Hydraulic cartridge valves are integral components in fluid power systems, designed to control flow and manage pressure within hydraulic circuits. Highly efficient and compact, they cater to diverse industrial needs ranging from construction machinery to automotive applications. This guide explores their workings, benefits, and the latest advancements, while also offering answers to common inquiries on maintenance and selection.

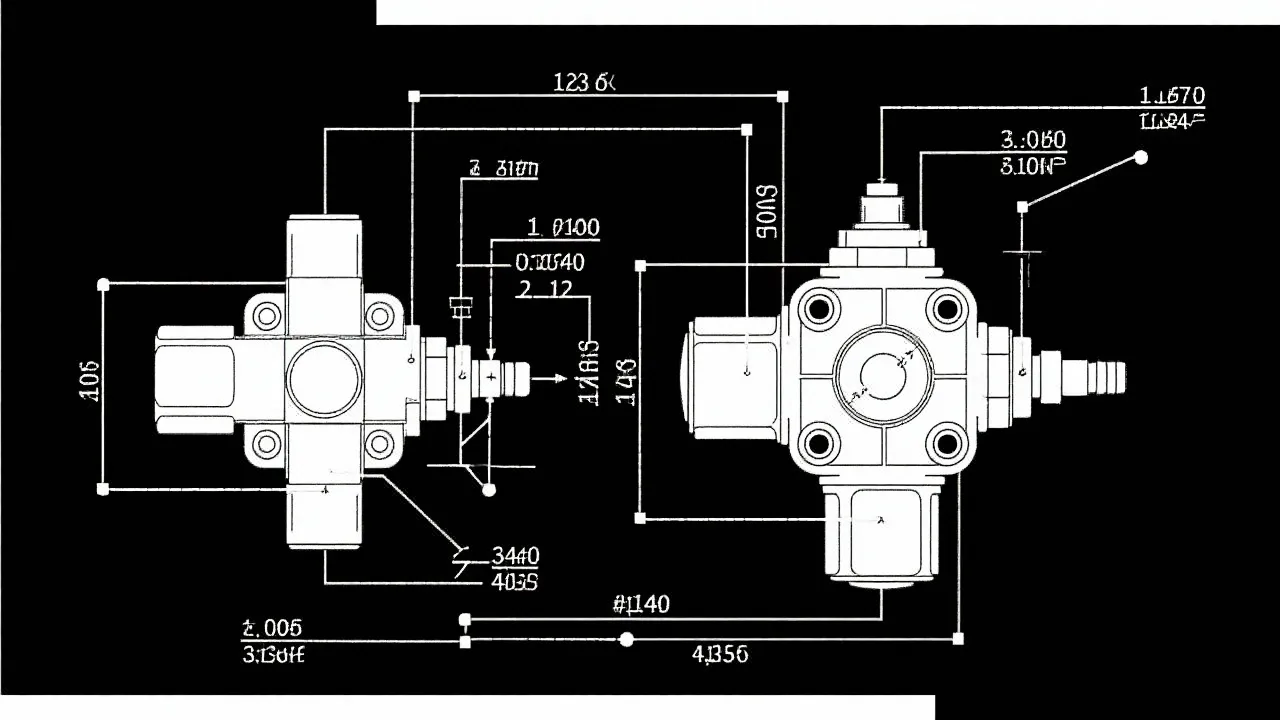

Hydraulic cartridge valves are cornerstone components in modern hydraulic systems, revered for their efficiency, space-saving configuration, and versatile application across various industries. Primarily used to control fluid flow and pressure, these valves serve an integral role in systems where precision and reliability are paramount. Their ability to be integrated into a compact manifold system allows for a simplified design that not only optimizes space but also enhances the overall effectiveness of the hydraulic system.

Hydraulic cartridge valves offer numerous benefits, including streamlined design and ease of maintenance, aiding in the reduction of system complexity. They can be integrated into a manifold rendering fluid circuits compact and efficient. This compact integration minimizes the number of external connections, thereby reducing the potential for leaks and improving system reliability. Additionally, the design of these valves allows for modular construction, where valves can be easily replaced or upgraded without the need for extensive rework of the hydraulic circuit, further enhancing system uptime and reducing maintenance costs.

The principal functions of hydraulic cartridge valves include directional control, flow control, and pressure regulation.

With evolving technology, hydraulic cartridge valves have seen significant enhancements in durability and control accuracy. Modern designs emphasize energy efficiency, lessening environmental impact while fulfilling stringent industrial standards. For instance, the implementation of **micro-honing** techniques significantly improves the smoothness of valve surfaces, decreasing friction and wear over time, which translates to longer service intervals and reduced maintenance costs.

Moreover, **digital integration** in the form of smart valve solutions allows for real-time performance monitoring and analytics. These intelligent systems can adjust valve behavior based on operational feedback, optimizing performance dynamically and improving overall system efficiency. Advancements like these are prompting industries to adopt more sophisticated hydraulic technologies, which in turn drives innovation further as manufacturers respond to evolving customer needs.

Choosing the right hydraulic cartridge valves is crucial for system performance. Below are some key considerations to keep in mind when selecting these components:

| Consideration | Details |

|---|---|

| System Pressure | Ensure compatibility with system pressure requirements to avoid malfunction and ensure safety. Oversized valves can lead to loss of efficiency, while undersized valves may cause system failure. |

| Flow Rate | Valves must accommodate the potential flow rate to maintain optimal function. Assessing system demands during peak operational periods will aid in selecting the suitable valve size and type. |

| Environment | Consider the operating environment, including temperature and exposure to elements, to ensure material suitability. Corrosion resistance may be vital in certain industrial applications, like marine or chemical processing. |

| Application | Specific applications may demand specialized valve designs for optimal performance. Factors such as load characteristics, cycle frequency, and system layout should all be factored into the decision-making process. |

Despite their extensive use, adopting hydraulic cartridge valves involves obstacles such as integration issues, potential leaks, and the necessity for trained personnel. One common hurdle is ensuring correct installation and configuration within the hydraulic system. Misalignment or incorrect assembly can lead to performance degradation or operational failures.

Routine checks and maintenance are vital to ensuring uninterrupted operation and longevity of the systems. Identifying early signs of wear or fluid contamination can prevent more significant issues down the line. Additional complexity arises from the need for skilled technicians who can understand the nuances of modern hydraulic systems. Investing in training and utilizing comprehensive service manuals can mitigate these challenges and ensure ongoing operational efficiency.

1. How often should hydraulic cartridge valves be maintained?

Routine inspection and maintenance are recommended monthly, with more comprehensive servicing performed annually or bi-annually depending on usage conditions. Additionally, any signs of wear or performance issues should be addressed immediately, regardless of the established maintenance schedule.

2. Can hydraulic cartridge valves be customized?

Yes, customization is possible. Manufacturers provide options to tailor valves to specific industrial applications. Customization can involve altering size, flow characteristics, and even integration with automation systems to enhance compatibility with existing machinery.

3. What industries benefit the most from hydraulic cartridge valves?

These valves are essential in construction, automotive, aerospace, and manufacturing sectors due to their reliability, precision, and efficiency in varied conditions. Additionally, industries such as mining, agriculture, and energy production are increasingly adopting hydraulic cartridge valves to enhance performance and reliability in their operations.

As industries continue to push for higher performance, lower emissions, and greater efficiency, the future of hydraulic cartridge valves is closely tied to advancements in technology and materials. Research and development efforts are leaning towards creating valves that not only perform better but are also more sustainable.

One emerging trend is the use of advanced materials such as composites and smart alloys that can withstand extreme conditions while maintaining weight and performance. Furthermore, the integration of sensors and IoT technologies can transform traditional hydraulic systems into predictive maintenance systems, providing real-time insights into valve health and system performance.

Moreover, as automation becomes more prominent in industries worldwide, hydraulic systems will increasingly leverage adaptive control strategies. This will enable the development of self-regulating hydraulic systems that can adjust in real-time to changes in operational conditions, thereby optimizing performance and energy consumption. With these advancements, the role of hydraulic cartridge valves will expand, proving them to be a vital element not just in conventional applications but also in innovative and emerging technologies.

Overall, hydraulic cartridge valves continue to be pivotal in achieving operational excellence across industries, driven by ongoing technological advancements and an ever-growing range of applications. Their ability to provide reliable, efficient, and precise control of hydraulic fluid makes them an invaluable asset in the pursuit of optimized industrial processes. As industries evolve and new challenges arise, the adaptability and innovation surrounding hydraulic cartridge valves will undoubtedly foster continued growth and development in hydraulic engineering, ensuring their relevance in future applications.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!