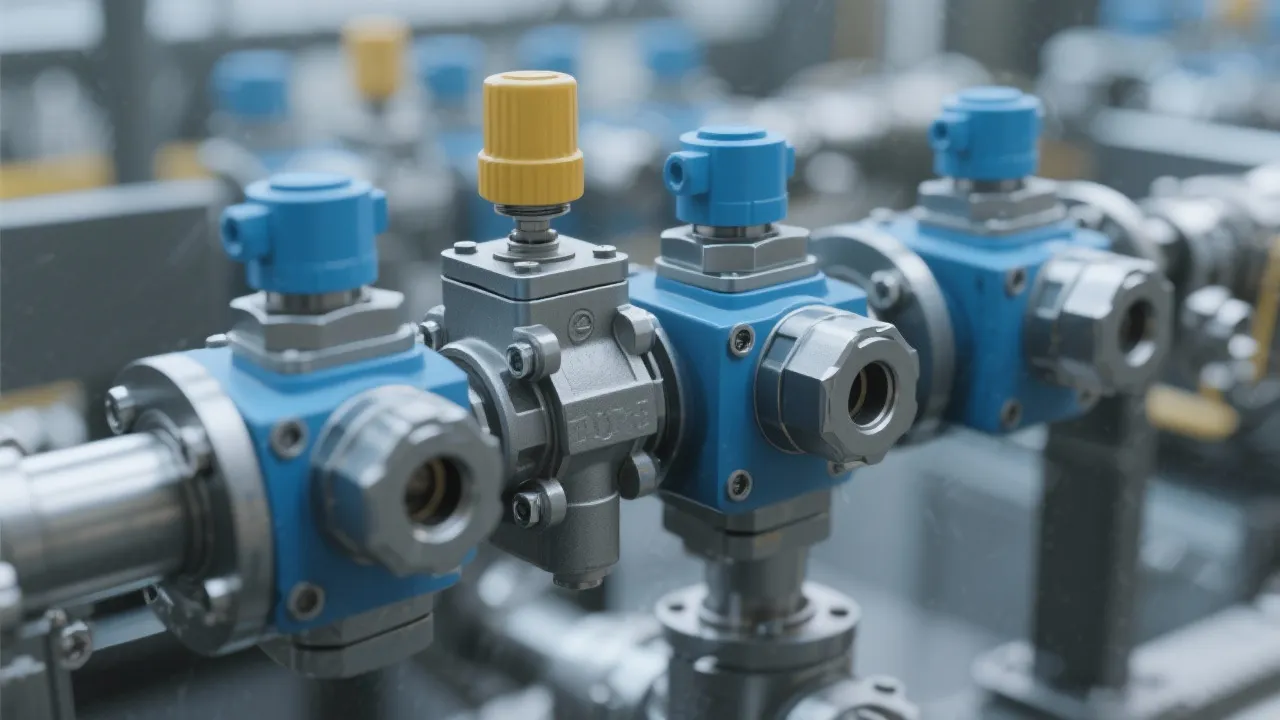

This guide delves into Rexroth Modular Valves and their significance in industrial applications. Rexroth, a prominent leader in hydraulic technology, offers modular valves designed to optimize efficiency, flexibility, and performance in various hydraulic systems. Modular valves are pivotal in managing pressure, flow, and direction in hydraulic circuits, making them indispensable in many sectors.

Industrial hydraulics have dramatically advanced due to innovations in modular valve design, notably those produced by Rexroth. Recognized globally, Rexroth Modular Valves are crafted to bolster operational efficiency, system versatility, and performance reliability. In industries where hydraulic systems are crucial, these valves stand at the forefront, influencing the trajectory of technological development. Modular valve systems represent a significant advancement in hydraulic engineering, allowing for innovative solutions tailored to meet the unique demands of various industries.

Modular valves have transformed hydraulic systems by offering a level of adaptability and optimization that traditional valves cannot match. The ability to customize and integrate valves within existing setups enhances system capabilities while minimizing downtime. Industries ranging from manufacturing to aerospace increasingly rely on Rexroth for cutting-edge solutions that ensure robust performance and cost-effective operational models. Furthermore, modular systems reduce maintenance complexity and downtime, allowing companies to maintain continuous operations, which is critical in high-stakes environments.

Rexroth Modular Valves serve several critical functions in hydraulic systems. Key roles include managing flow, controlling pressure, and directing fluid within the system. These valves find applications in construction machinery, marine technologies, and industrial automation. Their modular nature simplifies complex configurations, facilitating seamless adjustments tailored to specific industrial requirements without extensive redesigns. For example, in construction equipment, Rexroth Modular Valves can regulate the hydraulic flow to numerous hydraulic cylinders, providing precise control over lifting and digging operations, thereby enhancing productivity and safety on job sites.

One of the very compelling advantages of Rexroth Modular Valves is their adaptability. Industries can modify systems easily, responding to changes in operational demand or advancements in technology. Additionally, modular valves from Rexroth are designed with precision engineering, ensuring durability and extended service life, even in harsh operating environments. The ability to replace or upgrade individual valve modules instead of dealing with a whole system overhaul offers significant time and cost savings. This adaptability also allows for the integration of new technologies such as IoT and automation platforms, facilitating the evolution of smarter and more efficient systems within industrial settings.

| Aspect | Rexroth Modular Valves | Traditional Valves |

|---|---|---|

| Flexibility | Highly adaptable to system changes. | Limited adaptability; requires more system alterations. |

| Installation | Simplifies system integration. | Complex and time-consuming installation process. |

| Maintenance | Lower maintenance due to module-based repairs. | Higher maintenance needs from integral designs. |

| Cost-effectiveness | Good savings from reduced downtime. | Higher costs due to extensive overhaul requirements. |

| Technology Compatibility | Highly compatible with modern control systems. | Less compatibility with new technologies. |

| System Scalability | Easy to scale as operational needs grow. | Scaling often requires significant redesign. |

| Response Time | Faster response due to optimized flow paths. | Slower due to complex internal configurations. |

Before choosing the appropriate model, consider the system requirements, including flow rates, pressure levels, and the environment where the valves will operate. Understanding these parameters ensures optimal performance and longevity. Consult Rexroth's detailed product catalog or partner with a certified supplier to tailor solutions precisely to your industrial needs. Additionally, assessing the specific applications within your industry, such as high-speed production environments or extreme temperature conditions, can guide your selection process, ensuring that the chosen valves will operate effectively without compromising system integrity.

Recent industry reports highlight a growing trend towards modular hydraulic solutions. Rexroth, continuing its legacy of innovation, has led many of these advancements. Studies from reputable sources, such as the 'Journal of Hydraulic Engineering', underscore the increasing dependency of industries on reliable hydraulic solutions—wherein Rexroth Modular Valves play a pivotal role. The rising interest in automation and smart technologies has further propelled the demand for modular valves, as industries seek systems that can not only function independently but also communicate and integrate within larger networks of machinery and equipment.

Rexroth Modular Valves are employed in various industries, each presenting unique operational challenges and requirements. Below is an exploration of some prominent applications:

In construction, modular valves control hydraulic systems for excavators, bulldozers, and cranes. The challenges faced in these environments include high load capacities and the need for precise control during operations. Rexroth's solutions allow for adjustable flow rates, enabling dynamic responses to operator inputs and enhancing overall productivity. Furthermore, their ability to withstand extreme weather conditions makes them ideal for outdoor applications.

Marine applications require components that can endure harsh maritime environments. Rexroth Modular Valves are used in ship steering systems, winches, and other hydraulic-powered components. Their robust construction and resistance to corrosion ensure longevity and reliability, which are critical in marine operations.

Within industrial automation, Rexroth Modular Valves facilitate the seamless movement of materials and handling processes in manufacturing settings. Automated assembly lines rely on hydraulic systems for various functions, from lifting heavy components to maneuvering robotic arms. The modular design allows for rapid adaptability and scalability, accommodating changes in production processes without significant investments in new equipment.

In aerospace, precision is paramount. Modular valves from Rexroth are integrated into landing gear systems and flight control mechanisms, where precise pressure and flow control are necessary. The lightweight and compact designs of these valves complement the aerospace industry's demands for efficiency and performance while ensuring safety and reliability across all operations.

As industries evolve, the integration of smart technologies with Rexroth Modular Valves becomes increasingly important. With the rise of Industry 4.0, these valves are now fitted with sensors and smart controls that allow real-time monitoring and predictive maintenance capabilities. This integration helps operators to maintain system efficiency and reduce downtime through timely interventions.

IoT (Internet of Things) technology enhances valve functionality by enabling remote monitoring and control. Operators can analyze data in real time, allowing for better decision-making based on operational conditions. This technological advancement allows for proactive maintenance schedules rather than reactive ones, significantly extending the lifespan of hydraulic systems.

Rexroth’s modular valves can be seamlessly integrated with automation platforms, enhancing overall operational efficiency. By utilizing digital signal processing techniques combined with robust software applications, operators can program complex control algorithms that adapt to fluctuating operational demands, ensuring precision and reliability.

To fully leverage the benefits of Rexroth Modular Valves, a proactive maintenance strategy is essential. Below are recommended best practices to ensure optimal performance:

Conducting routine inspections allows for the early detection of wear and potential issues within the hydraulic system. Checking for leaks, unusual noises, and pressure inconsistencies can inform timely repairs and prevent larger malfunctions.

Keep the valves clean and ensure that all moving parts are adequately lubricated. Contaminants within the hydraulic fluid can lead to performance issues and should be minimized through filter use and regular fluid changes.

Training personnel operating hydraulic systems is vital to avoid misuse or incorrect operation of these sophisticated components. Ensuring that staff understand the functionality and maintenance requirements of Rexroth Modular Valves will promote better management and reduce costly errors.

What makes Rexroth Modular Valves stand out?

The standout factor is their modular design, which offers unmatched flexibility and efficiency in system integration and maintenance. Their adaptability allows for tailored solutions in various industrial applications, which is essential for meeting diverse operational challenges.

Are Rexroth Modular Valves suitable for all industries?

While they are especially beneficial in heavy-duty and environmentally challenging industries, their versatility makes them suitable across various sectors. From high-speed manufacturing to outdoor construction environments, the design of Rexroth Modular Valves caters to specific needs, ensuring reliable performance wherever they are installed.

What maintenance practices ensure optimal longevity of these valves?

Regular inspections, adhering to manufacturer guidelines, and utilizing certified parts for repairs can significantly extend valve lifespan. Additionally, incorporating predictive maintenance practices and utilizing IoT monitoring solutions can proactively identify issues before they escalate.

How does the pricing of Rexroth Modular Valves compare to traditional valves?

Although initial costs may be higher, their low maintenance needs and reduced downtime often result in cost savings over the long term. The overall value provided by the adaptability and longevity of Rexroth Modular Valves justifies the investment in many industrial applications.

Rexroth Modular Valves remain essential in reimagining hydraulic systems' efficiency and capability. As industries pursue innovation, these valves are an integral part of the evolution, offering unparalleled benefits through their adaptable and reliable design. Whether enhancing existing systems or developing new technologies, the strategic integration of modular valves stands as a testimony to Rexroth's commitment to excellence in hydraulics. Their future-ready approach positions them as leaders in facilitating the next-generation hydraulic solutions, ultimately driving advancements across diverse sectors and contributing to the ever-evolving landscape of industrial technology.

As we look ahead, the role of Rexroth Modular Valves within hydraulic systems is poised to grow in significance. Companies are increasingly seeking solutions that not only address current operational challenges but also incorporate sustainability and energy efficiency. The shift towards eco-friendly practices in industries is influencing the design and usage of hydraulic components, and Rexroth is at the forefront of these developments.

Rexroth is focusing on creating valves that align with green operation criteria. Innovations such as energy-efficient hydraulic circuits can minimize energy consumption and reduce carbon footprints. Furthermore, the ability to finely control fluid dynamics further enhances operational efficiency, promoting less waste and better resource management in industrial applications.

The future landscape of hydraulic systems will heavily feature smart technologies. Rexroth is exploring advancements in artificial intelligence and machine learning, which can further optimize the performance of modular valves. The potential for digital twins—virtual simulations of physical assets—can enable users to assess predictive performance, making maintenance and operational strategies more efficient and effective.

In summary, Rexroth Modular Valves are more than just components of hydraulic systems; they represent a profound shift in how industries approach hydraulic solutions. Their modular nature, adaptability, and integration of modern technologies ensure that they will remain a cornerstone in the evolution of industrial hydraulics. As companies increasingly look for versatile, durable, and efficient solutions to meet the demands of a rapidly changing business environment, Rexroth's commitment to innovation positions them as a key player in driving forward the future of hydraulic technology.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!