Rexroth Cartridge Valves represent a pinnacle in hydraulic control, known for their efficiency and reliability. These valves play a crucial role in various hydraulic systems, offering modularity and precision. Discover the benefits, design features, and applications of Rexroth Cartridge Valves in this comprehensive guide.

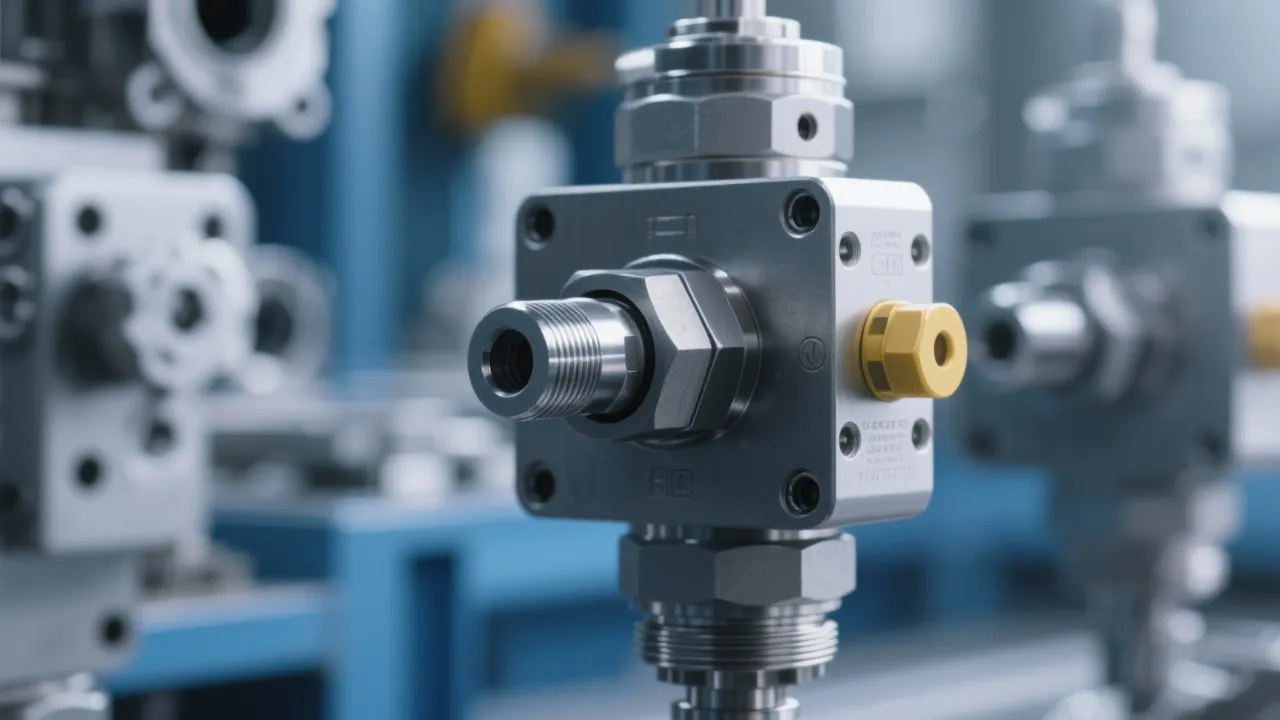

Rexroth Cartridge Valves, integral components of hydraulic systems, are celebrated for their precision and reliability. Designed to regulate fluid flow and pressure, these valves are essential for maintaining optimal performance in a variety of industries, including manufacturing, mining, and construction. With their modular design, Rexroth Cartridge Valves offer exceptional flexibility in system design and implementation. The engineered expertise behind these valves ensures that they not only meet industry standards but often exceed them, providing significant advantages in operational capabilities.

At the core of their robust functionality is the unique design of Rexroth Cartridge Valves. These valves are constructed to enable seamless integration into complex hydraulic systems, allowing for efficient control over fluid dynamics. The thoughtful design reduces the likelihood of fluid leakage and maximizes operational efficiency, which is critical in high-stakes industrial environments. Designed to adapt to a wide range of pressure, flow rates, and media, Rexroth Cartridge Valves can be finely tuned to meet specific application demands.

The versatility of Rexroth Cartridge Valves allows them to be used in a wide range of applications. In construction, they control heavy lifting equipment’s hydraulics, ensuring safety and reliability. For example, hydraulic excavators utilize these valves to deliver precise movements, enhancing efficiency and minimizing operator fatigue. Manufacturing processes benefit from their high precision, which is vital for automation systems requiring exact fluid control, such as in robotics and assembly lines. The mining industry relies on these valves for operating heavy machinery under demanding conditions where durability is paramount, reducing downtime and maintenance costs.

| Industry | Application Example | Benefit |

|---|---|---|

| Construction | Hydraulic excavators | Enhanced control and safety, allowing operators to perform complex tasks effectively. |

| Manufacturing | Automated production lines | Precision in operation that increases throughput and reduces the cost of errors. |

| Mining | Heavy machinery operation | Reliable performance under high pressure, increasing operational efficiency and safety. |

Selecting the appropriate Rexroth Cartridge Valve depends on various factors such as system requirements, environmental conditions, and specific industry needs. Understanding the hydraulic system's parameters, including fluid type, viscosity, and pressure, is crucial in choosing the correct valve. Consulting with a specialist can provide insights into which valve model will offer the top performance benefits for your particular application. Additionally, assessing future scalability needs is essential, ensuring that the chosen valve can grow with the operational demands.

Regular maintenance is crucial to keep Rexroth Cartridge Valves functioning optimally. Routine checks should include inspecting for signs of wear and ensuring all connections are secure. Common issues such as leaks can often be traced back to seals, which may need replacing due to wear or contamination. Additional troubleshooting steps involve checking for blockages in the hydraulic lines, validating that the valve is correctly aligned, and ensuring that no external factors are adversely impacting performance, such as electrical failures or software issues in electronically controlled systems.

In cases of malfunction, common solutions include:

Beyond their established competence, Rexroth has consistently evolved its cartridge valve technology to incorporate advanced features aimed at enhancing the efficiency and usability of hydraulic systems. Some of the significant advancements include the integration of smart technology, which allows for remote monitoring and diagnostics. By implementing IoT (Internet of Things) principles, users can gain real-time insights into valve performance metrics, allowing for predictive maintenance that minimizes unscheduled downtimes and improves the overall system reliability.

Furthermore, the development of eco-friendly materials in the manufacturing of cartridge valves plays a crucial role in promoting sustainability in industrial practices. By adopting lighter yet equally durable materials, such as composites and recyclable metals, manufacturers are able to reduce the overall environmental impact of hydraulic systems. These innovations eschew traditional materials in favor of options that do not compromise performance but significantly lessen ecological footprints.

Looking ahead, several trends will likely shape the future of Rexroth Cartridge Valves and their application in industries:

Rexroth Cartridge Valves represent the epitome of reliable hydraulic control. Their sophisticated design and outstanding performance make them indispensable in demanding industries. As technology advances and operational needs continue to evolve, these valves will undoubtedly remain at the forefront of hydraulic innovation, driving efficiency and performance in various applications worldwide.

The implications of Rexroth Cartridge Valves extend beyond individual industries and applications; they contribute significantly to global economic productivity and environmental sustainability efforts. Efficient hydraulic systems translate into faster project completions and reduced resource consumption. For instance, in large-scale construction projects, leveraging advanced hydraulic systems with high-quality cartridges decreases the time it takes to build and increases the safety of operations. As a result, societies benefit from improved infrastructure and job creation while minimizing the strains on environmental resources.

Furthermore, Rexroth’s commitment to sustainability, through both product innovation and responsible manufacturing practices, aligns with global initiatives aimed at reducing carbon footprints. These efforts resonate well with international regulatory pressures for emissions reductions and responsible resource usage. As industrial players respond to these pressures, implementing robust hydraulic solutions like Rexroth Cartridge Valves positions them not only as leaders in their fields but also as contributors to a more sustainable future.

To maximize the potential of Rexroth Cartridge Valves within various industries, education and training are paramount. Technical training programs focusing on hydraulic systems maintenance, valve operation, and system design can equip personnel with the necessary skills and expertise. Rexroth and similar companies often provide training modules for technicians and engineers, helping to bridge knowledge gaps and improve overall competency in hydraulic technologies.

Additionally, educational institutions can play a vital role in preparing students for careers in industries reliant on hydraulic systems. By fostering collaborations between industry leaders like Rexroth and educational entities, students can gain hands-on experiences that enhance their understanding of hydraulic systems and their components, leading to a more skilled workforce ready to meet ongoing and future challenges in the field.

In conclusion, Rexroth Cartridge Valves serve as foundational components within hydraulic systems that power critical machinery across various industries. Their exceptional performance, reliability, and innovative design make them a top choice for engineers and operators alike. As industries evolve and face new challenges, the role of these valves will only increase in importance, thereby necessitating ongoing developments in technology and operator education to ensure the highest levels of efficiency and effectiveness. Continued investment in Rexroth Cartridge Valves is not merely a matter of choice but a critical component in driving future industrial success.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!