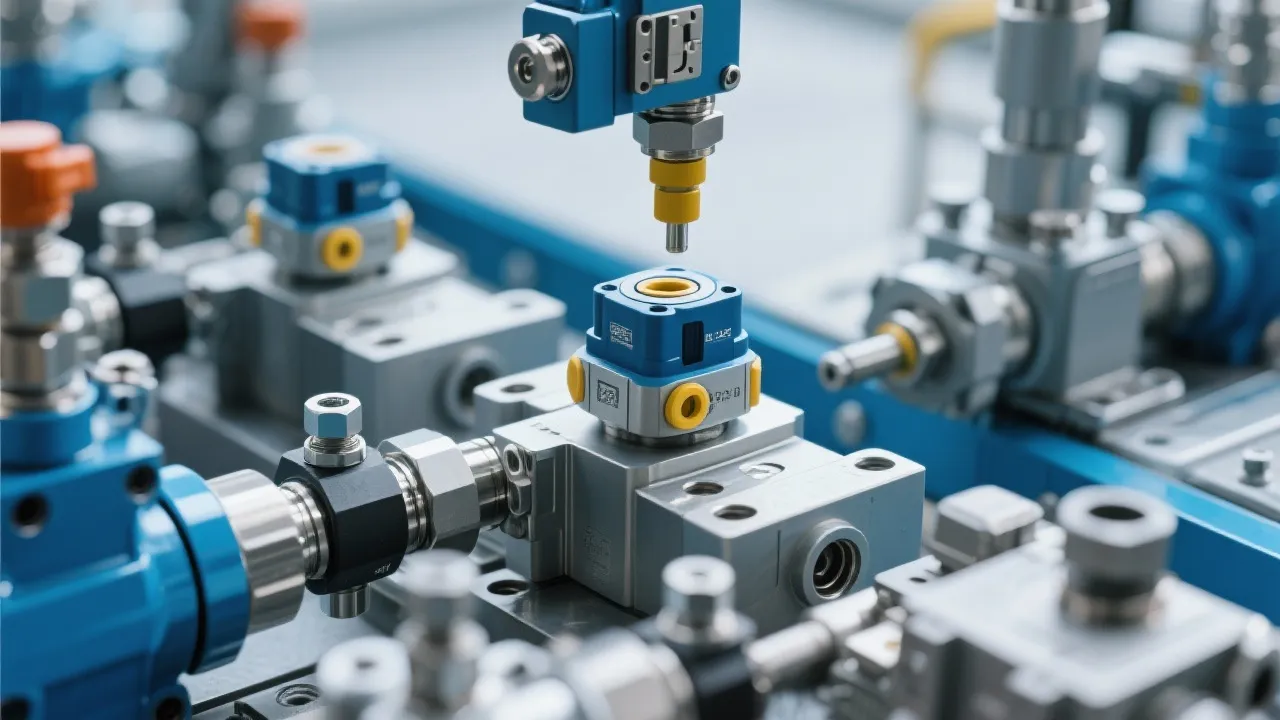

This guide provides a comprehensive overview of hydraulic cartridge valves and their role in industrial applications. Known for their efficiency in controlling fluid power, these valves are integral to machinery and automation. Readers will gain insights into various types, the advantages they offer, and their significance in modern engineering.

Hydraulic cartridge valves are critical components used to control the flow and direction of hydraulic fluid within industrial machinery. These valves are compact, efficient, and designed to fit into complex systems where space is at a premium. They play a vital role in ensuring the smooth operation of various mechanical systems by regulating pressure and flow rates. As technology advances, these valves continue to evolve, offering improved performance and reliability. This is crucial in an era where precision engineering and efficiency are key to maintaining competitive advantage in industrial processes.

Hydraulic cartridge valves are extensively used across various industries, including manufacturing, agriculture, construction, and automotive. In the construction industry, for example, they are essential in heavy machinery such as excavators and bulldozers, where precise fluid control is critical for optimal performance. These machines rely heavily on hydraulic systems to perform tasks such as lifting, digging, and moving heavy materials. The use of hydraulic cartridge valves in such applications ensures that operations can be performed smoothly and safely, mitigating the risk of damages or operational failures.

In agriculture, these valves help enhance the efficiency of tractors and harvesters by ensuring a steady hydraulic flow for different attachments. Tractors require hydraulic systems to operate implements like plows, seeders, and loaders. By utilizing hydraulic cartridge valves, farmers can achieve better control over hydraulic functions, enabling more efficient planting, harvesting, and transporting of crops. This not only boosts productivity but also contributes to better resource management, ultimately leading to improved sustainability in agricultural practices.

Moreover, these valves are increasingly finding applications in automotive systems, particularly in advanced vehicles equipped with various hydraulic-driven features such as power steering and braking systems. In these scenarios, hydraulic cartridge valves assist in achieving responsive and reliable braking performance, enhancing overall vehicle safety. Their role in automating processes cannot be overstated, as they facilitate the fine-tuning of movements in complex systems, allowing for enhanced operational capabilities and reduced human error in machine control.

The versatility of hydraulic cartridge valves is reflected in the wide array of types available, each serving a specific function:

One of the primary benefits of hydraulic cartridge valves is their compact size, which allows for integration into systems with limited space. This is particularly advantageous in modern machinery, which aims to maximize efficiency without sacrificing performance. The compact design not only saves space but also minimizes the weight of hydraulic systems, contributing to overall energy savings during operation.

They also offer high levels of customization and can be tailored to specific operational needs. Manufacturers often work closely with engineers to design valves that meet unique specifications, whether it's a requirement for specific pressure ratings, flow rates, or even environmental conditions. This adaptability makes hydraulic cartridge valves ideal for diverse applications ranging from standard machinery to specialized industrial equipment.

Another notable advantage of these valves is their durability and low maintenance requirements, making them cost-effective over the long term. The robust materials and advanced engineering involved in manufacturing these valves contribute to their longevity, reducing the frequency and cost of replacements. This reliability is crucial for maintaining productivity in industries where machine downtime can result in substantial financial losses.

Furthermore, hydraulic cartridge valves can be easily replaced or serviced without extensive disassembly of the entire hydraulic system. This quick turnaround for maintenance tasks minimizes operational disruptions and makes it easier for technicians to perform routine checks and troubleshooting.

The hydraulic valve industry is experiencing several innovations aimed at enhancing efficiency and reliability. Recent advancements focus on the development of smart valves with sensors and electronic controls, allowing for remote monitoring and adjustments. This integration of technology signifies a shift towards more intelligent systems that can adapt to varying operational conditions and make automatic adjustments as needed to optimize performance.

Moreover, sustainability initiatives are prompting manufacturers to create valves that minimize fluid wastage and improve energy efficiency. The hydraulic sector is increasingly being called upon to reduce its environmental impact, leading to the development of valves that require lower fluid volumes and contribute to energy savings during operation. Innovations in material science are paving the way for more environmentally friendly options that do not compromise on performance. Additionally, manufacturers are focusing on producing valves that can withstand harsher environmental conditions, enhancing their versatility across various applications.

To better grasp the importance of hydraulic cartridge valves, we can consider several real-world case studies highlighting their applications across different industries:

In the construction sector, a leading manufacturer of excavators integrated hydraulic cartridge valves into its hydraulic systems. These valves were designed for enhanced durability and precise control, allowing the machinery to operate efficiently even in rough terrain. The result was a marked improvement in lifting capabilities and speed of operation, which led to decreased project timelines and improved overall productivity on construction sites. Feedback from operators indicated a significant reduction in manual errors attributed to the precise control enabled by the cartridge valves, thereby enhancing safety.

A major agricultural equipment manufacturer adopted hydraulic cartridge valves for its latest line of tractors. These tractors were designed to be more fuel-efficient and were equipped to handle various hydraulic attachments. The implementation of cartridge valves allowed farmers to achieve better variability in flow rates based on the attachment being used, leading to optimized harvesting processes. Additionally, the improved performance in hydraulic systems resulted in reduced fuel consumption, allowing for cost savings that farmers greatly appreciated during challenging economic times.

In the automotive sector, a car manufacturer utilized hydraulic cartridge valves in its power steering mechanism. The switch to cartridge valves enabled smoother steering control and improved overall vehicle responsiveness. Test drivers reported a more enjoyable driving experience, characterized by reduced steering effort and enhanced vehicle maneuverability. The new valve system's design also contributed to lower production costs and quicker assembly times, leading to better profitability for the manufacturer.

As technology continues to advance, the hydraulic cartridge valve industry must adapt to meet the changing demands of various industries. One of the significant challenges lies in the integration of smart technology into existing hydraulic systems. While many new machines are being designed with these innovations in mind, retrofitting older equipment with smart cartridge valves can present logistical and financial hurdles.

Moreover, ensuring compatibility between traditional mechanical systems and electronic components can be complex. Engineers must navigate issues related to power supply, communication protocols, and data integration. This task necessitates collaboration among engineers, software developers, and manufacturers to create seamless systems that do not compromise on safety or reliability.

Furthermore, the push for sustainability will require continuous innovation in materials and manufacturing processes. As regulations tighten around energy efficiency and environmental impact, manufacturers must invest in research and development to create hydraulic cartridge valves that meet these new standards. This also includes the adoption of recycling processes for end-of-life valves to reduce waste.

Hydraulic cartridge valves are components designed for controlling the flow and pressure of hydraulic fluid within a system. They are engineered to be compact and easily integrated into complex machinery, providing precise control over hydraulic functions.

Cartridge valves are typically more compact and easier to replace, offering greater flexibility and reduced maintenance needs. They also facilitate precise control of hydraulic systems, improving operational efficiency and safety.

Yes, they are designed for durability and require minimal maintenance. Their modular design allows for straightforward repairs and replacements, minimizing equipment downtime.

Absolutely! The latest innovations in hydraulic cartridge valves include the incorporation of smart sensors and electronic controls. These advancements allow for remote monitoring, real-time adjustments, and enhanced control over hydraulic systems, making them more efficient and responsive.

In conclusion, hydraulic cartridge valves are indispensable to modern industrial operations, offering efficiency, reliability, and adaptability across multiple sectors. As enterprises continue to seek greater automation and precision, the demand for these valves is expected to grow, driving further innovation in the field. The ongoing advancements and challenges create a dynamic landscape for hydraulic technology, with future developments likely setting new benchmarks for performance and sustainability in industrial operations.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!