Rexroth Modular Valves are critical components in hydraulic systems, providing precise fluid control and automation. These valves are versatile, offering various configurations for different industrial applications. Rexroth's innovation in this domain helps enhance system efficiency and reliability, making it a trusted choice for engineers and technologists alike.

Rexroth Modular Valves form the backbone of many modern hydraulic systems, catering to diverse industrial requirements with their adaptability and precise performance. At the core, these valves facilitate the controlled movement of fluids, which is vital for the smooth operation of machinery in industries ranging from automotive manufacturing to large-scale construction projects. This introduction serves as a basis to delve deeper into the technological advancements, practical applications, and benefits of Rexroth Modular Valves, highlighting why they are considered a critical component across various sectors.

In today's fast-paced industrial landscape, the need for efficiency and precision in fluid control cannot be overstated. Modular valves from Rexroth provide flexibility and scalability, allowing engineers to design systems that can be easily adjusted to meet specific operational demands. These valves ensure optimal flow and pressure control, which are critical in maintaining the safety and efficiency of hydraulic systems. As we explore further, we will see how these characteristics contribute to productivity and operational excellence in diverse settings, from automated assembly lines to complex machinery in heavy industries.

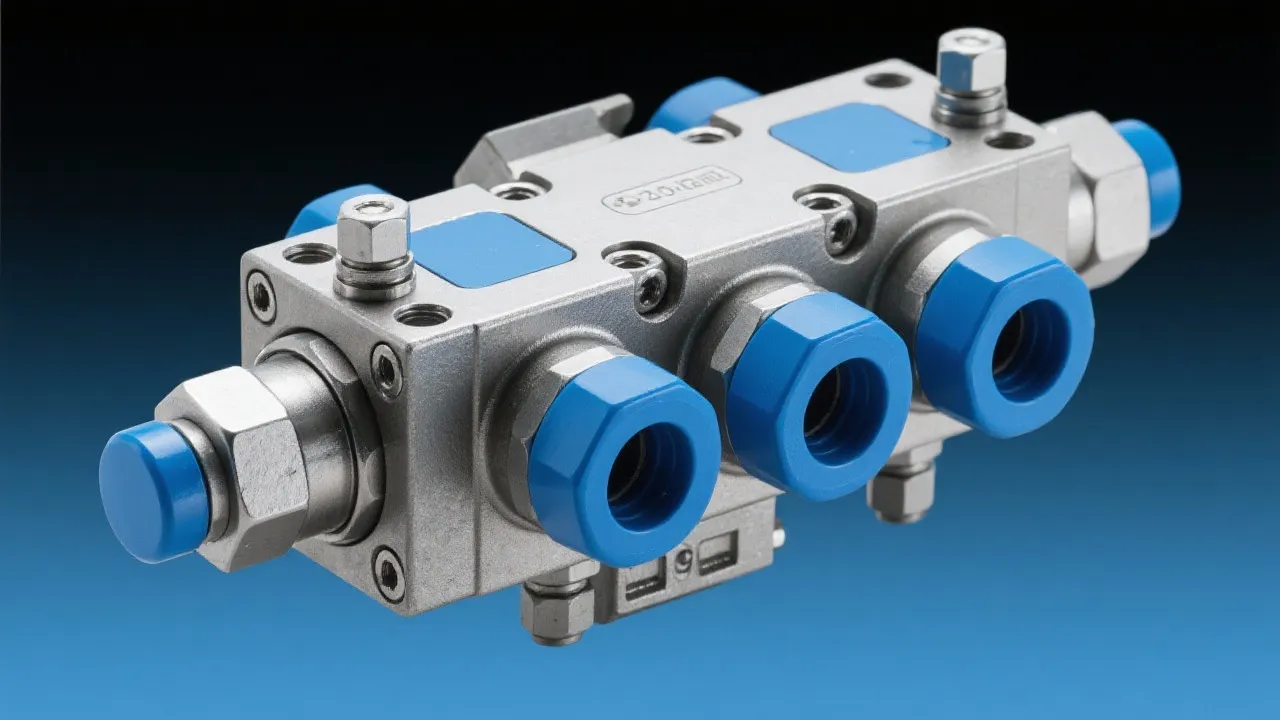

Rexroth modular valves are built on a block system concept, which allows for the customization of circuit functions without the need to redesign entire systems. The modularity supports the integration of various functional elements, such as pressure relief, check valves, and flow control mechanisms, into compact and efficient units. Individual valves can be combined in myriad configurations, making them suitable for various applications.

The technical design of these valves often incorporates hydraulic and electronic control technologies that enhance performance. Additionally, Rexroth modular valves are equipped with features such as anti-cavitation and load sensing, which improve operational efficiency. Understanding the technical capabilities of these valves underlines their relevance in modern hydraulic applications.

| Valve Type | Description |

|---|---|

| Directional Control | Makes use of a spool to direct fluid between hydraulic pumps and actuators. This ensures that the hydraulic power is directed precisely where it is needed, enhancing responsiveness in operating machinery. |

| Pressure Control | Maintains system pressure for safe and effective operation, preventing over-pressurization that could lead to equipment failure or safety hazards in a hydraulic circuit. |

| Flow Control | Regulates the speed and volume of hydraulic fluid moving through the system, allowing for smoother operation and improved machine performance. |

| Check Valves | Prevent backflow in hydraulic lines, ensuring that fluid flows in one direction only, thereby protecting the integrity and reliability of the system. |

| Relief Valves | Automatically relieve pressure when it exceeds a predetermined threshold, safeguarding hydraulic components from excessive pressure that might cause damage. |

| Flow Meters | Measure the flow rate within the hydraulic system, providing feedback that is crucial for system management and efficiency enhancements. |

| Electrohydraulic Valves | Combine hydraulic performance with electronic control for highly responsive actuation that can be finely tuned to specific operating parameters. |

One of the leading benefits of Rexroth Modular Valves is their robust design. Engineered with high-grade materials, they offer durability even in harsh operating conditions. These materials resist wear, corrosion, and fatigue, ensuring longevity and reliable operation. Moreover, the modular nature allows for simplified maintenance and upgrades, reducing downtime and maximizing productivity.

Additionally, the compact design of Rexroth modular valves translates into space savings in machinery layouts. This is particularly advantageous in environments where every square inch of workshop or factory floor space must be optimized. The interconnected valve blocks can be arranged in various configurations to suit installation requirements, thereby enhancing versatility in hydraulic system design.

Another significant advantage is the reduced need for extensive piping. Since these valves can be connected directly through their modular system, there is less complexity and fewer potential leak points in the hydraulic circuit. By minimizing the number of connections and components, engineers can create more efficient systems that work at optimal levels.

Installation of Rexroth modular valves is straightforward due to their unitized construction. The modular design allows for quick assembly and reconfiguration, which reduces installation times significantly. Technicians can install a complete valve set-up with minimal tools and expertise, making it accessible even for teams not extensively trained in hydraulic systems.

Once installed, regular maintenance, such as cleaning of block interfaces and checking for wear and tear, can significantly extend the life of the valves. This proactive maintenance approach can prevent costly breakdowns and disruptions in operations. Further, because the modules can often be replaced individually, maintenance does not necessitate shutting down the entire hydraulic system, thus minimizing productivity losses.

Professional training for operators can enhance service efficiency and improve response times in the event of malfunctions. A well-informed workforce can quickly identify and address potential issues before they escalate, ensuring that equipment remains operational and efficient. Many Rexroth distributors and service centers provide training programs designed to equip personnel with the necessary skills and knowledge to maintain hydraulic systems effectively.

As technology advances, so too does the design and functionality of Rexroth modular valves. Innovations such as the integration of IoT (Internet of Things) technology have paved the way for smarter hydraulic systems. By connecting valves to a cloud-based system, operators can monitor performance in real-time, gaining insights into pressure levels, flow rates, and maintenance needs.

A prime example of this innovation is the ability to conduct predictive maintenance, where data analytics identify patterns indicative of future failures. This allows companies to schedule maintenance proactively rather than reactively, drastically reducing unplanned downtime and maintenance costs.

Additionally, advancements in materials science have resulted in components that can withstand more extreme temperatures and pressures, further broadening the operational envelope of hydraulic systems. These advancements empower industries that operate under severe conditions to utilize hydraulic solutions where they might not have previously been deemed feasible.

Q: What industries benefit greatly from using Rexroth Modular Valves?

A: Industries such as automotive, aerospace, manufacturing, and construction heavily depend on Rexroth Modular Valves due to the precise flow and pressure control required in their operations. These valves are widely used in assembling machinery, construction vehicles, and aerospace components, where reliability and performance are paramount.

Q: How do Rexroth Modular Valves contribute to environmental sustainability?

A: By optimizing hydraulic system efficiency, these valves reduce energy consumption and minimize hydraulic fluid waste, supporting environmentally friendly industrial practices. Moreover, manufacturers can design systems with smaller hydraulic units that utilize less energy to achieve the same performance, thus lowering the overall carbon footprint.

Q: Can these valves be customized for specific applications?

A: Yes, the modular design allows for significant customization to meet unique operational needs, ensuring compatibility with existing system architectures. Engineers have the flexibility to mix and match components based on specific requirements, making these valves suitable for a broad range of industrial applications.

Q: Are Rexroth Modular Valves suitable for high-frequency applications?

A: Absolutely. Rexroth modular valves are designed to handle rapid cycling and high-frequency operations. They maintain performance accuracy and efficiency even under demanding conditions. Industries like robotics and automated production lines, which require quick and precise actuation, benefit significantly from this feature.

To illustrate the versatility and efficacy of Rexroth modular valves, consider their application in an automotive manufacturing plant. In this scenario, the plant utilizes advanced robotic systems for assembly tasks. Each robotic arm requires precise hydraulic control to operate effectively, from moving components to applying torque during tightening operations. The engineers chose Rexroth modular valves to configure a hydraulic system that not only meets these precise control requirements but also allows for future enhancements.

The modular design facilitated an initial configuration that supported the existing machinery while allowing for additional modules to be integrated as new robots were added to the assembly line. As production demands increased, the facility expanded its hydraulic capabilities without needing a complete system overhaul, demonstrating how Rexroth modular valves can adapt to changing operational needs.

This case further emphasizes the benefits of reducing lead times and lowering overall costs while maintaining optimal performance levels throughout production. The plant's system experienced a noticeable improvement in efficiency, contributing to overall productivity gains while also meeting the stringent quality standards expected in the automotive industry.

Rexroth Modular Valves offer unparalleled flexibility and reliability, making them indispensable in hydraulic system design. Their robust and adaptive nature not only enhances productivity but also ensures sustainable operations across various industries. As technology and industrial needs continue to evolve, Rexroth remains at the forefront, innovating to meet the expanding demands of fluid control systems. With continuous improvements in technology, materials, and system integration, the future of Rexroth modular valves looks promising, paving the way for further advancements in hydraulic applications and efficiency.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!