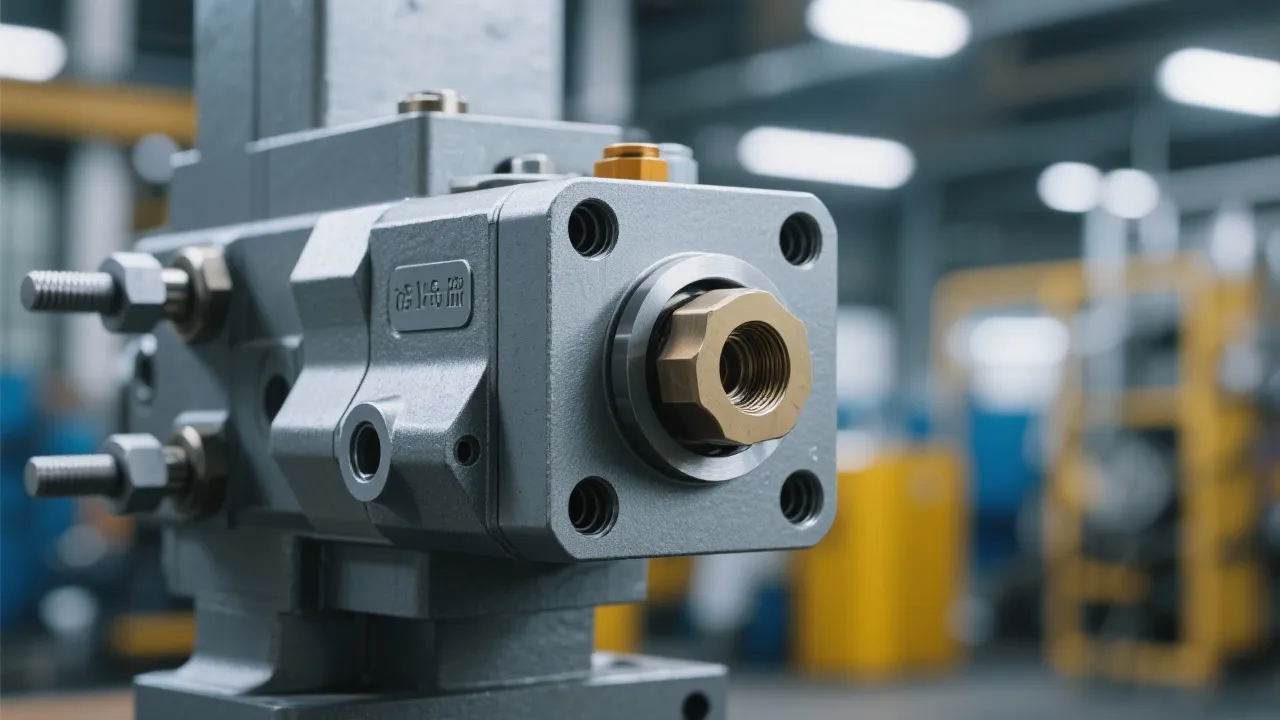

Hydraulic Cartridge Valves play a crucial role in fluid power systems by controlling flow and pressure. Previously considered niche components, they are now essential in various industries, including construction and manufacturing. This article explores their functions, advantages, and applications, providing insights into their growing significance in engineering and industrial contexts.

Hydraulic Cartridge Valves are indispensable in modern industrial and construction machinery. These components control the movement and pressure of hydraulic fluid, ensuring the seamless operation of complex systems. Known for their compact nature and high efficiency, they facilitate fluid regulation in applications that require precise control and reliability. The following sections explore the evolution, advantages, applications, and future of these critical components in the realm of hydraulic systems.

Historically, the use of hydraulic systems can be traced back to ancient civilizations leveraging water channels for operations. Early examples include hydraulic lifts and primitive waterwheels. However, the modern development and integration of Hydraulic Cartridge Valves have significantly increased efficiency and adaptability in fluid power systems, particularly during the industrial revolution which saw an explosion in machine technology.

The introduction of hydraulic systems revolutionized how machines were operated, moving from manual power to using fluid dynamics to transmit power. This shift has led to the evolution of various components adept at performing specific functions, with hydraulic cartridge valves being a standout innovation due to their ability to combine multiple functionalities into one compact unit.

These valves offer easy integration into different environments, making them vital in industries such as agriculture, aeronautics, and manufacturing. In agriculture, for instance, their ability to function in extreme conditions ensures farmers can reliably operate machinery like tractors and harvesters regardless of environmental challenges. In aeronautics, they support precision in flight control systems, showcasing their versatility and critical importance in various applications.

There are several reasons why Hydraulic Cartridge Valves are preferred over traditional valve systems:

The versatility of Hydraulic Cartridge Valves allows them to be used in a myriad of industries, transforming the way operations are conducted:

Industry reports consistently emphasize the growing demand for Hydraulic Cartridge Valves due to advancements in industrial automation. According to the International Fluid Power Society, their usage is expected to grow by over 7% annually, reflecting the increasing reliance on efficient and reliable fluid control systems. This trend is backed by a global shift towards automation across several sectors to improve productivity and reduce labor costs.

Moreover, research indicates that the push for sustainable energy solutions has also spurred innovations in hydraulic technology, including the development of hydraulic systems that incorporate energy-saving features. Experts indicate that cartridge valves that support regenerative hydraulic systems are becoming popular in mobile machinery, further enhancing their role in future applications.

The growing electric vehicle market also presents new opportunities for hydraulic cartridge valves, particularly in hybrid and electric systems where hydraulic systems stabilize dynamic movements. Manufacturers are beginning to develop specialized hydraulic cartridges designed specifically for this evolving sector, promising advancements in both performance and efficiency.

| Industry | Application |

|---|---|

| Construction | Excavators, bulldozers |

| Agriculture | Combine harvesters, irrigation systems |

| Manufacturing | Injection molding, hydraulic presses |

| Aerospace | Flight control systems, hydraulic brakes |

| Marine | Steering, deck machinery |

The future of Hydraulic Cartridge Valves is bright and promises to be influenced by several factors as technological advancements continue to reshape industrial standards. One prominent trend is the integration of smart technology into hydraulic systems. With IoT (Internet of Things) becoming more prevalent, developers are starting to incorporate sensors and connectivity into hydraulic cartridge designs. This enables real-time monitoring and predictive maintenance, significantly reducing the risk of system failures and downtime.

Another trend is sustainability. As industries are pressured to minimize their environmental impact, hydraulic manufacturers are focused on reducing fluid leakage and energy consumption. This is crucial in applications such as mobile machinery, where efficiency can lead to significant reductions in greenhouse gas emissions. Manufacturers are innovating hydraulic cartridge designs that use bio-degradable fluids; thus, even if leaks occur, they pose less risk to the environment.

Furthermore, advancements in materials science are leading to the development of more robust materials that resist wear and corrosion, extending the life of hydraulic cartridges significantly. These innovations not only help reduce replacement costs but also enhance safety by ensuring consistent performance over extended periods.

Finally, international standards are evolving, making it necessary for hydraulic cartridge valves to meet stricter regulations about emissions, safety, and performance. Manufacturers that can adapt to these changes quickly will have a competitive advantage in the marketplace.

Hydraulic Cartridge Valves have become pivotal components in various sectors thanks to their compact design, flexibility, reliability, and efficiency. As industries continue to evolve with technological advancements, the role of these valves is expected to expand, underscoring their importance in engineering and industrial applications. Whether in construction, agriculture, or manufacturing, the impact of hydraulic cartridge valves is profound, driving efficiency and productivity across diverse operations.

With innovation at the forefront and an increasing push toward sustainable practices, the future of Hydraulic Cartridge Valves looks promising. Embracing new technologies and materials is crucial, and as they adapt to meet the changing demands of modern industries, these valves are set to play an ever-greater role in the evolution of hydraulic systems.

As the world leans more towards automation and interconnectedness, the ability of hydraulic cartridge valves to integrate seamlessly into modern equipment will ensure they remain a staple in the toolkit of engineers and technicians. This continued relevance is a testament to their design and adaptability, making them a crucial component in future industrial advancements.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!