Rexroth Modular Valves are integral components in hydraulic systems, providing flexibility and efficiency in controlling fluid flow. Known for their precision and reliability, these valves are essential in various industrial applications, facilitating system optimization and energy management. This article delves into the design, functionality, and benefits of using Rexroth Modular Valves in contemporary hydraulic systems.

In the realm of hydraulic systems, Rexroth Modular Valves stand out for their precise engineering and adaptability. These valves play a crucial role in controlling fluid flow within complex mechanical infrastructures, enhancing both operational efficiency and environmental sustainability. They are designed to meet the dynamic demands of diverse industries such as manufacturing, construction, and automotive, thus ensuring a high level of performance and reliability. The integration of advanced technologies and innovative designs has made Rexroth Modular Valves a preferred choice among engineers and system designers.

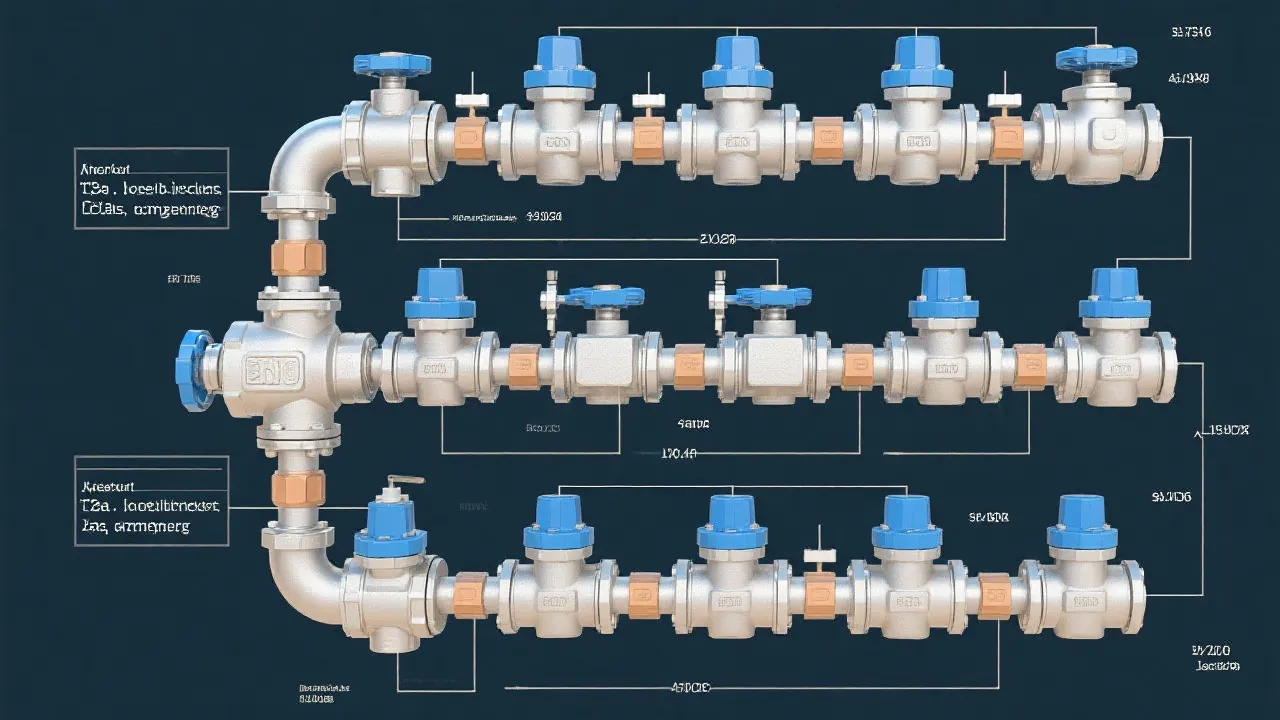

Modular valves are pivotal in managing hydraulic systems by regulating the pressure, flow, and direction of hydraulic fluid. This versatility makes them indispensable components in machines that require flexible and precise control. Rexroth, a renowned name in automation and control technologies, offers modular valves that can easily be integrated into existing systems, providing cost-effective solutions without sacrificing performance or durability. The modular design ensures that each component can be adjusted or replaced without needing to overhaul the entire system, thereby improving maintenance efficiency.

Rexroth Modular Valves are known for several key advantages:

Modular valves are available in several configurations depending on the application needs, including pressure relief valves, flow control valves, and directional control valves. Each type is designed to handle specific aspects of hydraulic systems, allowing for a tailored approach to system management. Understanding the distinct functionalities of these configurations is essential for selecting the right components for specific applications.

| Configuration Type | Description |

|---|---|

| Pressure Relief Valve | Regulates excess pressure to prevent system damage by diverting fluid or releasing it when automation exceeds predetermined limits. |

| Flow Control Valve | Adjusts the flow rate of hydraulic fluid, impacting speed and efficiency, which is vital for maintaining the desired operational speed of machinery. |

| Directional Control Valve | Determines the path of fluid within the system, crucial for operational versatility, allowing for different machine movements such as lifting, tilting, or rotating. |

Rexroth Modular Valves find their application across various industries, enhancing the functionality of equipment such as industrial presses, mobile machinery, and automation systems. They are an essential component in applications that require precise control and rapid response times. Here are some practical scenarios showcasing the advantages of Rexroth Modular Valves:

In industrial presses, modular valves control the hydraulic fluid that drives the pressing mechanism. By using flow control valves, operators can adjust the pressing speed and pressure, ensuring that products are manufactured with consistent quality and precision. Additionally, pressure relief valves prevent over-pressurization, safeguarding both equipment and personnel safety.

For mobile machinery, such as excavators and forklifts, Rexroth Modular Valves provide flexibility in control and operation. Directional control valves allow for multi-function hydraulic systems, enabling multiple operations to be performed simultaneously, which is crucial for enhancing productivity in dynamic working environments. For instance, while digging, an excavator can also maneuver its blade to stabilize or level the ground, effectively increasing its operational efficiency.

In automation systems, modular valves can adjust flow and pressure based on real-time feedback from sensors. This adaptability allows manufacturers to implement precise control over automated processes, significantly reducing the likelihood of errors and enhancing overall process efficiency. For example, in a bottling plant, the integration of Rexroth Modular Valves aids in maintaining the speed of filling and sealing processes, ensuring uniform quality across batches.

Modular valves also have critical applications in robotics, where they are used to precisely control the movements of robotic arms or legs in manufacturing lines or assembly processes. The high responsiveness and adaptability of Rexroth Modular Valves allow robots to perform intricate tasks requiring fine motor skills, achieving a higher level of automation and productivity.

An understanding of the technical aspects of Rexroth Modular Valves illuminates their role in hydraulic systems. The valves typically include components such as spools, actuators, and solenoids, all of which work synergistically to control fluid dynamics effectively. Here’s a breakdown of key components and their functions:

Rexroth Modular Valves are designed in adherence to various international standards, ensuring safety, performance, and compatibility within the global market. Compliance with standards such as ISO 4413 for hydraulic system safety and performance helps provide confidence to users about the reliability of the components. Additionally, these standards ensure that hydraulic systems are designed and operated to minimize the risks associated with hydraulic fluid leakage and component failure.

When selecting the appropriate modular valve for a specific application, several factors must be considered:

Regular maintenance of Rexroth Modular Valves is essential to maximize their lifespan and performance. Here are some key maintenance practices:

Q: What industries benefit the most from Rexroth Modular Valves?

A: Industries such as manufacturing, construction, automotive, and robotics significantly benefit from these valves due to their need for precise and reliable fluid control.

Q: How do Rexroth Modular Valves improve system efficiency?

A: These valves enhance efficiency by optimizing fluid control, leading to reduced energy consumption and improved operational performance across various applications.

Q: Can Rexroth Modular Valves be integrated into existing systems?

A: Yes, their modular nature allows for seamless integration into various systems, enabling easy customization and maintenance, which is particularly important in fast-paced industrial environments.

Q: What should I consider when selecting a Rexroth Modular Valve?

A: Application requirements, environmental conditions, integration capabilities, and future expansion needs should all be considered when choosing the right valve.

Q: How can I ensure the longevity of Rexroth Modular Valves?

A: Regular maintenance, fluid quality monitoring, and proper calibration are essential practices that ensure the longevity and optimal performance of Rexroth Modular Valves.

Rexroth Modular Valves are quintessential in modern hydraulic systems, offering unparalleled precision, flexibility, and efficiency. Their adaptability and efficiency make them essential across various industries, ensuring optimal performance and sustainability in operations. As industries continue to evolve, the demand for robust and adaptable solutions like these valves will undoubtedly increase, highlighting the importance of investing in quality components for sustainable growth and innovation. It is imperative for engineers and system designers to understand the capabilities and advantages of Rexroth Modular Valves to fully leverage their potential in achieving greater automation and efficiency.

The future of modular valves, especially in the context of Rexroth, looks promising as new technologies emerge. With the rapid development of smart technologies and Industry 4.0, modular valves are becoming increasingly important in creating interconnected and intelligent systems. Future advancements may include:

As automation technology keeps advancing, Rexroth Modular Valves will play a pivotal role in enhancing the efficiency and flexibility of hydraulic systems, paving the way for innovations that can transform industries and improve operational outcomes.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!