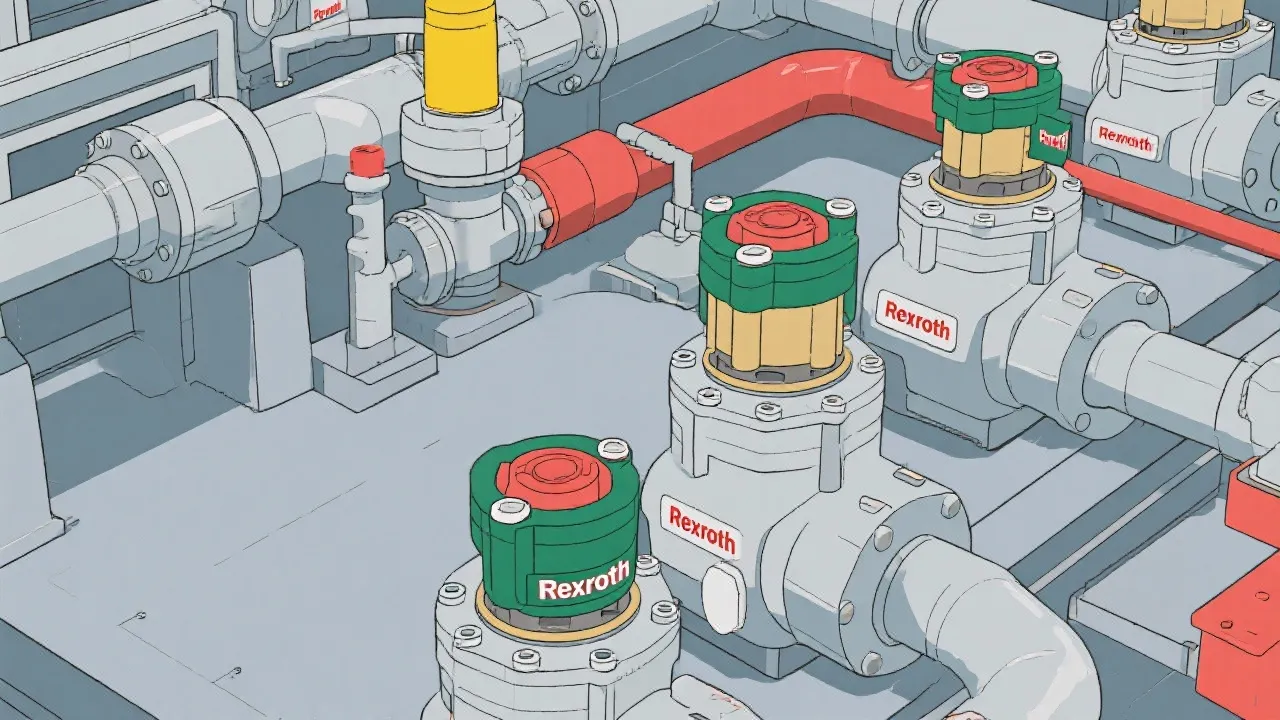

Understanding the Role of Rexroth Cartridge Valves in Modern Industries

The significance of Rxroth Cartridge Valves in hydraulic systems cannot be overstated. These components are expertly crafted to control fluid flow, pressure, and direction, ensuring that hydraulic systems perform efficiently and reliably. Predominantly used in sectors like manufacturing, automotive, and aerospace, their precision engineering sets them apart in a competitive landscape. These valves serve as the backbone of various hydraulic applications, lending themselves to complex operations that would be impossible without such refined technology.

The Evolution of Hydraulic Systems

Hydraulic technology has evolved dramatically since its inception in the early 20th century. Initially reliant on rudimentary mechanical systems, industries demanded more effective and efficient methods of power transmission. The development of hydraulic pumps and the introduction of sophisticated valves like those made by Rexroth transformed industries. Understanding this evolution is crucial to appreciate the modern valve's intricate design, which combines functionality with technological advancement.

Importance of Precision in Hydraulic Systems

At the heart of every hydraulic system's performance is the precision of its components. Rexroth Cartridge Valves are designed to handle various pressures and flows, offering unparalleled control over hydraulic circuits. This precision is crucial in applications where exact measurements influence outcomes, such as in automated manufacturing processes where consistency is key. Additionally, they provide the responsiveness needed to cope with sudden changes in pressure or flow, making them essential in systems where safety and performance are paramount. For example, in automotive assembly lines, these valves ensure that each component is accurately positioned and moved in a timely manner, directly impacting throughput and product quality.

Key Features of Rexroth Cartridge Valves

Rexroth Cartridge Valves stand out due to their:

- Robust Build: Designed to withstand harsh environments and rigorous operational demands, these valves often utilize materials like high-grade steel which offers excellent resistance to wear and corrosion. This ensures longer lifespans even under high-stress conditions.

- High Responsiveness: Quick response times are critical in applications requiring rapid fluid control adjustments. For instance, in agricultural machinery, the ability to react swiftly can make a difference in operational safety and efficiency.

- Compact Design: The engineers at Rexroth have focused on developing a compact valve profile that facilitates integration into systems where space is at a premium without sacrificing performance. This is especially beneficial in mobile applications, such as construction equipment, where every inch matters.

- Versatile Configuration: Rexroth Cartridge Valves can be configured for various flow rates and pressures, making them adaptable for multiple applications. This versatility allows for their usage in everything from minimalistic systems to complex hydraulic networks.

- Easy Installation and Replacement: Their cartridge design simplifies installation and maintenance, reducing downtime during service operations. This means businesses can keep productivity levels high without extended interruptions.

Industries Benefiting from Cartridge Valves

The scope of applications for Rexroth Cartridge Valves is vast, spanning several industries. In the industrial manufacturing sector, these valves contribute to seamless operations by enabling precise control over hydraulic machinery. The automotive industry benefits from the efficiency and reliability these valves offer in assembly lines and testing equipment, while the aerospace sector utilizes them for their lightweight and durable characteristics, ensuring safety and performance in aircraft systems. Beyond these fields, Rexroth Cartridge Valves are also increasingly used in:

- Agriculture: With the rise of precision farming, these valves contribute to enhanced control in tractors and harvesting machines, ensuring optimal performance and resource utilization. This allows farmers to operate machinery more effectively, leading to higher crop yields.

- Marine Applications: In the marine sector, where safety and reliability are critical, these valves control various hydraulic systems on vessels, ensuring smooth navigation and operation of essential equipment.

- Waste Management: Hydraulic systems in waste compactors and recycling facilities benefit from Rexroth Cartridge Valves as they provide powerful and efficient system control, crucial for environmentally sustainable operations.

- Robotics: In the burgeoning field of robotics, precise control over actuators is essential. Cartridge valves allow for sophisticated movements and functions that enhance performance and accuracy.

Effective Maintenance and Upkeep

To maintain the optimal performance of hydraulic systems utilizing Rexroth Cartridge Valves, regular inspection and maintenance are crucial. Operators should monitor signs of wear and perform routine checks to detect potential issues before they lead to system failure. Regular maintenance protocols should include cleaning, checking for proper fluid levels, and ensuring that filters are replaced when necessary. Additionally, special attention should be given to:

- Fluid Quality: Proper fluid cleanliness and adherence to manufacturer specifications for operation pressures and temperatures are also essential for prolonging valve lifespan. Using the correct hydraulic fluids will not only improve efficiency but also reduce wear on valve components.

- Temperature Monitoring: Overheating can be detrimental to hydraulic systems. Monitoring the temperature of the hydraulic fluid helps in preventing damage to valves and other components.

- System Testing: Routine hydraulic system testing should be performed to ensure that all components, including the valves, are functioning correctly. Pressure tests can reveal whether the system is operating within its intended specifications.

- Environmental Assessments: Checking the operating environment for factors like dust, moisture, and temperature extremes can inform maintenance schedules and practices, ensuring a proactive approach to upkeep.

Top Considerations for Selecting Rexroth Cartridge Valves

When selecting Rexroth Cartridge Valves for a specific application, several factors should be carefully considered. Understanding these factors can lead to better performance and efficiency in hydraulic systems:

- Application Requirements: Identify the specific hydraulic needs of the application. This includes understanding the force requirements, flow rates, and control precision. For example, high-speed applications may require valves with quicker response times.

- Compatibility: Ensure that the selected valves are compatible with other components within the hydraulic system, such as pumps and actuators. Incompatible components can lead to system inefficiencies and potential failure.

- Environmental Conditions: Assess the operational environment where the valves will be used. Will they be exposed to high temperatures, corrosives, or varying pressures? Selecting a valve with the right build and material will enhance durability and reliability.

- Cost vs. Quality: There is a balance to be struck between cost and the quality of the components. Investing in high-quality valves may incur a higher initial cost but can lead to long-term savings through reduced maintenance and longer lifespans.

- Supplier Reputation: Choose suppliers with a proven track record and solid support for their products. Reliable suppliers often provide better warranties, support, and resources for installation and maintenance.

Technological Advancements in Cartridge Valves

The field of hydraulic systems is constantly advancing, with Rexroth at the forefront of innovation in Cartridge Valve technology. Recent developments include:

- Smart Valves: Integration of sensors and smart technologies allows for real-time monitoring of valve performance, providing critical data that can inform maintenance schedules and system adjustments.

- Enhanced Energy Efficiency: New designs focus on reducing energy loss in fluid flow, contributing to lower operational costs and improved sustainability in industrial processes.

- Modular Designs: Developing modular cartridge valves allows for easier upgrades and more flexible configurations to meet changing operational demands.

- Advanced Materials: Innovations in materials have led to the production of valves that can operate effectively at extreme temperatures and pressures without compromising performance.

FAQs about Rexroth Cartridge Valves

- What makes Rexroth Cartridge Valves stand out in the market? - Their precision engineering and robustness tailored to diverse industrial applications.

- How frequently should these valves be maintained? - Routine checks as per manufacturer's guidelines, typically aligned with the system's usage intensity.

- Can these valves be used in custom applications? - Yes, their modular design allows for customization to fit specific application requirements.

- Are Rexroth Cartridge Valves suitable for mobile applications? - Absolutely. Their compact design and robust build make them ideal for a range of mobile machinery.

- What kind of feedback can you get from smart Rexroth Cartridge Valves? - Smart valves can provide data on flow rates, pressure fluctuations, and potential malfunctions, enabling predictive maintenance.

- What should I do if my valve fails? - Follow proper troubleshooting protocols to isolate the issue. Consult the manufacturer’s manual for specific guidance tailored to the valve model.

Conclusion

Rexroth Cartridge Valves are not just components but vital contributors to the efficiency and performance of hydraulic systems. Their robust design and precision make them indispensable across industries, playing a crucial role in the smooth operation of machinery. The importance of these valves extends beyond their functional capabilities; they represent a confluence of innovative engineering and practical application in hydraulic technologies. For those looking to optimize their systems, investing in Rexroth Cartridge Valves is a step toward reliability and efficiency, ensuring that operational excellence is maintained every step of the way.

This exploration into the nuances of Rexroth Cartridge Valves showcases their importance and functionality. As the industry evolves, so do the demands for more sophisticated hydraulic solutions, and Rexroth's offerings continue to meet these challenges head-on. Importantly, they pave the way for hydraulic systems of the future, promoting sustainability and improved performance in industries reliant on precise hydraulic control.