Hydraulic Cartridge Valves are fundamental components in hydraulic systems, providing control over fluid flow and pressure. Often used in mobile equipment, industrial machinery, and material handling, these valves are integral to ensuring operational efficiency. This article delves into their function, types, and applications across various sectors, offering expert insights into their strategic importance in modern engineering.

Introduction to Hydraulic Cartridge Valves

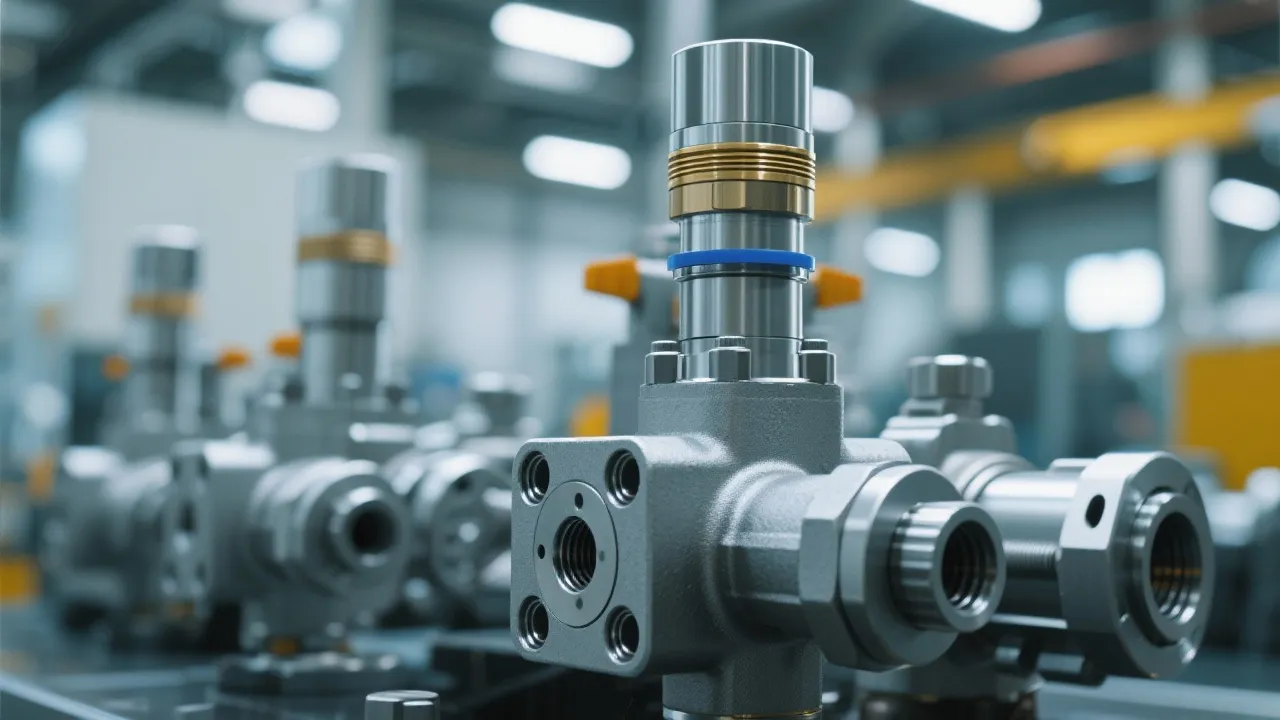

Hydraulic cartridge valves are essential elements in fluid power systems, acting as the crucial regulators of hydraulic flow and pressure. Named for their cartridge-like design, these valves are seated directly in a manifold, offering compact and efficient solutions for hydraulic control. Their versatility and reliability make them indispensable in various sectors such as automotive manufacturing, aerospace, agricultural machinery, construction, and heavy equipment. The ability to control fluid dynamics with precision adds significant value to systems reliant on hydraulic technology, thus reaffirming their role as a critical component in modern engineering.

Functionality and Design

At their core, hydraulic cartridge valves enable precise control of hydraulic fluid, which is critical in powering and controlling machinery. Their design typically includes an enclosed disc or piston within a cartridge housing, allowing for smooth and efficient regulation of flow paths. The choice of materials used in constructing these valves is vital. High-grade steel, aluminum alloys, and specialized polymers are common materials that withstand high pressures and resist wear, ensuring longevity and reliability even in harsh operational environments. Additionally, their design often features interchangeable components, allowing for customization and adaptation to a wide range of applications, which enhances their functionality considerably.

Types of Hydraulic Cartridge Valves

There are several types of hydraulic cartridge valves, each serving distinct functions:

- Pressure Control Valves: These regulate the pressure within hydraulic systems to prevent leaks and potential system failure. They can be further categorized into relief valves, which protect systems from overpressure conditions, and sequence valves, which ensure processes occur in a specific order by controlling fluid pressure.

- Flow Control Valves: Essential for dictating the rate of flow, ensuring machinery operates with optimal precision. They can help adjust speed in hydraulic actuators and control circuit performance in various applications.

- Directional Control Valves: Used to direct hydraulic fluid to specific locations within the system, allowing for directional control in hydraulic circuits. These valves can be manual, mechanical, or electrically actuated and are crucial in machinery with multiple actuating parts.

- Check Valves: Prevent backflow, maintaining system integrity by ensuring fluid flows in a singular direction. Variants include spring-loaded, ball, and poppet check valves, each suited to different control requirements.

- Flow Dividers: These sophisticated valves split the flow of hydraulic fluid into multiple pathways, allowing for simultaneous operation of various actuators while maintaining equal pressure and flow rates across outputs.

- Soft Start Valves: Designed to gradually introduce fluid into the system, soft start valves help mitigate shock loads typically associated with sudden pressure changes, enhancing system stability during startup.

Applications in Various Industries

The adaptability of hydraulic cartridge valves makes them vital across numerous industries:

- Automotive: Integral in assembly lines, ensuring consistent performance and safety in vehicle manufacturing. Functions range from managing braking systems to operating hydraulic lifts for vehicle assembly.

- Aerospace: Precision and reliability in hydraulic systems are critical for avionics and navigational controls, where even a minor failure could lead to significant operational risks.

- Agricultural Equipment: From tractors to plows, these valves enhance the efficiency of machinery used in farming activities, allowing for precise control of equipment movements, improving both productivity and safety.

- Construction: Heavy machinery such as excavators depend on hydraulic systems to support complex operations and movement. Hydraulic cartridge valves are crucial for controlling boom movements, bucket actions, and stabilizer operations.

- Marine Applications: In marine environments, hydraulic systems are entirely reliant on cartridge valves for controlling critical functions such as steering, propulsion, and deck machinery operations.

- Mining: Hydraulic cartridge valves are employed in drilling rigs, haul trucks, and crushing machines, enabling precise control over heavy machinery used in extracting minerals.

Advantages of Hydraulic Cartridge Valves

The usage of these valves offers numerous advantages, including:

- Space Efficiency: Their compact design allows for easy integration into systems without compromising on space or performance. This compact nature is especially advantageous in applications where every inch of space counts.

- Cost-Effectiveness: Reduced installation costs and their longevity make them a financially viable choice for companies. Moreover, the potential for lower energy consumption results in long-term operational savings.

- Versatility: Applicable in multiple configurations and systems, adapting to various industrial demands. Their compatibility with diverse hydraulic fluids also enhances their usage across different industries.

- Enhanced Performance: The use of cartridge valves minimizes the number of connections needed in a system, reducing potential leak points and enhancing the overall efficiency of hydraulic circuits.

- Ease of Maintenance: Maintenance and replacement are simplified due to the self-contained design of cartridge valves, allowing even non-specialized personnel to perform routine inspections and replacements.

- Customization: Most hydraulic cartridge valves can be tailored to specific application requirements, offering unique sizing options and functional attributes to meet diverse customer needs.

Factors to Consider When Selecting Hydraulic Cartridge Valves

Choosing the right hydraulic cartridge valve involves consideration of several factors:

- System Requirements: Understanding the specific pressure, flow, and directional needs of the system is paramount. Ensuring that the valve selected aligns with these specifications ensures optimal function and longevity.

- Environmental Conditions: Ensuring the valve's material can withstand conditions such as extreme temperatures, humidity, or corrosive substances can prevent premature failure and maintain performance levels necessary for seamless operations.

- Maintenance and Compatibility: Ease of maintenance and compatibility with existing systems are crucial. It’s essential to assess if the chosen valves are suitable for retrofitting in pre-existing hydraulic systems.

- Operational Efficiency: Consideration of how the valves will contribute to the system’s overall efficiency, including factors like flow rates, response times, and potential integration of digital monitoring systems to optimize performance.

- Manufacturer Reputation: Selecting valves from reputable manufacturers ensures quality and reliability, which are critical for maintaining hydraulic system performance. Assessing the manufacturer’s history of product performance can also enhance confidence in their products.

The Innovation and Future of Hydraulic Cartridge Valves

Innovation continues to expand the capabilities of hydraulic cartridge valves, with emerging technologies enhancing their efficiency and adaptability. For instance, the integration of smart technology and the Internet of Things (IoT) allows for real-time monitoring and remote management, making hydraulic systems more intelligent and responsive to dynamic operational requirements. These advances mean that organizations can monitor the health of their hydraulic systems continuously, predict maintenance needs, and prevent failures before they arise.

Additionally, advancements in manufacturing techniques, such as 3D printing, are being explored as potential solutions for producing lightweight, high-performance hydraulic valves. This can reduce costs, improve customization, and expand the range of applications for hydraulic cartridge valves in industries such as renewable energy, where efficiency is vital. Future innovations are likely to focus on improving energy efficiency, enhancing materials for better durability, and developing more compact designs for even greater space-saving capabilities in hydraulic systems.

FAQs

- What is a hydraulic cartridge valve? Hydraulic cartridge valves are self-contained components designed to regulate fluid flow and pressure within a manifold system. They function by controlling how hydraulic fluid is directed and managed in various applications.

- Why are they used? They provide precise control, are space-efficient, and reduce the complexity of hydraulic systems, making them ideal for various high-performance applications while enhancing overall efficiency and reliability.

- How do they differ from traditional hydraulic valves? Unlike traditional valves, hydraulic cartridge valves are designed to fit into specific manifold systems, allowing for higher customization and tailored solutions, ultimately improving system efficiency and reducing potential failure points.

- Are they customizable for different industries? Yes, manufacturers often offer customizable options to suit the specific requirements of different industries, enabling the design of valves that fit unique application needs and operational demands.

- What maintenance practices should be followed for hydraulic cartridge valves? Regular inspections should be conducted to check for wear and tear, ensure proper operation, and monitor for leaks. Additionally, keeping the fluid clean and at proper levels can significantly extend the life span of hydraulic cartridge valves.

- Can hydraulic cartridge valves be integrated with smart technology? Yes, many modern hydraulic cartridge valves can be integrated with smart technology, allowing for better monitoring, diagnostics, and control through IoT solutions.

- What is the expected lifespan of hydraulic cartridge valves? The lifespan can vary based on usage conditions, materials, and maintenance practices. However, with proper care and use within specified limits, many hydraulic cartridge valves can last for several years, often exceeding a decade.

Conclusion

Hydraulic cartridge valves are a cornerstone of modern hydraulic systems, providing vital functionalities that enhance control, efficiency, and safety across a myriad of applications. Understanding the various types, their applications, and the innovations shaping their future can help engineers and operators make informed decisions when designing and maintaining hydraulic systems. As technology continues to advance, the role of hydraulic cartridge valves will only become more integral to the performance and reliability of hydraulic-powered systems, emphasizing the need for ongoing education and adaptation in this rapidly evolving field.