This guide delves into the technical intricacies of Rexroth Cartridge Valves, exploring their function, applications, and advantages in hydraulic systems. Known for their efficiency and durability, these valves are integral to optimizing performance and ensuring reliability in various industrial sectors, including manufacturing, automotive, and aerospace.

Rexroth Cartridge Valves are a pivotal component in modern hydraulic systems, renowned for their precision and reliability. These valves are commonly used to control the flow and pressure of fluids, thereby enhancing the performance and safety of machinery. With their robust design and adaptability, Rexroth Cartridge Valves find applications across diverse industries, including automotive, aerospace, manufacturing, and even renewable energy sectors. As industrial technologies evolve, the demand for high-performance hydraulic components, such as cartridge valves, continues to soar. This makes a thorough understanding of their operation, features, and applications more essential than ever.

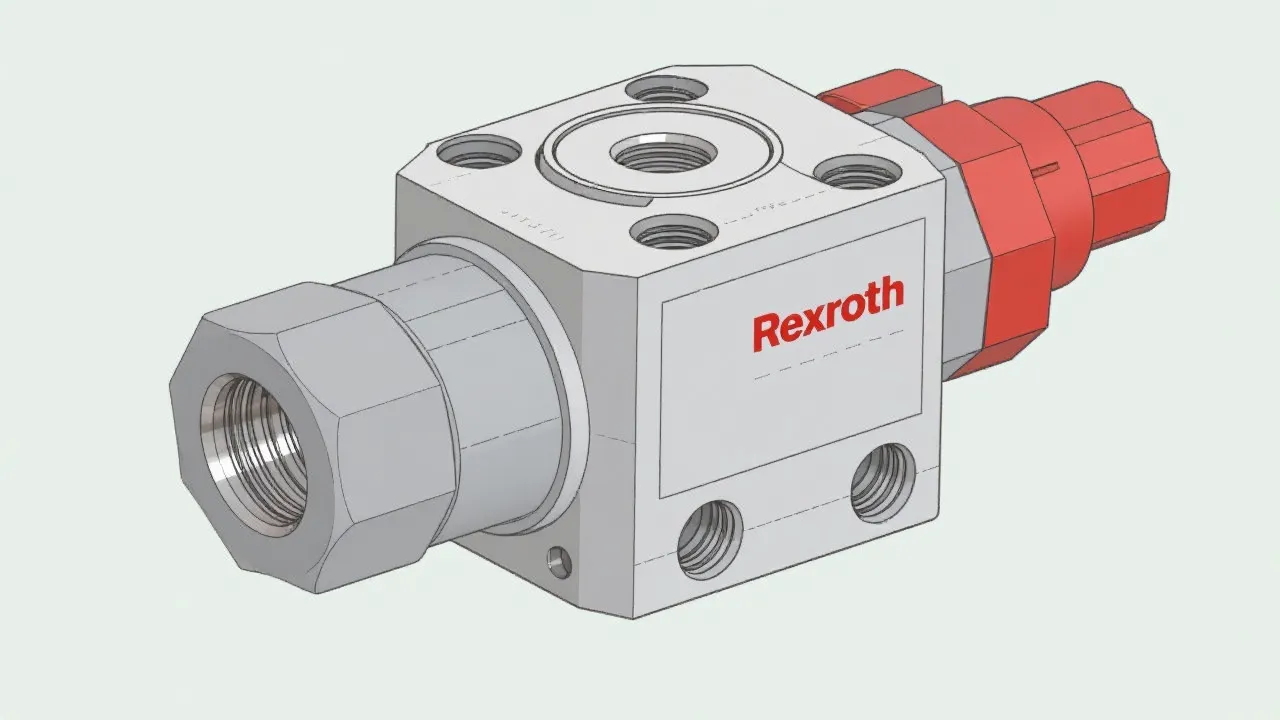

The standout features of Rexroth Cartridge Valves include their compact design, high flow capacity, and excellent sealing capacity. These attributes make them highly efficient in managing hydraulic circuits with a reduced footprint. Additionally, the durability and ease of maintenance associated with Rexroth valves ensure an extended service life and decreased downtime. A critical feature worth discussing is the incorporation of advanced materials in their construction, which enhances the pressure and wear resistance of these valves. This innovation not only increases lifespan but also contributes to the operational reliability of the systems they are integrated into. Furthermore, their modular design allows for simplified replacement and upgrading, making it easy to adapt the system to specific requirements or technology advancements.

Rexroth Cartridge Valves are extensively used in sectors where precision control and reliability are critical. In the automotive industry, they play a crucial role in advanced vehicle control systems, including automated driving and stability control. This allows for smoother operation and enhanced safety mechanisms, significantly benefiting vehicle performance and consumer trust. Meanwhile, in the aerospace sector, these valves manage hydraulic functions that require high precision and safety, such as landing gear operations, flight control surfaces, and cargo doors. The stringent regulations in aviation demand that components must offer exceptional reliability, which is achieved through the consistent performance of Rexroth Cartridge Valves.

Additionally, the versatility of Rexroth Cartridge Valves makes them suitable for complex machinery in manufacturing plants. Applications range from robotics and automated assembly lines to CNC machines and hydraulic presses. In these settings, effective fluid power management leads to optimal operational efficiency, reduced energy consumption, and lower operational costs. Their adaptability extends to mobile equipment, including agricultural machinery, construction vehicles, and material handling equipment, where environmental conditions can be challenging. Thus, Rexroth Cartridge Valves are instrumental in ensuring that industries can continually innovate while maintaining operational excellence.

Rexroth Cartridge Valves come in various configurations and sizes to accommodate specific application needs. Typical specifications include operational pressures up to 350 bar, flow rates that can exceed 600 liters per minute, and a resilience to temperatures ranging from -20°C to 120°C. Such specifications affirm their capability to perform under arduous conditions. Furthermore, they are designed to work with a variety of hydraulic fluids, enhancing their compatibility with existing systems and broadening their applicability. Another important technical aspect is their response time; many Rexroth models feature rapid actuation capabilities, allowing for quick adjustments in flow and pressure, optimizing system responsiveness in dynamic operations.

| Feature | Detail |

|---|---|

| Pressure Capacity | Up to 350 bar |

| Flow Rate | Exceeds 600 L/min |

| Temperature Range | -20°C to 120°C |

| Response Time | Rapid actuation for quick adjustments |

| Fluid Compatibility | Compatible with various hydraulic fluids |

Regular maintenance is crucial to maximize the service life of Rexroth Cartridge Valves. Routine checks for wear and tear can prevent unplanned downtimes and maintain optimal performance. It is advisable to adhere to manufacturer-recommended service intervals to prolong the operational efficiency of these valves. Regular inspections should include the examination of seals for wear, checking for leaks, and ensuring that the hydraulic fluid is clean and at the recommended levels. Implementing a consistent maintenance schedule not only extends the lifespan of the valves but also optimizes the overall hydraulic system’s efficiency.

Moreover, it's essential to ensure the cleanliness of the hydraulic environment. Contaminants like dirt and moisture can significantly degrade valve performance and lead to failures. Utilizing advanced filtration systems in conjunction with Rexroth Cartridge Valves can drastically improve reliability and maintenance outcomes. Keeping an eye on performance analytics can also be beneficial; by monitoring parameters such as pressure levels, flow rates, and system temperature, any deviations can be promptly addressed, leading to proactive rather than reactive maintenance strategies.

While Rexroth Cartridge Valves are known for their durability and efficiency, issues can arise during operation, often due to system malfunctions or improper maintenance. One common problem is flow restriction, which can occur due to blockages or misalignment. To resolve this, an expert should inspect the valve and the associated hydraulic circuit for any debris or alignment issues. Cleaning or realigning components usually restores optimal flow.

Another issue is excessive leakage. Leaks can result from seal degradation over time, which is why regular inspections are recommended. If a leak is detected, replacing the affected seals or—if necessary—the entire valve unit is vital to maintain system integrity. In the event of unusual noise during operation, this may indicate internal wear or cavitation. System pressure should be checked, and the valve may need to be disassembled and assessed for damage. Preventative practices, such as maintaining appropriate fluid hygiene and monitoring operational parameters, significantly reduce the occurrence of such problems.

As technology rapidly evolves, so too does the design and functionality of hydraulic components like Rexroth Cartridge Valves. Future advancements are expected to focus on increasing energy efficiency and integrating smart technologies into hydraulic systems. These technologies may include IoT (Internet of Things) capabilities, allowing real-time monitoring and data analytics to optimize valve performance. Predictive maintenance strategies supported by artificial intelligence could further enhance operational reliability, minimizing unexpected failures and maximizing system uptime.

In addition, there is an increasing trend towards environmentally friendly practices across industries. This includes the development of hydraulic fluids that are less harmful to the environment, as well as the design of valves that consume less energy during operation. Rexroth Cartridge Valves are expected to evolve to meet these demands, ensuring continued compatibility with “green” technologies and sustainable practices.

In conclusion, Rexroth Cartridge Valves are indispensable in today's industrial landscape, enabling complex hydraulic systems to function smoothly and efficiently. Their reliability, adaptability, and performance make them critical in various applications, from automotive to aerospace and beyond. For businesses aiming to enhance their operational capabilities, these valves offer a robust solution that promotes productivity and sustainability. Understanding the importance of proper maintenance and being aware of new technological advancements will ensure that users can fully leverage the benefits these advanced hydraulic components provide.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!