Dive into the world of Rexroth Modular Valves and their pivotal role in hydraulic systems. Renowned for their versatility and precision, these valves are essential in regulating the flow and pressure within intricate hydraulic systems. Explore their functionality, significance in various industries, and how they ensure optimum operational efficiency across diverse applications.

When navigating the landscape of hydraulic systems, the importance of reliable and efficient components cannot be overstated. Among such critical components are Rexroth Modular Valves. These valves are epitomes of engineering precision, offering unparalleled control in hydraulic systems. Designed to regulate flow and pressure, they ensure the smooth and safe operation of numerous mechanical processes. The evolution and development of these valves reflect advances in technology and the ongoing need for high performance in fluid control.

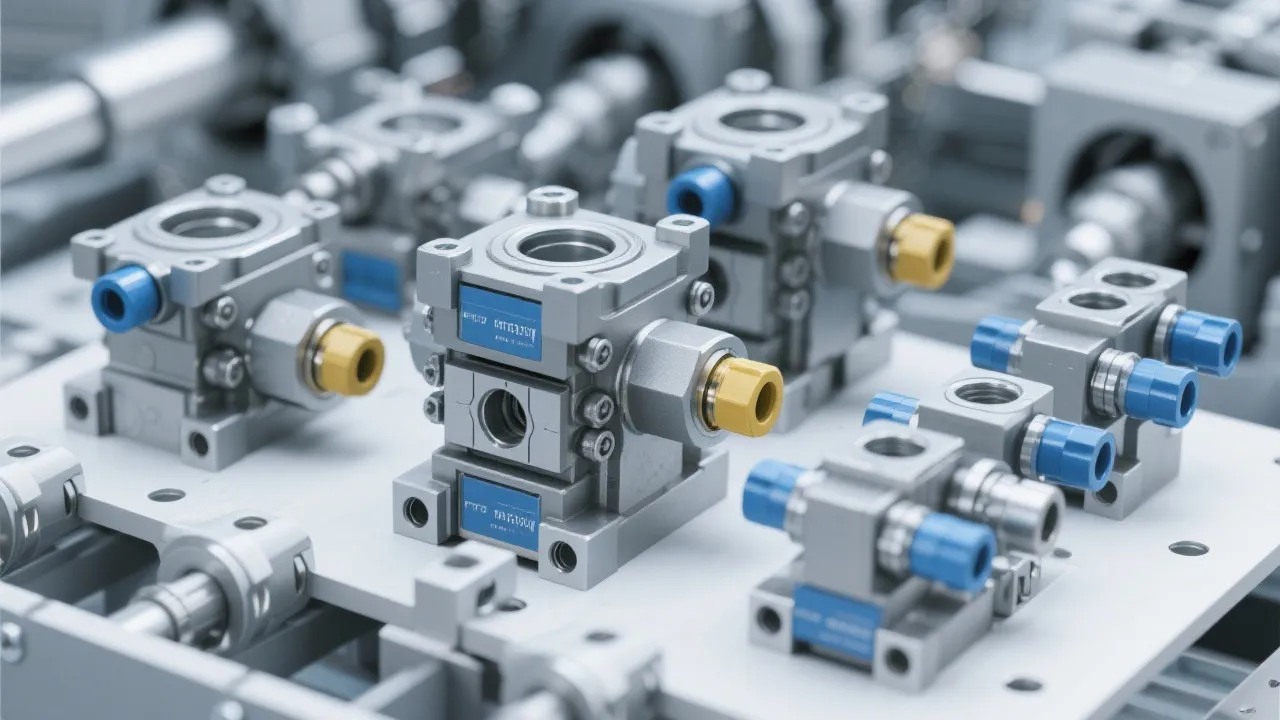

At the heart of any hydraulic system lies the requirement to effectively manage the movement of fluids. Rexroth Modular Valves address this need with their robust design and superior functionality. These valves are engineered to handle various pressures and fluid dynamics, making them indispensable in industries ranging from manufacturing to aerospace.

The modular design of these valves provides flexibility. This configuration allows for a range of functions, such as pressure control, flow control, and directional control, to be customized based on the system's specific needs. This adaptability is crucial for optimizing performance and maintaining system integrity in complex applications. By employing various components, users can assemble a valve configuration that best suits their specific needs, illustrating the importance of versatility in hydraulic systems.

Moreover, the integration of advanced materials and manufacturing techniques in the production of Rexroth Modular Valves enhances their performance. For example, utilizing high-performance seals and coatings can significantly improve the longevity and efficiency of the valves, ensuring they can operate under high-pressure conditions without failure or leakage. This factor is vital in industries continuously pushing the boundaries of operational efficiency and safety.

The versatility of Rexroth Modular Valves means that they are embraced across diverse sectors. In manufacturing, these valves are critical for machinery that relies on precision fluid control to produce high-quality outputs. For instance, in automotive manufacturing, hydraulic presses equipped with Rexroth Modular Valves are used to accurately shape metal components, demonstrating the need for precision in creating parts that meet exact specifications.

In the agricultural industry, they ensure the efficient operation of equipment used for irrigation and crop management. As agriculture pivots towards precision farming techniques, the role of these valves has become increasingly significant. Automated irrigation systems leverage Rexroth Modular Valves to deliver precise amounts of water and nutrients directly to plants, optimizing resource use and maximizing yield while conserving water.

Moreover, in the aerospace industry, where precision and reliability are non-negotiable, Rexroth Modular Valves provide the control necessary to operate various flight control systems and hydraulic actuators. Their ability to perform consistently in extreme temperatures and pressures underscores their engineering excellence. These valves are engineered to withstand the rigors of flight, which include severe temperature fluctuations and high stress during takeoff and landing.

Additionally, market trends have shown an increasing demand for automation within these industries, further elevating the significance of Rexroth Modular Valves. As more processes become automated, the need for reliable fluid control solutions continues to rise, prompting innovation and development within this product line. Their application expands into robotics, where fine control over movement and pressure is essential for precise operation.

The innovation behind Rexroth Modular Valves is not just limited to functionality; it's also about enhancing the user experience. Recent advancements in digital integration have paved the way for these valves to be equipped with smart technology. Integration of Industry 4.0 principles allows these valves to communicate with control systems, providing real-time data and diagnostics.

This digital transformation enables operators to monitor valve performance continuously and conduct predictive maintenance. Such capabilities reduce the likelihood of unexpected failures, ensuring systems remain operational and efficient. By analyzing data trends, companies can make informed decisions that align with their operational goals and enhance productivity.

Furthermore, improvements in design and materials have led to the development of energy-efficient solutions. As environmental considerations take precedence in modern engineering, the push for sustainable hydraulic solutions has gained momentum. Rexroth has responded to this need by creating valves that reduce energy consumption while maintaining high efficiency levels. This has far-reaching implications, especially in industries committed to reducing their carbon footprint.

To maximize the longevity and performance of Rexroth Modular Valves, implementing a regular maintenance schedule is essential. Proper maintenance practices not only enhance the efficiency of the hydraulic systems but also guarantee safety during operations. Common maintenance practices include regular inspections for wear and tear, checking for fluid leaks, and ensuring that seals and filters are in good condition.

Operators should be aware of any changes in valve performance, such as unusual noise, pressure fluctuations, or changes in flow rates. These signs often indicate underlying issues that need immediate attention to prevent more significant problems down the line. Conducting routine maintenance checks enables operators to identify potential faults before they escalate, saving costs related to repairs or replacements.

Additionally, cleaning the valves and their components from contaminants is crucial in maintaining their functionality. Dirt, dust, and debris can impede valve operation and lead to premature failure. Establishing clean working environments and using filtration systems can greatly minimize these risks, enhancing overall system reliability.

In conclusion, Rexroth Modular Valves are vital to the efficiency and reliability of hydraulic systems in various industries. Their precision, robust design, and adaptability provide essential fluid control, ensuring that systems function as intended and meet the demanding requirements of today's technical environments. As industries continue to evolve, the role of Rexroth Modular Valves will only grow in significance, driving innovation and advances in hydraulic technology.

Looking ahead, we can anticipate several trends that will shape the future of hydraulic systems and the use of Rexroth Modular Valves. As automation becomes more prevalent across industries, the integration of smart technologies will play an increasingly important role in fluid control systems. The advent of Industry 4.0 is revolutionizing the way manufacturers approach production, with real-time data and IoT (Internet of Things) devices providing unprecedented levels of insight and control.

In this landscape, Rexroth Modular Valves are poised to benefit from advancements in connectivity. Enhanced connectivity will facilitate better communication between various components of a hydraulic system, allowing for predictive maintenance and real-time adjustments to optimize performance. These capabilities will not only improve operational efficiency but also enhance safety and reliability, minimizing downtime.

Additionally, sustainability will continue to be at the forefront of industry priorities. As environmental regulations become more stringent and organizations aim to reduce their carbon footprint, the demand for energy-efficient hydraulic solutions will grow. Rexroth has already exemplified this commitment through innovations that minimize energy consumption while maintaining high standards of performance.

Another potential trend is the increased emphasis on modular design not just in valves but across hydraulic systems. As industries demand more flexibility and adaptability, the ability to create customized hydraulic solutions will be a significant competitive advantage. Modular components will enable businesses to quickly adapt to changes in demand or technology, ensuring they remain agile in a rapidly evolving marketplace.

Moreover, the ongoing development of materials science and engineering will drive further advancements in valve technology. Incorporating lighter, stronger materials can enhance valve durability while contributing to the overall efficiency of hydraulic systems. These innovations will be essential for applications like aerospace and automotive, where material weight and performance are crucial.

Lastly, collaborative robotics (cobots) is likely to influence hydraulic applications, prompting a need for systems that integrate easily with robots. As industries continue to explore collaborative approaches to manufacturing, hydraulic components such as Rexroth Modular Valves will need to support the seamless operation of robot-assisted processes.

The landscape of hydraulic systems is evolving at an unprecedented rate. Rexroth Modular Valves stand at the forefront of this evolution, embodying precision, reliability, and adaptability. As industries face new challenges and embrace innovative technologies, the role of these valves in ensuring efficient fluid control will remain paramount. Ongoing advancements in design, materials, and integration will only strengthen their position, making them critical components in the journey toward a more automated and sustainable industrial future.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!